Pololu Blog »

Pololu Blog (Page 61)

Welcome to the Pololu Blog, where we provide updates about what we and our customers are doing and thinking about. This blog used to be Pololu president Jan Malášek’s Engage Your Brain blog; you can view just those posts here.

Popular tags: community projects new products raspberry pi arduino more…

Big price reduction of Pololu MEMS sensor carriers and IMUs

We have some very exciting price reduction news to share with you, but first:

A little background

|

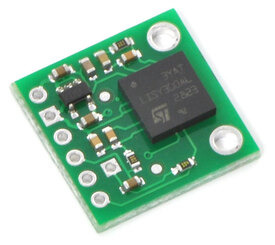

3-axis accelerometer carrier, released 22 Apr 2008. |

|---|

MEMS (Micro-Electro-Mechanical Systems) devices are everywhere today, from airbag crash sensors to smartphones to inkjet printer heads, so it is easy to take this ubiquitous technology for granted without considering just how impressive it really is. The defining characteristic of a MEMS device is the presence of microscopic mechanical elements that are similar in size to the features of the electronics in an integrated circuit – if you look closely enough at the silicon of a MEMS inertial sensor, you will see tiny moving cantilevers or springs right alongside the electrical elements that let you interface with them.

Several of us here at Pololu fondly remember using our first MEMS sensors around the turn of the century (the “Y2K” one, not the horse-and-buggy one) as they became affordable enough to consider for our college engineering projects. At the time, it was around $20 for a single-axis accelerometer, and that seemed like a pretty sweet deal! Since then, widespread use of MEMS technology in mobile devices has led to rapidly improving performance and falling prices, putting some amazing technology well within the financial reach of students and hobbyists. However, these same market pressures favor compact, surface-mount ICs that can be integrated into ever-shrinking consumer products, making them very difficult to work with, and this is where we come in: our goal is to make these great sensors available to a much wider audience. We design and manufacture breadboard-compatible carrier boards for these MEMS ICs that include all of the additional required components along with voltage regulators and level-shifters that allow direct integration into 5V systems.

|

|

One side effect of this rapidly evolving technology is that if we want our MEMS products to remain relevant, we have to update them more quickly than our other products. For instance, our 3pi is approaching six years old, yet it is still a decent basic robot platform (see my stock 3pi dominate our recent LVBots maze-solving competition). In that same time, we have gone from our first MEMS carriers – a 3-axis accelerometer for $20 and a single-axis gyroscope for $30 – to a complete IMU with 3-axis accelerometer, 3-axis magnetometer, 3-axis gyro, and pressure sensor, each with performance much better than those earlier units.

So far, we have generally kept our prices the same or had modest decreases as we have released newer units with higher performance, but today we are announcing significant price cuts to our latest-generation boards:

|

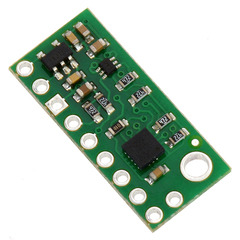

The LSM303D 3D compass and accelerometer carrier is now $9.95, down from $14.95. This inertial sensor consists of a 3-axis accelerometer and a 3-axis magnetometer in a single package.

|

The L3GD20H 3-axis gyro carrier is now $12.95, down from $19.95. This inertial sensor measures the angular rates of rotation about the roll, pitch, and yaw axes.

|

The MinIMU-9 v3 is now $19.95, down from $39.95. This IMU module features an LSM303D 3D accelerometer+magnetometer and L3GD20H 3D gyro, providing nine independent rotation, acceleration, and magnetic measurements that can be used to calculate the module’s absolute orientation.

|

The AltIMU-10 v3 is now $27.95, down from $49.95. This IMU module is equivalent to a MinIMU-9 v3 with an integrated LPS331AP pressure sensor, providing ten independent pressure, rotation, acceleration, and magnetic measurements that can be used to calculate the module’s altitude and absolute orientation.

