Pololu Blog »

Pololu Blog (Page 24)

Welcome to the Pololu Blog, where we provide updates about what we and our customers are doing and thinking about. This blog used to be Pololu president Jan Malášek’s Engage Your Brain blog; you can view just those posts here.

Popular tags: community projects new products raspberry pi arduino more…

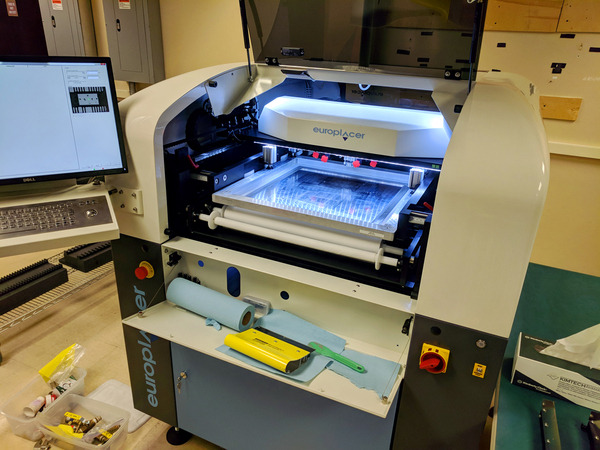

New equipment installation progress

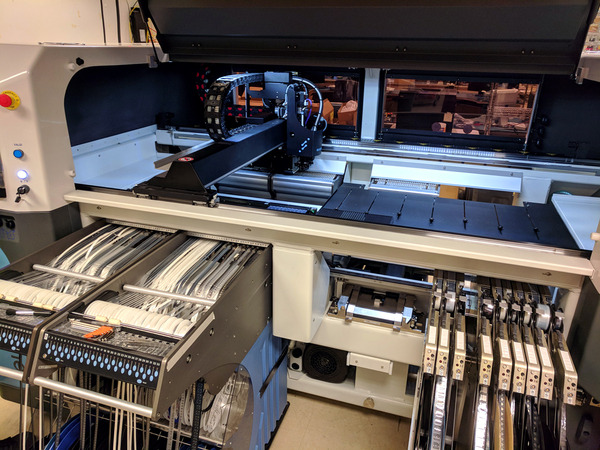

Some more of our new equipment showed up yesterday, and installation has been progressing all week. Here are a few more pictures.

|

Stencil printer selfie! |

|---|

|

New Europlacer pick and place machine on the left, older one on the right. |

|---|

|

Stencil printer ready for first print. |

|---|

|

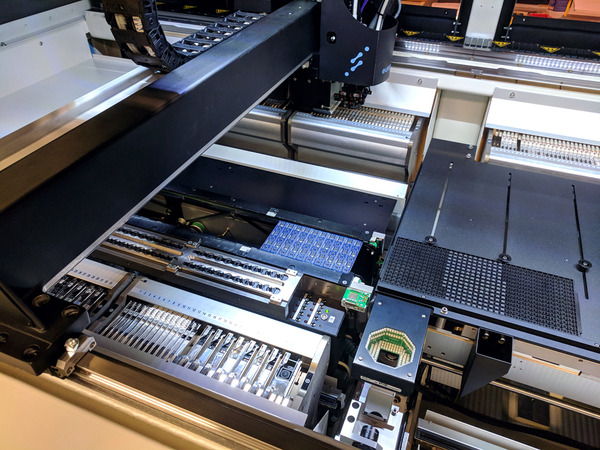

We like the Europlacer’s huge number of feeder slots. |

|---|

|

First production board on new Europlacer iineo+ pick and place machine, 7 February 2018. |

|---|

Europlacer’s iineo pick and place machine is one of the biggest and most versatile I know of, with space for up to 264 feeders (each feeder can hold a different component). For comparison, our Samsung pick and place machine, which itself has a decent feeder capacity compared to most machines, has 120 slots. We do not have any individual products that come close to requiring that many different components, but having such a huge feeder capacity means that we can run many different boards without having to change out a lot of parts. The feeders are also on carts that we can move around and between machines, which are also networked so that we can do things like set up new products on one machine and then run with the same setup on the other. I will write more soon about how this fits into our future plans, and about the other exciting new machine that is in the background of some of these pictures.

