Pololu Blog »

Pololu Blog (Page 22)

Welcome to the Pololu Blog, where we provide updates about what we and our customers are doing and thinking about. This blog used to be Pololu president Jan Malášek’s Engage Your Brain blog; you can view just those posts here.

Popular tags: community projects new products raspberry pi arduino more…

Now available: VL53L1X library for Arduino

We’ve released a basic VL53L1X library for Arduino to make it easier to get started using an ST VL53L1X time-of-flight distance sensor with an Arduino-compatible controller.

Because of how complex the VL53L1X is and how difficult it is to learn how it works, developing a library for it has been more of a challenge than writing one for a typical sensor like an LSM303 accelerometer/magnetometer. Continued…

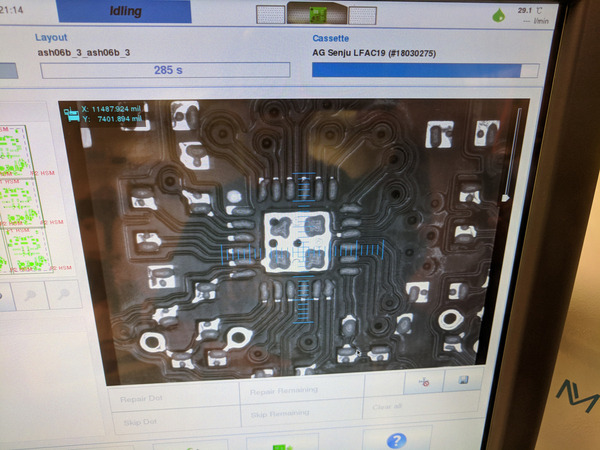

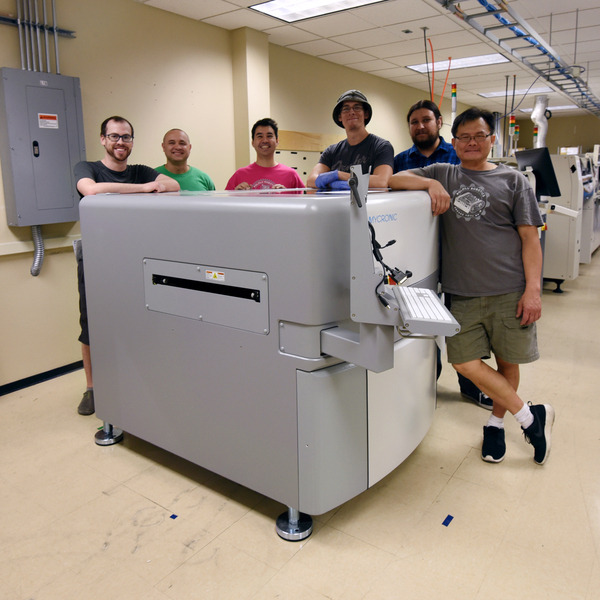

Mycronic MY600 solder paste jet printer first print

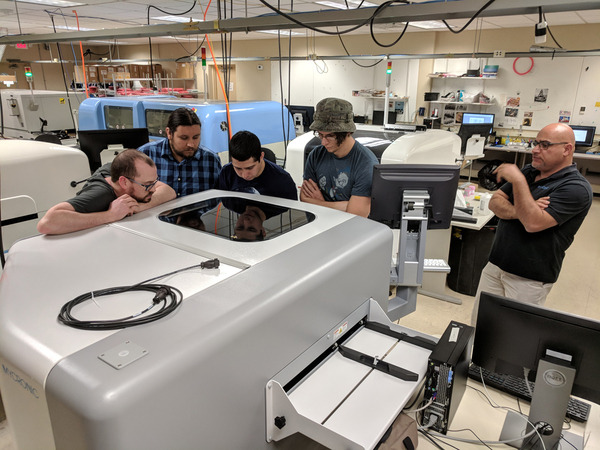

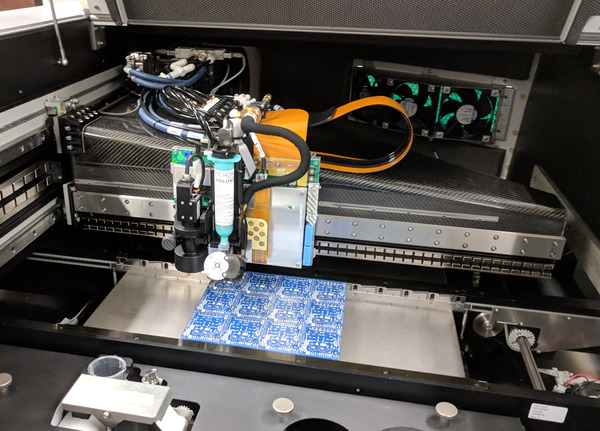

Installation of our new Mycronic MY600 that arrived earlier this month is going smoothly. Here are a few pictures and a video from our first test print on a Pololu PCB panel.