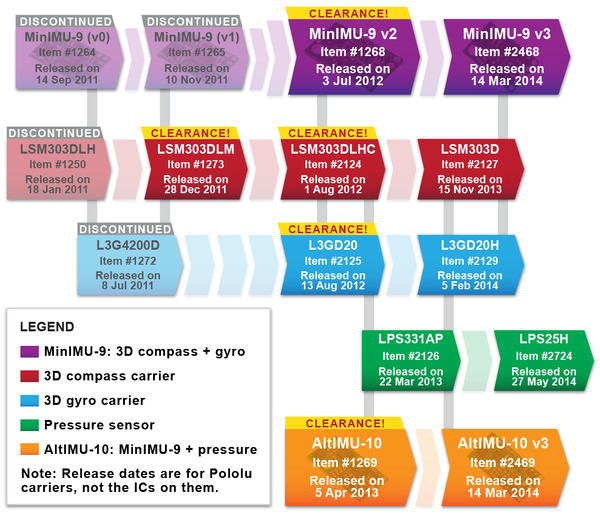

This fast technology progression makes planning challenging – it sometimes takes six months or more from the time we order a newly-announced component to when it arrives, and by the time we get it and build a board around it, the next great part is announced. This leads to a somewhat complicated lineage of products in various life-cycle stages. The following diagram shows the progression of our products based on ST’s MEMS sensors, which we have been most excited about lately thanks to their digital interfaces and many user-configurable settings:

|

Evolution and release dates of Pololu carriers for ST’s MEMS sensors through May 2014. |

|---|

The constant product refreshing also leaves us with older-generation boards that we generally put on clearance. We have decreased the clearance prices of these products so they remain compelling lower-price alternatives to the latest-generation boards. These boards are not recommended for new designs where continued availability is important, but if you just want to play around with a cheap sensor that was state-of-the-art a few years ago, these are a great deal while they last:

|

The LSM303DLM 3D compass and accelerometer carrier has a new clearance price of $5.95.

|

The LSM303DLHC 3D compass and accelerometer carrier has a new clearance price of $7.95.

|

The L3GD20 3-axis gyro carrier has a new clearance price of $9.95.

|

The MinIMU-9 v2 has a new clearance price of $14.95. This IMU module features an LSM303DLHC 3D accelerometer+magnetometer and L3GD20 3D gyro.

|

The AltIMU-10 has a new clearance price of $22.95. This IMU module is equivalent to a MinIMU-9 v2 with an integrated LPS331AP pressure sensor.

New products: Adafruit NeoPixel rings

|

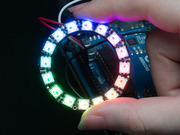

Continuing with our recent LED product line expansion, we now offer several of Adafruit’s NeoPixel rings. These addressable RGB LED rings are available in a 1.75″-diameter 16-LED ring, a slightly larger 24-LED ring, and as 15-LED quarter-rings that can be assembled into a large 60-LED ring.

|

|

|

The NeoPixels are effectively WS2812B RGB LEDs that are individually addressable and controllable by a single digital pin from a microcontroller. Multiple rings can be chained together, and the rings can be chained with our other WS281x-based LED products. The animated picture below shows the three different sizes of rings we carry connected in a single chain and controlled by a single pin from an A-Star 32U4 Micro, which is small enough to fit completely within the smallest ring.

|

Video: LVBots May 2014 maze solving competition

On May 29, LVBots held a maze solving competition at Pololu. The goal in maze solving is to get from the start to the finish in the shortest time. Contestants had four tries to solve the maze. The first run is typically in a learning mode where the robot goes slowly and explores the maze. On subsequent runs, the robots would attempt the shortest path, and the best robots had progressively more aggressive speeds.

I would have liked to see one of the custom-built robots win, but despite their best attempts, none of the other competitors were able to beat a stock 3pi robot running Ben’s maze solving code from six years ago. The old video below demonstrates how the 3pi solves a maze and also describes how the course is built.