Picking and placing our new pick and place machine

We got a big delivery at Pololu yesterday. Here are some pictures for you to share in the excitement!

|

Seeing the truck pulling in with the crate on a flatbed trailer was a welcome sight after the difficulty last time, when we had to fish the crate lengthwise out of a covered trailer. |

|---|

|

|

Getting to uncrate the machine outside in short sleeves in January is just one of the perks of operating out of Las Vegas. |

|---|

|

|

|

|

Almost set for installation next week! |

|---|

I will post more about the machine and others we are installing once we have them up and running. For those of you wondering what it is, it is a pick and place machine, which is the kind of robot we use to build your robot parts. Here is a video of one of our existing machines in operation assembling a Zumo reflectance sensor array.

New Pololu Balboa T-Shirts!

|

Our new Balboa T-shirts are here! They feature our latest robot, the Balboa 32U4 balancing robot, within an enlarged outline of the 43-tooth gear option for the Balboa gearbox, accompanied by our call to “Engage Your Brain”. These pre-shrunk cotton shirts are available in several colors (navy blue, cardinal red, or black) and a range of youth and adult sizes.

|

|

|

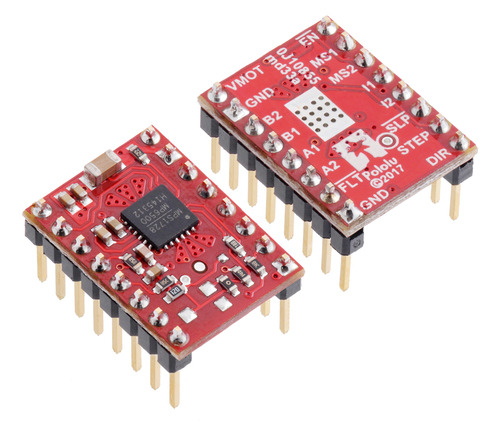

New products: MP6500 Stepper Motor Driver Carriers

|

|

We are excited to expand our colorful selection of stepper motor drivers with carrier boards for the brand new MPS MP6500 stepper motor driver!

Monolithic Power Systems’ MP6500 can drive a bipolar stepper motor from a 4.5 V to 35 V supply with up to 1/8-step microstepping. On our four-layer, 2 oz copper carrier boards, the MP6500 can deliver up to approximately 1.8 A per phase continuously without a heat sink or forced air flow, making this new module the highest-current stepper motor driver we carry among all the ones that share this form factor.

14 March 2018 Update: After further testing of more units, our initial characterization of the maximum continuous current capability was too high, so we have lowered it to 1.5 A. Please keep in mind that the exact maximum current you can get out of the driver at a given temperature will depend on your supply voltage and stepper motor characteristics.

|

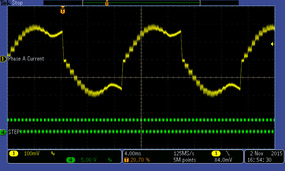

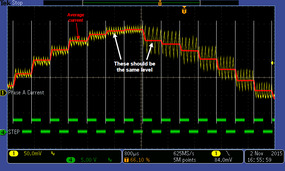

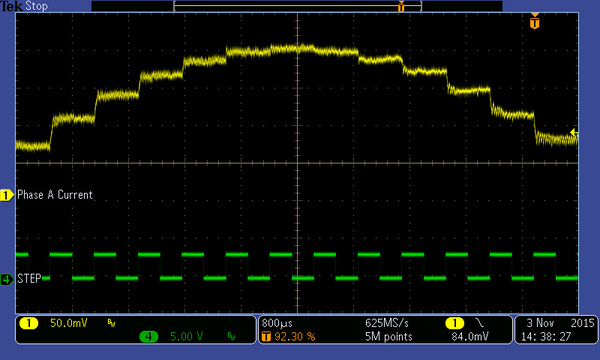

Unlike most other stepper motor drivers, the MP6500 features internal current sensing, which allows it to measure the motor’s coil current even during the off period of the PWM cycle. Combined with its automatic decay selection, this allows it to regulate the current especially accurately to produce smoother motion and higher speeds, as shown in the below oscilloscope capture from the MPS application note AN120 (1MB pdf).