|

Ninoos from Mycronic showing us how to use the MY600 solder paste jet printer. |

|---|

|

First Pololu test panel in our new Mycronic MY600 solder paste jet printer. |

|---|

|

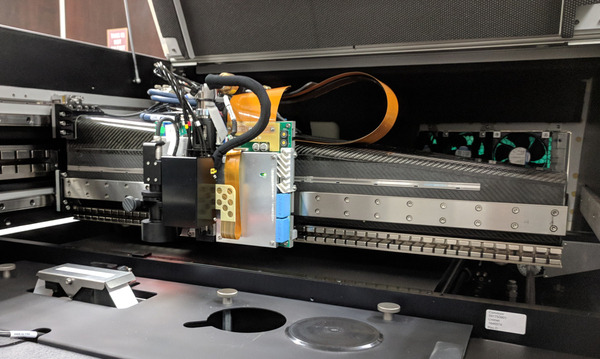

The gantry is supported only on the left side! |

|---|

|

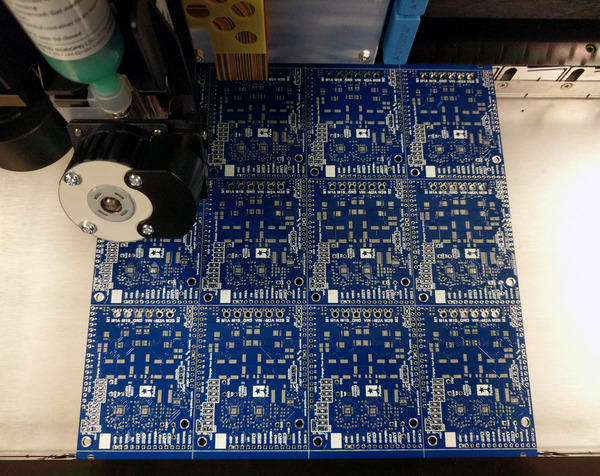

First print on a Pololu PCB panel using Mycronic MY600 solder paste jet printer. |

|---|

|

MY600 jet printer first print: Looks like we need a little more solder paste under the central chip and a little less on the leads. |

|---|

That footage of the jet printer in action is not sped up!

Save on all active Pololu-brand products, now through Tuesday

Over the next few days, we’re welcoming summer by discounting all active Pololu-brand products, which is almost everything we make. If you’re about to have a lot of free time on your hands, why not spend some of it building a robot? And if you’re going to be as busy as ever this summer, why not unwind by building a robot?

Check out the sale page for details!

Please note that we will be closed on Monday for Memorial Day, so orders will not ship until Tuesday, May 29.

MY600 solder paste jet printer arrived!

In my February post about our new equipment, I wrote about why I did not get a jet printer for solder paste. Well, I ended up getting one after all, and it arrived today.

We have a great building, but we don’t have loading docks, which always makes these big equipment deliveries a bit more of an adventure. Despite assurances that the crate would be at the back of the truck (and that it would have a lift gate that could handle the weight), it arrived way at the front.

|

18 May 2018: yet another heavy machine (MY600 jet printer) arrives deep in a truck. |

|---|

At least it wasn’t as big of a crate in as deep of a truck as this time. The Mycronic MY600 jet printer is not the biggest machine, but it weighs a ton because of its granite base. And by “it weighs a ton”, I mean literally more than two tons. Especially with the weight of the crate and the other accessories in there, it was way too much for the lift gate. We tried to get two pallet trucks under it but could not get it to move, even after repositioning the truck to make the crate moving downhill.

|

Because of the crate’s weight and weight distribution, we couldn’t drag it downhill even with two pallet trucks. |

|---|

The big forklift we rented had not arrived yet, but our smaller forklift was able to add enough pulling power to get the crate to the back of the truck.