This year, we tried to hone our rules about robots cutting corners of the maze. No robot will follow the line perfectly, so we have to allow some corner-cutting, but we do not want to make it so lax that the robot could dead reckon directly to the finish. After a lot of debate, we settled on two rules:

- A designated point on the robot must not go past the walls of an imaginary 6″-wide corridor centered around the path.

- The whole robot needs to generally follow the same path through the maze.

It was exciting to see Paul’s robot, Dr. Maze, use dead reckoning to cut the corners. Paul was hoping to get away from line following and rely on encoders to navigate the maze. Unfortunately, this caused the robot to get lost on the long straightaway and fail to solve the maze. Dr. Maze exhibits its corner-cutting skills at the end of the first video.

Are you in the Las Vegas area? Check out the LVBots Meetup page to get involved.

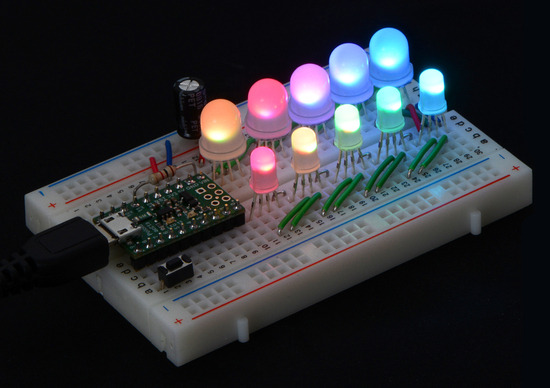

New products: Discrete addressable through-hole RGB LEDs

|

A chain of addressable RGB LEDs (#2535 and #2536) on a breadboard, controlled by an A-Star 32U4 Micro. |

|---|

At first glance, these new LEDs look like everyday through-hole RGB LEDs, but they are hiding something very special inside: a built-in WS2811 LED driver that lets you chain them together and individually control them all with a single digital output from a microcontroller. The communication protocol of these LEDs is very similar to that of our WS2812B-based LED strips and Adafruit’s NeoPixels (such as those on the Adafruit NeoPixel Shield, which we just started carrying last week), so there is a variety of sample code available for the Arduino, AVR, and mbed microcontroller platforms to help you make your project start blinking quickly.

We offer these LEDs in two different sizes: 5 mm and 8 mm.

|

Two different sizes of addressable RGB LED. From left to right, their diameters are: 5 mm (#2535) and 8 mm (#2536). |

|---|

ORBIS - Wooden Kinetic and Lighting Sculpture

Guido Bonelli Jr. of Innovative Electronic Solutions LLC created the ORBIS Wooden Kinetic and Lighting Sculpture for a client’s home using our custom laser cutting services. ORBIS hangs at 24″ in diameter and is 3/4″ thick. We laser-cut the parts from 1/8″ and 1/4″ baltic birch plywood, which were stained before assembly.

The separate control box and the wall unit each contain an Arduino Mega 2560 and an XBee module for wireless communication. The control box allows users to pick between two modes to control different features of the sculpture: kinetic mode allows users to adjust the rotating speed and direction of the two rings of the sculpture, and the color changing mode allows users to select various automated color patterns or control the red, green, and blue values individually to pick from 16 million colors.

|

|

For more information about ORBIS, check out the project’s web page.

New product: Adafruit NeoPixel Shield for Arduino

I love LEDs and all of the shiny, blinky, colorful things you can do with them (see what we did to my house last Christmas), so you can imagine how happy it makes me that we are now carrying Adafruit’s NeoPixel Shield for Arduino! With 40 individually addressable, WS2812B-based RGB LEDs all controlled by a single Arduino pin, this shield is effectively like a grid version of our addressable RGB LED strips. And just like our LED strips, multiple NeoPixel shields can be chained together into larger arrays. Controlling the LEDs is easy with the help of the compatible Arduino libraries, which include the Adafruit NeoPixel and NeoMatrix libraries, as well as our Arduino library for addressable RGB LED strips. This shield is a great way to add color, style, or functionality to your next Arduino project!