|

Compare this with waveforms from a stepper driver that uses a more typical method of peak current control:

|

|

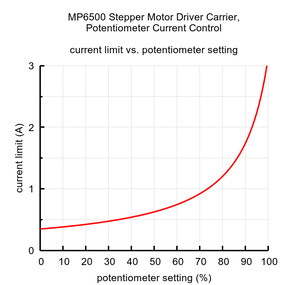

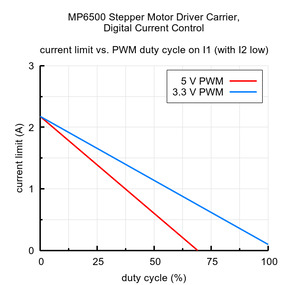

In addition to a version with potentiometer current control like most of our other stepper motor drivers, we also offer the MP6500 on a board with digital current control. This second version enables a microcontroller to dynamically set the current limit in steps of 0.5 A (up to a maximum of 2 A) by simply driving one or two inputs low. Alternatively, supplying an analog voltage or PWM signal allows finer control of the limit within the 0 to 2 A range.

Introductory special: just $2.97 each! Must use coupon code MP6500INTRO, limited to first 200 customers, limit 5 per customer.

Want to move heavy loads? We've got the linear actuator for you!

We have expanded our selection of Glideforce linear actuators from Concentric International to include their industrial-duty and medium duty series as steps up in power from their light-duty series that we have been offering for many years now.

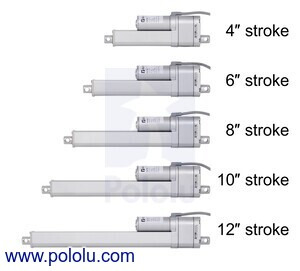

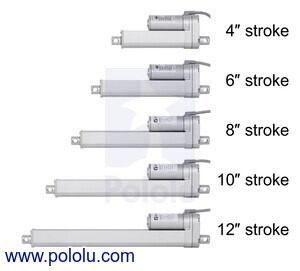

The medium-duty actuators are available in five different stroke lengths ranging from 4″ to 12″ and with or without feedback potentiometers, and they have a dynamic load rating of 225 lb, which means they can handle twice the load of their light-duty counterparts:

|

|

The industrial-duty actuators are real monsters compared to the medium-duty and light-duty units. The versions with an acme screw drive can handle dynamic loads up to 550 lb, and the versions with a ball screw drive (which is much more efficient than an acme screw) can handle dynamic loads up to a 1000 lb. Each drive option is available in six different stroke lengths ranging from 4″ to 24″ and with or without feedback potentiometers:

|

|

The following lets you compare all of our Glideforce linear actuator options:

