Linear Actuators » Glideforce Light-Duty (LD) Linear Actuators » 5:1 Glideforce LD Linear Actuators »

Glideforce LACT4P-12V-05 Light-Duty Linear Actuator with Feedback: 15kgf, 4" Stroke (3.9" Usable), 1.7"/s, 12V

This 12 V light-duty (LD) linear actuator with a 5:1 gear reduction can lift loads up to 15 kgf [34 lbs or 150 N] and can withstand static loads up to 250 kgf [550 lbs or 2500 N]. It has a maximum speed of 43.9 mm/s [1.73″/s] at no load and 36.5 mm/s [1.44″/s] at the maximum load. Limit switches at each end make the actuator easy to control over its full range of motion. The shaft holds its position when unpowered. This version has a 4-inch stroke (3.9″ usable) and a feedback potentiometer that lets you determine where the actuator is in its stroke.

Alternatives available with variations in these parameter(s): nominal stroke length feedback potentiometer included? linear speed @ 12V, no load Select variant…

| Description | Specs (18) | Pictures (10) | Resources (7) | FAQs (0) | On the blog (0) | Distributors (1) |

|---|

Overview

|

The Light-Duty (LD) series of Glideforce linear actuators by Concentric International (formerly Iowa Export-Import) are 12V DC gearmotors that use a lead screw to move a shaft back and forth along its length. The shaft will hold its position even when unpowered and subjected to static loads up to 250 kgf [550 lbs or 2500 N] for the LACT versions and 30 kgf [67 lbs or 300 N] for the GF23 versions. Two limit switches safely stop the motor at either end of its range, while integrated diodes allow it to reverse direction after reaching a limit point if the supplied voltage is reversed. The actuators have an all-aluminum frame and extension tube, and the entire case is sealed to protect against dust and water (rated IP65).

These actuators are available in several gear ratios and a variety of stroke lengths, from 2″ to 12″, and with optional potentiometers that are linked to the shaft position, for use in feedback systems. The table below shows all of the light-duty linear actuators we carry:

The following video demonstrates the speeds of the light-duty actuators:

Mounting brackets made from machined aluminum or stamped steel are available for attaching the actuators to a structure; two are required for each actuator (the aluminum brackets are sold individually while the steel brackets are sold in pairs).

Details for item #2319

|

Glideforce LACT4P-12V-x Light-Duty Linear Actuator with Feedback: 4″ Stroke. |

|---|

- Concentric item number: LACT4P-12V (sometimes also written LACT4P-12V-5)

- Nominal stroke length: 4″ [10.2 cm]

- Actual stroke length: 3.94″ [10.0 cm]

- Retracted length: 9.69″ [24.6 cm] (from mounting hole to mounting hole)

- Extended length: 13.62″ [34.6 cm] (from mounting hole to mounting hole)

- Weight: 41 oz [1.17 kg]

- Gear ratio: 5:1

- Rated dynamic load capacity: 34 lbs [15 kgf or 150 N]

- Speed at 12 V, no load: 1.73 in/s [43.9 mm/s]

- Speed at 12 V, max load: 1.44 in/s [36.5 mm/s]

- Feedback potentiometer

|

LD series features and specifications

The following specifications apply to all Glideforce LD series linear actuators:

- Nominal operating voltage: 12 V

- Maximum static load:

- 550 lbs [250 kgf or 2500 N] for LACT versions

- 30 kgf [67 lbs or 300 N] for GF23 versions

- Standard preset limit switches at both ends of stroke

- All aluminum frame and extension tube

- Noise level: ≤ 70 dB

- Mounting hole diameter: 1/4″ [6.4 mm]

- Working temperature: -13°F [-25°C] to 149°F [65°C]

- IP rating: IP65 (total dust protection, water resistant)

For more details, see the LACT datasheet (490k pdf) or the GF23 High-Speed datasheet (1MB pdf).