|

Dragging the MY600 jet printer crate out of the truck with our smaller forklift. |

|---|

|

MY600 jet printer crate almost to the back of the truck. |

|---|

I like noticing that silver Honda in the back of some of these pictures. Here it is almost sixteen years ago (more about our first ten years in Vegas here):

|

Leaving Watertown, MA on 30 May 2002. |

|---|

The big forklift arrived just in time to keep us from attempting some small forklift plus lift gate kind of stunt.

|

10,000 pound forklift with long forks arrived just in time. |

|---|

The crate had a very lopsided weight distribution, and the crate had some peculiar skids that required some precision alignment to get the fork into the pocket. (The small gap was too small for the pallet trucks, which contributed to the earlier difficulty in moving the crate with pallet trucks.)

|

Couldn’t they have given us a few more inches for the fork to fit? |

|---|

|

Ryan lining up the forks just right to get under the MY600 jet printer crate. |

|---|

I really liked truck driver Sharrieff, with a great “we’re going to work together and we’re going to get this crate down” attitude. I just noticed now as I wrote this up that he’s the owner of his trucking company.

|

Woo, the crate is safely on the ground! |

|---|

With the crate in our warehouse and the sides removed, it was easier to see why the weight distribution was so off-center.

|

First glimpse of the MY600 jet printer in its crate. |

|---|

|

MY600 jet printer unwrapped. |

|---|

And here it is in its temporary home next to the Europlacer stencil printer we got earlier this year:

|

Mycronic MY600 jet printer temporarily in position next to Europlacer stencil printer. |

|---|

|

It’s a temporary home since we will be doing some major remodeling of our building later this year. At the moment we have two full SMT assembly lines, with the newest pick-and-place machine separately on its own in a batch setup. Once we free up more space on the main manufacturing floor, we should be putting the jet printer in line with the pick and place machine in a third complete line that should be ultra-optimized for efficient manufacturing in small quantities. Installation of the new jet printer isn’t until after Memorial Day, and I will be sure to post more updates once we have the machine in action.