| Actuator Type |

Max Dynamic Load |

No-Load Speed @ 12 V |

Current Draw @ 12 V |

Nominal Stroke Length |

With Feedback | Without Feedback | Approx. Weight |

|---|---|---|---|---|---|---|---|

| Light-Duty (LD) |

15 kgf [34 lbs] |

4.4 cm/s [1.7″/s] |

1.2 A – 3.2 A |

4″ | LACT4P-12V-05 | LACT4-12V-05 | 1.3 kg |

| 12″ | LACT12P-12V-05 | LACT12-12V-05 | 1.6 kg | ||||

| 50 kgf [110 lbs] |

1.5 cm/s [0.57″/s] |

2″ | LACT2P-12V-20 | LACT2-12V-20 | 1.2 kg | ||

| 4″ | LACT4P-12V-20 | LACT4-12V-20 | 1.3 kg | ||||

| 6″ | LACT6P-12V-20 | LACT6-12V-20 | 1.4 kg | ||||

| 8″ | LACT8P-12V-20 | LACT8-12V-20 | 1.5 kg | ||||

| 10″ | LACT10P-12V-20 | LACT10-12V-20 | 1.5 kg | ||||

| 12″ | LACT12P-12V-20 | LACT12-12V-20 | 1.6 kg | ||||

| Medium-Duty (MD) |

100 kgf [225 lbs] |

1.5 cm/s [0.58″/s] |

1.1 A – 4.6 A |

4″ | MD122004-P | MD122004 | 1.1 kg |

| 6″ | MD122006-P | MD122006 | 1.2 kg | ||||

| 8″ | MD122008-P | MD122008 | 1.3 kg | ||||

| 10″ | MD122010-P | MD122010 | 1.4 kg | ||||

| 12″ | MD122012-P | MD122012 | 1.5 kg | ||||

| Industrial-Duty (ID) with Acme screw drive |

250 kgf [550 lbs] |

1.7 cm/s [0.66″/s] |

2.4 A – 13.2 A |

4″ | LACT4-500APL | LACT4-500AL | 4.2 kg |

| 6″ | LACT6-500APL | LACT6-500AL | 4.4 kg | ||||

| 8″ | LACT8-500APL | LACT8-500AL | 4.7 kg | ||||

| 12″ | LACT12-500APL | LACT12-500AL | 5.3 kg | ||||

| 18″ | LACT18-500APL | LACT18-500AL | 6 kg | ||||

| 24″ | LACT24-500APL | LACT24-500AL | 7 kg | ||||

| Industrial-Duty (ID) with ball screw drive |

450 kgf [1000 lbs] |

1.7 cm/s [0.66″/s] |

2.4 A – 13.2 A |

4″ | LACT4-1000BPL | LACT4-1000BL | 4.6 kg |

| 6″ | LACT6-1000BPL | LACT6-1000BL | 4.9 kg | ||||

| 8″ | LACT8-1000BPL | LACT8-1000BL | 5.1 kg | ||||

| 12″ | LACT12-1000BPL | LACT12-1000BL | 5.6 kg | ||||

| 18″ | LACT18-1000BPL | LACT18-1000BL | 6.5 kg | ||||

| 24″ | LACT24-1000BPL | LACT24-1000BL | 7.4 kg | ||||

Note that we are currently out of stock of many of the industrial-duty versions, but we will be getting more as Concentric makes them available. For units where the expected lead time is several months, we have disabled backorders; please contact us if you are interested in placing an order now for one of those units.

To see all of our linear actuators, visit our linear actuator category.

Free USA shipping on hundreds of Pololu metal gearmotors

Since my last post about free shipping in the USA, we expanded the program to include orders consisting of $40 or more in free add-on shipping items. And today, we added almost 300 different metal gearmotors to our selection of products that ship for free in the USA. (Don’t worry, we don’t pile up actual good production motors like we did in that picture; those were returned by an infamous, once-skyrocketing startup.)

Closed December 25 and January 1

|

We will be closed for Christmas on Monday, December 25 and for New Year’s Day on Monday, January 1. Orders placed after 2 PM Pacific Time on December 22nd or 29th will be shipped on the following Tuesdays.

And last call for our Christmas sale — only about 15 hours to go!

Merry Christmas and happy New Year!

Pololu and LVBots CES Open House 2018

Are you attending CES or in Las Vegas on Wednesday, January 10th? You can join Pololu and LVBots any time from 5 p.m. to 8 p.m. for CES Open House 2018! Like last year, LVBots members will be showcasing their robotics and electronics creations, Pololu will be giving tours of our manufacturing and other operations, and you can present your company or your projects. We will provide food. Registration and other details are on the LVBots Meetup page.

(A Little More Than) Twelve Days of Christmas Sale

If you missed our Black Friday sale or realize you didn’t quite get everything you wanted, don’t fret: we have all active Pololu-brand and PCX products on sale for 12% off, and we are offering 20% off twelve broad categories of our products. The sale runs through noon PST on Friday, December 22, but be careful to order early for delivery before Christmas. Save on your Christmas shopping, or stock up now on robot parts for the new year. Check out the sale page for all the discounts and coupon codes. Merry Christmas!