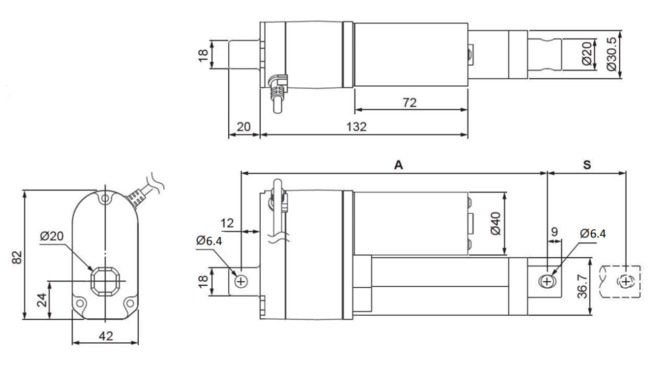

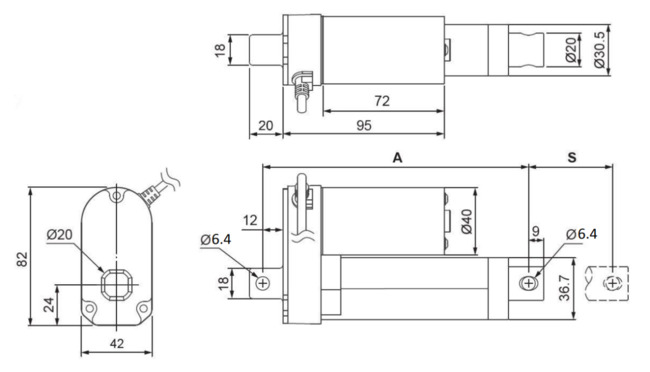

Dimensions

Diagrams of the linear actuators are shown below. The versions that include potentiometers have a larger gearbox, so their overall size and weight is larger. For more detailed information, including the retracted and extended lengths of each version, see the datasheet.

|

Dimensions of Glideforce LD linear actuators with feedback. Units are mm. |

|---|

|

Dimensions of Glideforce LD linear actuators without feedback. Units are mm. |

|---|

|

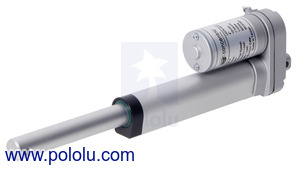

Glideforce Light-Duty linear actuator (4″ stroke) with shaft fully extended. |

|---|

Using the actuator

To test-drive the actuator, simply connect a power source of up to 12 V to the motor leads. Reversing the applied voltage will reverse the direction of motion. A motor controller or motor driver is required for electronic speed and direction control. We recommend our Jrk G2 21v3 or Jrk G2 24v13 motor controllers for use with the feedback actuators (see below for more information on this) and the Simple Motor Controller G2 18v15 for controlling the actuators without feedback, though many of our other motor controllers and motor drivers are capable of powering this actuator.

These actuators have a stall current of 7 A at 12 V, but they will, on average, draw far less than this when used within their load ratings. They draw around 1 A with no load and can exceed 3 A at their maximum rated dynamic load, so we have found they generally work well with our lower-power jrk 21v3 motor controller with feedback (see the bottom of this page for more information using this controller for closed-loop linear actuator position control). Note, however, that the actuators can briefly draw close to their full stall current when abruptly started or on a sudden change of direction. Such current spikes can be dampened if you take steps to limit the acceleration of the actuator (many of our motor controllers offer optional acceleration limiting).

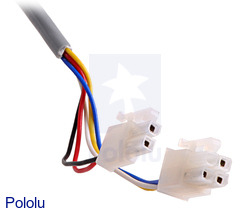

Actuator leads

Actuators with feedback have a 24″ (60 cm) cable that is terminated with special female connectors as shown in the left picture below, one for the three potentiometer leads and another for the two power leads. These connectors match male versions on the extension cable for LD linear actuators. Actuator versions without feedback have a 36″ (90 cm) cable with two unterminated, stripped power leads as shown in the right picture below. Linear actuators without feedback do not have cables that are compatible with the linear actuator extension cable.