|

We didn’t drop it! |

|---|

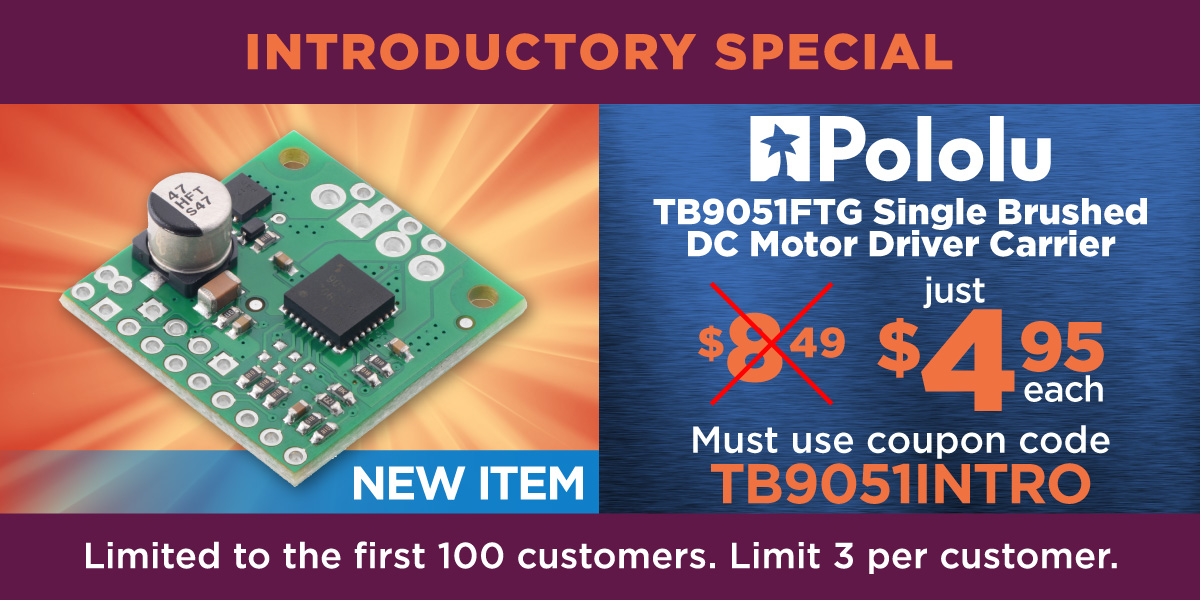

New Product: TB9051FTG Motor Driver Carrier

This is the second new motor driver product in less than a week, and I’m really excited about this one: the TB9051FTG from Toshiba. The TB67H420FTG I posted about the other day has this new part beat for higher voltages, but its one shortcoming for our purposes is that it doesn’t work at lower voltages. This new TB9051 doesn’t go up into those voltages where it starts getting dangerous, but it covers a great operating range of 4.5 V to 28 V, with transient operation to 40 V, which means you can use this driver with everything from 6 V lead-acid batteries and 2-cell LiPo packs all the way up to 24 V systems and 6-cell LiPo packs, maybe even 7-cell packs. The operating voltage range is similar to another recent favorite of mine, Maxim’s MAX14870, but this new Toshiba part delivers almost double the current.

|

Pololu dual MC33926 motor driver (assembled) on a Raspberry Pi Model B+. |

|---|

With its excellent operating voltage range and great current ability for an integrated package, I expect the TB9051 to be an ideal all-around DC brushed motor driver for most indoor robots and other projects that do not involve moving frighteningly large objects at potentially catastrophic speeds. The chip seems positioned to compete performance-wise with my previous almost-favorite chip, the Motorola Freescale NXP MC33926. That chip would have been my favorite if it had been easier to work with Freescale, and things have only gotten worse since NXP acquired them and then got distracted by yet another merger, this time with Qualcomm, which seems to have been in limbo forever. Maybe their sales are actually doing great, and we just have a hard time with them because they are busy with bigger customers. In any case, a part with great performance is not so great overall if it’s difficult to get it, so you can expect us to be updating some of those products that use the NXP part to use the Toshiba part instead.

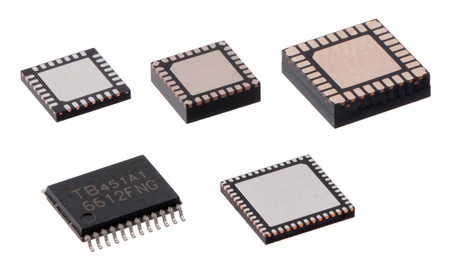

One pretty obvious feature the TB9051 has over the MC33926 is its smaller size, from 8 mm x 8 mm down to 6 mm x 6 mm, which is great for getting these onto smaller boards in smaller spaces, but it might also have some ramifications for how it tolerates pushing the limits of the specs. We liked how the MC33926 was able to endure lots of abuse from customers who were pushing it because it was our highest-voltage integrated driver. The TB9051 is, like the MC33926, an automotive-rated part, so it is intended to last a long time in harsh conditions. It’s interesting to see how thick the packages for these chips are, and I like their thickness (similar to how I like the proportions on 737 airplanes):

|

Clockwise from upper left: packages of a 28-pin microcontroller, TB9051FTG, MC33926, TB67H420FTG, and TB6612FNG. |

|---|

This video makes it seem like Toshiba is quite proud of their packaging accomplishment with the TB9051FTG:

Update: It looks like the above video might no longer be available on youtube, but it is still available on the Toshiba website.

Is the “competitor” in this video the MC33926? Sure seems like it to me. I know of no other part like that, and I keep looking.

Toshiba has not publicly posted a complete datasheet for the TB9051FTG yet, so the product page for our carrier only has a preliminary summary document. Our product page has more information about how to use the device, and we are working on getting a complete datasheet that we can post.

Since I expect this driver to hit a nice sweet spot for many of our customers’ general-purpose motor control needs, it’s a good candidate for using in some higher channel count products. We have not gone much beyond two motors (the TReX motor controllers have a third, unidirectional channel), and I would like to know what kind of interest there is in single boards that can control three or more motors. If you would like to see such products, please let me know.

As with all of our new product announcements, we are offering an introductory discount to make it extra easy to try out these new drivers. Be among the first 100 customers to use coupon code TB9051INTRO (click to add the coupon code to your cart) and get up to three units for just $4.95 each. We are still manufacturing our initial stock of these, and even if the quantity shown online goes to zero, you can backorder with the coupon price and chances are that we will be able to fill your order the same day.