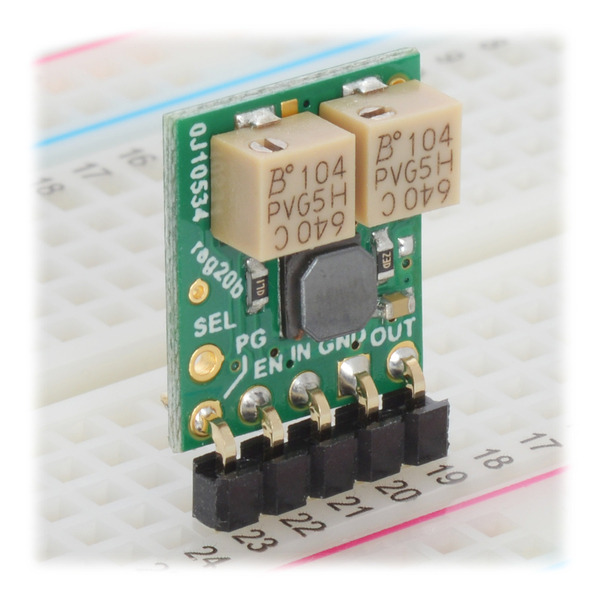

New adjustable voltage regulators with multi-turn fine adjustment

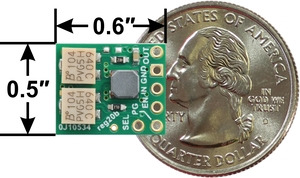

|

I am excited to announce our first voltage regulators with multi-turn trimmer potentiometers! I have wanted to add multi-turn pots to our products for a long time, but the problem has been that they are really expensive. They also tend to be quite big, at least compared to many of our boards, which we try to keep compact, and the smaller, surface-mounted ones are especially expensive. My latest round of looking for lower-cost options did not pan out, but I decided to just give it a try with the expensive parts.

The new S9V11x regulators that feature these potentiometers are buck-boost regulators that can output a voltage that is lower, the same, or higher than the input voltage. There are also versions with a multi-turn pot for adjusting the undervoltage cutoff threshold, so that if you use these with batteries, you can prevent overdischarging them. With twelve turns of adjustment available, it’s much easier to precisely set the voltages on the modules than with the single-turn potentiometers we have used on other adjustable regulators.

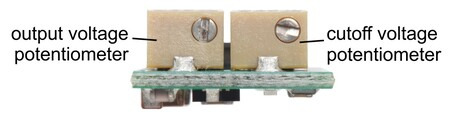

|

The output and cutoff multi-turn adjustment potentiometers on the S9V11x voltage regulators. |

|---|

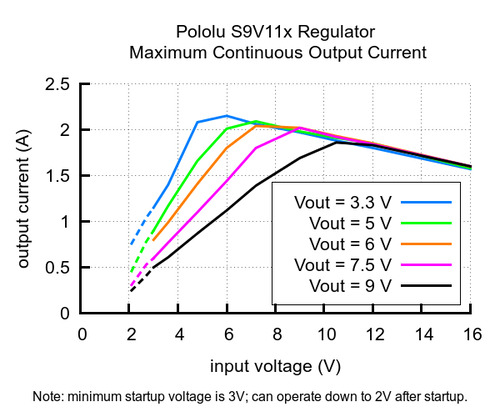

While I have been talking mostly about the potentiometers, the main regulator is pretty magical, too, giving you quite a bit of power over a broad operating input range in a small size.

|

Typical maximum continuous output current of Step-Up/Step-Down Voltage Regulator S9V11x |

|---|

Our stock products are available in several combinations of adjustable and fixed output voltage and cutoff. If you have a higher-volume application, we can make them with fixed voltages wherever you need them. You could initially prototype your design with the adjustable version and then get fixed ones made once you know exactly what voltage you need.

| Regulator | Input (V) | Output (V) | Low-voltage cutoff | Size | Price | |

|---|---|---|---|---|---|---|

|

#2868 S9V11MACMA | 2* – 16 | 2.5 – 9 (fine-adjust) | fine-adjust | 0.50″ × 0.60″ × 0.25″ | $19.95 |

|

#2869 S9V11MA | 2.5 – 9 (fine-adjust) | – | $14.95 | ||

|

#2870 S9V11F5S6CMA | 5 (6 V selectable) | fine-adjust | $14.95 | ||

| #2871 S9V11F3S5CMA | 3.3 (5 V selectable) | fine-adjust | $14.95 | |||

|

#2872 S9V11F3S5 | 3.3 (5 V selectable) | – | 0.50″ × 0.60″ × 0.17″ | $10.95 | |

| #2873 S9V11F3S5C3 | 3.3 (5 V selectable) | 3 V (fixed) | $10.95 | |||

|

#2836 S9V11F5 | 5 | – | 0.30″ × 0.45″ × 0.17″ | $11.95 | |

| * The regulator has a minimum start-up voltage of 3 V, but it can operate down to 2 V after startup. It is disabled when the input voltage is below the low-voltage cutoff. | ||||||

I am very interested to see what people think of the multi-turn adjustment feature. If these new regulators sell decently or customers ask for it, we will add the multi-turn potentiometers to our other regulator offerings. Is the extra expense worth it? Or do you know of a good, low-cost, multi-turn potentiometer we could consider for future products like this?