|

|

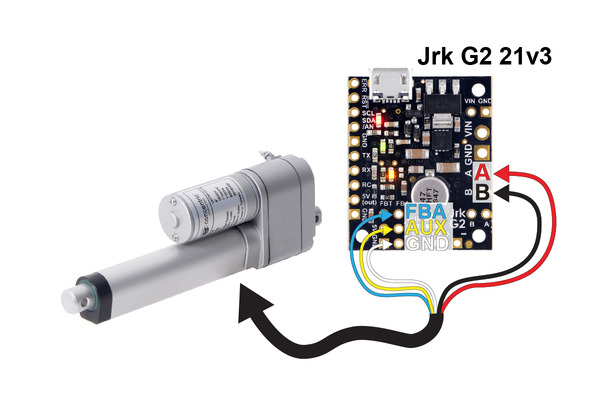

Using a Jrk G2 motor controller with a linear actuator with feedback

|

Connecting a light-duty linear actuator with feedback to a Jrk 21v3 motor controller. |

|---|

The feedback features of our Jrk G2 Motor Controllers make them a great solution for precisely controlling our linear actuators with feedback. In particular, we recommend the Jrk G2 21v3, which is also available with connectors soldered, or the more powerful Jrk G2 24v13 for applications with loads close to the upper limits of what the actuator is rated for. Our settings file for the Jrk G2 configuration utility makes setup easy, eliminating the need to tune the PID constants. To get started, follow the steps below:

- If you have not already, read through the Jrk G2 Motor Controllers User’s Guide and download its drivers and configuration software.

- Before connecting power and your actuator to your Jrk, confirm that it is working by connecting your Jrk to a PC with a USB cable and launch the configuration utility. The red LED should be on, and the green LED should be flickering quickly.

- Download the appropriate settings file for your linear actuator:

- for GF23 versions in 2, 4, or 6 inch lengths: Jrk 21v3 setting file for use with 2, 4, or 6 inch GF23-1205xx-3-65 (2k txt)

- for GF23 versions in 8, 10, or 12 inch lengths: Jrk 21v3 setting file for use with 8, 10, or 12 inch GF23-1205xx-3-65 (2k txt)

- for LACT versions with the 5:1 gear ratio: Jrk 21v3 settings file for use with LACTxP-12V-5 (2k txt)

- for LACT versions with 10:1 or 20:1 gear ratios: Jrk 21v3 settings file for use with LACTxP-12V-10 or LACTxP-12V-20 (2k txt)

Note: These same settings files will work also with the Jrk G2 24v13 if you open them with a text editor and change the “product” field near the top from “21v3” to “24v13”.

- In the configuration utility, choose File → Open settings file (Ctrl + O), and navigate to the location of the settings file you downloaded in step 3.

- Click on the PID tab of the configuration utility and verify that the proportional and derivative coefficients are not zero. If they are zero, the settings file was probably not loaded properly and you should try performing the previous step again.

- Click “Apply settings”.

- With your power supply off and USB disconnected, connect your linear actuator to your Jrk using the connections shown in the picture above.

- Turn on power, plug in USB, and reconnect to the configuration utility (use the “Connected to” drop down box if the configuration utility doesn’t automatically reconnect to your Jrk).

- On the Status tab, move the slider around to change the target position and get your actuator to move the target position.

- The settings in these files should work fairly well with any length Glideforce light-duty actuator that has a feedback potentiometer (model LACTxP-12V). However, to ensure you can control your actuator across its full stroke, you should recalibrate the feedback. Instructions for doing this can be found in the analog feedback section of the Jrk G2 User’s Guide.

Other Glideforce linear actuator options

|

Glide force ID, MD, and LD linear actuators with 6″ strokes next to their corresponding aluminum and steel mounting brackets. |

|---|

We carry a variety of Glideforce linear actuators, from the light-duty LD series through the industrial-duty ID series. The table below shows our full offering of these linear actuators:

People often buy this product together with:

|

Jrk 21v3 USB Motor Controller with Feedback |

|

Jrk 21v3 USB Motor Controller with Feedback (Connectors Soldered) |

|

Mounting Bracket for Glideforce Light-Duty Linear Actuators - Aluminum |