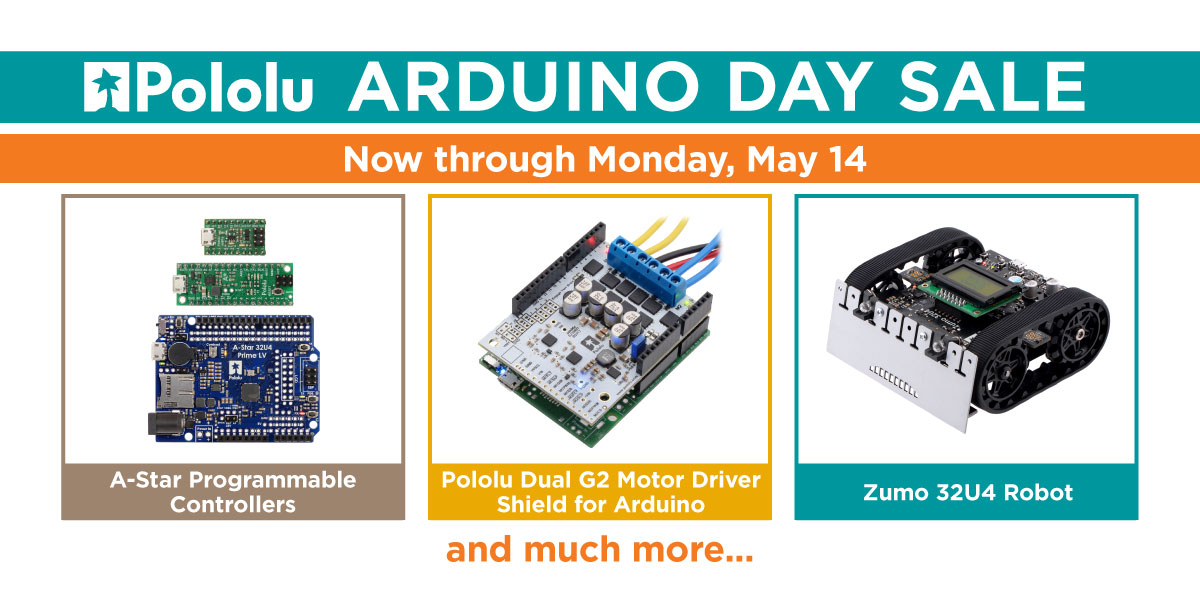

We're having an Arduino Day sale, now through Monday!

Arduino Day is this Saturday, May 12, and in celebration, we are having a big sale on many of our Arduino-related products, including Pololu-made Arduino shields and Arduino-compatible A-Stars and robots. For those who aren’t necessarily enamored with the Arduino environment but are excited about AVR microcontrollers, you can program these products from AVR Studio or other environments using our AVR Programmer, which is also on sale. And because of the awesome way we don’t include motors with the Balboa or Zumo Robot kits, we are also putting those on sale so you can get all the parts for your robots at a discount (we’ll let it slide if you just want to stock up on motors independent of any kind of Arduino application)!

The sale has already started, and it runs through Monday, May 14.