For more information on the NeoPixel shield, see the product page.

Free magazines: June 2014 Circuit Cellar and Elektor

|

|

Get FREE copies of Circuit Cellar magazine’s June issue and Elektor magazine’s June issue with your order, while supplies last. To get your free issues, enter the coupon codes CIRCUIT0614 and ELEKTOR0614 into your shopping cart. Each magazine will add 6 ounces to the package weight when calculating your shipping options.

For back issues and more information, see our free Circuit Cellar magazine offers and free Elektor magazine offers.

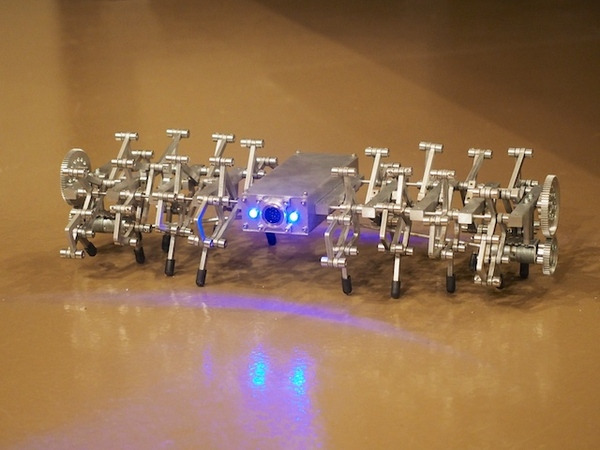

Aluminalis, a sixteen-legged walking robot

|

The Beatty family is at it again with their amazing robot builds (if you missed it, check out their Mars Rover). They completed Aluminalis, a sixteen-legged walking robot made mostly out of machined aluminum components.

The video above shows their magnificent sixteen-legged walking robot. It is all controlled by an Arduino Nano and uses Pololu 20D 73:1 metal gearmotors with matching brackets to move all of its aluminum legs.

For more information on Aluminalis, check out its build page.

New product: FEETECH FS90R Micro Continuous Rotation Servo

|

Continuing with our recent theme of tiny new actuators, we are now carrying FS90R micro continuous rotation servos from FEETECH. Continuous rotation servos are standard hobby RC servos that have been modified for open-loop speed control instead of their usual closed-loop position control, and they make convenient drive systems for robots because they are effectively a motor, gearbox, and motor controller/electronic speed control (ESC) in a single compact package. They are also very easy to use as they can be connected directly to an RC receiver or controlled by a single microcontroller I/O line programmed to output RC servo pulses.

With a weight of just 9 g, the FS90R is the smallest servo we have come across that is manufactured specifically for continuous rotation. It has great speed and torque for its size (up to 130 RPM and 1.5 kg-cm at 6 V), and at only $5 per servo, it is a very simple and affordable way to add some motion to your next project. For comparison (or if you are looking for an alternative servo that offers position control), it is very similar in size, weight, speed, and torque to the Power HD Micro Servo HD-1900A.

For more information on the FS90R micro continuous rotation servo, see the product page. For other options, you can check out our full selection of continuous rotation servos or our entire RC servo category.

|

Continuous rotation servo size comparison. From left to right: SpringRC SM-S4303R, Power HD AR-3606HB, FEETECH FS5106R, Parallax Feedback 360°, Parallax (Futaba S148), and FEETECH FS90R. |

|---|

Related post: Understanding continuous-rotation servos and multi-turn servos

Zumo tennis ball collector

Forum user patman715 posted to the forum about his modified Zumo Robot. The video above shows a Zumo with a two-servo gripper and arm capable of lifting tennis balls into an on-board storage bin. It is all controlled by an Arduino Leonardo, and two of our 100:1 micro metal gearmotors (we suspect they are HP versions) seem to give it plenty of oomph for carrying around the extra load.