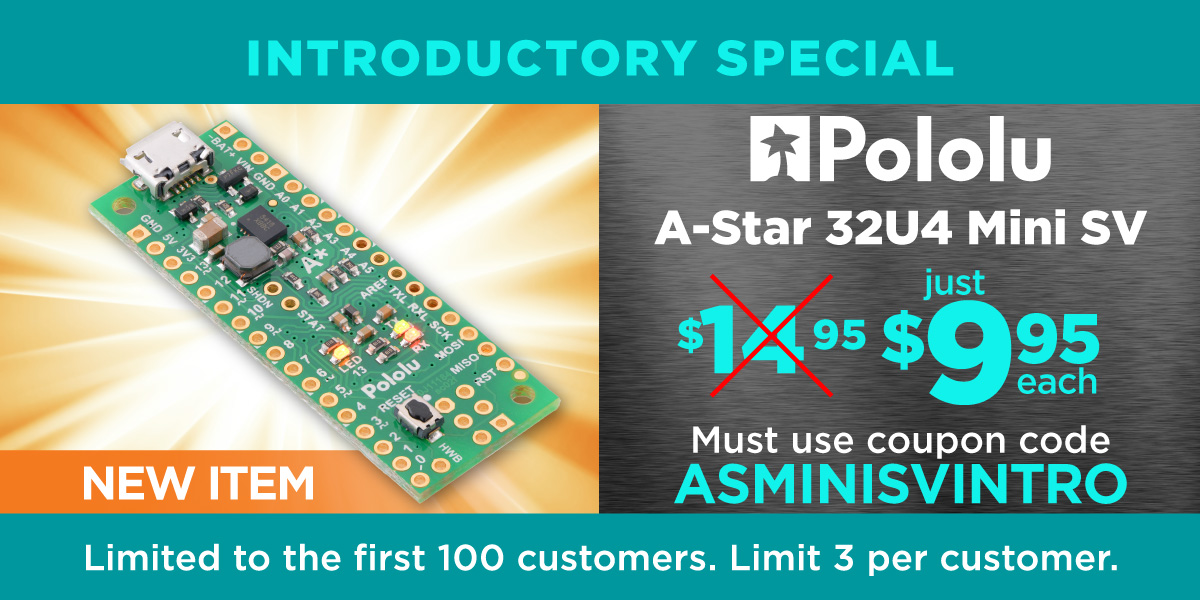

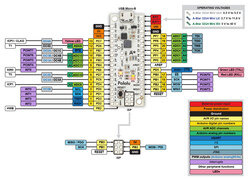

Updated product: A-Star 32U4 Mini SV

|

A-Star 32U4 Mini pinout diagram. |

|---|

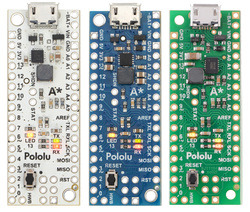

I think of our new A-Star 32U4 Mini SV as more of an update than a genuinely new product. For those of you not already familiar with our A-Star 32U4 Minis, they are a series of ATmega32U4-based, USB-programmable controllers with integrated switching regulators that offer operating voltage ranges not available on typical Arduino-compatible products; the “SV” variant features a step-down converter that enables efficient operation with inputs as high as 40 V. The slight PCB update for this latest product was done primarily for manufacturing reasons (e.g. reset button footprint change, addition of a test point, and switching to an ENIG finish that has worked better for us for double-sided assembly), but I figured that while we were updating all our internal records for the new PCB, we might as well also upgrade the regulator.

There’s a difficulty to making small improvements to products when we have hundreds of distributors around the world since even if we clear out our inventory of older versions before shipping newer units, we cannot control the inventory at distributors’ warehouses. We’re all usually tolerant of products being a little better than advertised, but when we try out a product, and then buy another one, and it ends up being worse than the one we already had, it just doesn’t feel right. (That’s one reason we sometimes do not reveal exact components we use, to avoid over-specifying some aspect of a product that we feel is not that important and that we do not want to commit to.) Once the regulator was different (and better!) enough to merit changing the product specifications, we needed to change the product number, and hence we have a new product.

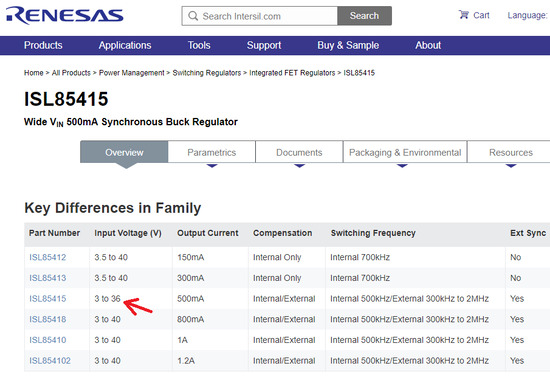

The regulator change is from the ISL85415 to the ISL85418, both made by Renesas (which acquired Intersil). The ISL85415 was the first of a great regulator family by Intersil, and they expanded the family with several pin-compatible versions with various current specifications. These new parts could also operate to 40 V instead of the 36 V of the original ISL85415, but even as various aspects of the datasheets got updated, the maximum voltage rating on the ISL85415 in particular did not.

|

Renesas website screen capture showing ISL85415 is only part in its family with 36 V maximum input. |

|---|

I asked our Intersil contact about why only the ISL85415 wasn’t rated to 40 V. It sounded like it was getting made on the same process as the other parts, and that the higher voltage rating of the later parts in the family was more the result of better characterization (and thus confidence) in the process than in any modifications to the process. In other words, new ISL85415 parts can probably do 40 V just like the other parts, and the older ISL85415 parts probably the same; they just weren’t confident about calling them 40 V parts then. But who knows what the inside story is. Maybe they did tweak their recipes a bit, and once they had parts out in the world with the 36 V spec, they didn’t want to change it without changing the part number, just like we couldn’t just keep our old A-Star part number and also talk about the higher maximum input voltage.

|

A-Star 32U4 Mini ULV, LV, and SV. |

|---|

In case you’re wondering why we didn’t just put the even better ISL85410 or ISL854102 with 1.0 A and 1.2 A outputs on the new board, it’s because the performance limit moved more to the inductor, and even if the better regulator chip takes up the same space, we would need a bigger inductor to take advantage of that. And the A-Star Minis are pretty packed designs, so there’s not much room for a bigger inductor.

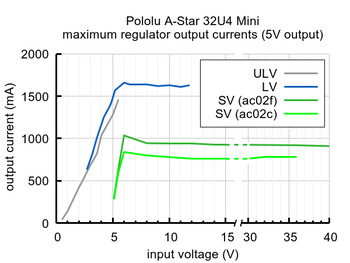

So, to make a long story short, the main new feature of the updated A-Star 32U4 Mini SV is that it can now take up to 40 V input and give you up to 800 mA to work with. This chart shows you what the new regulator (in darker green) can do compared to the older one (lighter green) on the A-Star Mini. It looks like the old one already provided well over its 500 mA specification.

|

Typical maximum output current of the regulators on the A-Star 32U4 Mini boards. |

|---|

To make this new product a little more exciting, we reassessed our costs and cut some of our margins in keeping with our push this year to be more competitive in our manufacturing. We have reduced the unit price from $19.95 to $14.95. And as usual for our new product releases this year, we’re offering an extra introductory discount: use coupon code ASMINISVINTRO to get up to three units for just $9.95. (Click to add the coupon code to your cart.) Our promotion banner shows the usual limit for the first 100 coupon uses, but since we’re also having our Arduino Day sale, we’re removing that restriction for the duration of the sale. If we run out of stock during the sale, you can still backorder with the discount, and we should be able to catch up with production within a few days.

New product: TB67H420FTG Dual/Single Motor Driver Carrier

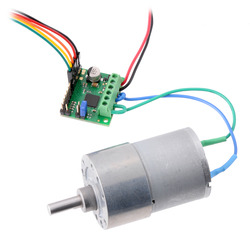

Hey! We have a new dual motor driver carrier for Toshiba’s exciting TB67H420FTG that offers quite the power jump from the TB6612FNG we popularized over a decade ago. This chip has a recommended operating range of 10-47 V and can deliver peaks of 4.5 A per channel. In our tests on this carrier, without additional heat sinking or airflow, the maximum continuous current is about 1.7 A per channel.

|

TB67H420FTG Dual/Single Motor Driver Carrier driving a motor in single-channel mode. |

|---|

One of the most common questions we get about our motor drivers is whether the outputs can be paralleled to drive a single bigger motor. The TB67H420FTG specifically has that feature built-in so that you can safely do that while only requiring control signal connections for one channel. This brings the available current for single-motor operation to 9 A peak and about 3.4 A continuous.

The TB67H420FTG has a maximum supply voltage of 50 V, making it one of the highest-voltage drivers we have available. Please note that we populated with 50 V capacitors on the supply line, so there is less margin there than on our usual products if you want to push the upper voltage limits of this chip. As with most of our carriers, we also added reverse voltage protection. The MOSFET we use for that is a 40 V max MOSFET, so the maximum reverse voltage that it protects you from is that same 40 V. If you’re wondering why we didn’t use higher-voltage parts, it’s because the next standard voltages are much higher, 100 V in the case of the capacitors. Getting the same capacitance at that rating would require bulkier, more expensive capacitors for almost no benefit. I’m telling you here in case you are one of those people who like to put 55 V on a 50 V max part just to see what will happen.

|

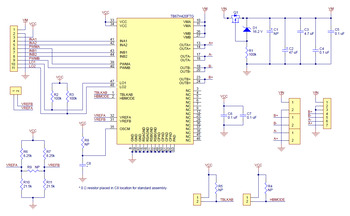

Schematic diagram of the TB67H420FTG Dual/Single Motor Driver Carrier. |

|---|

Be among the first 100 customers to use coupon code TB67H420INTRO (click to add the coupon code to your cart) and get up to three units at the introductory special price of $5.95 each. The first batches are just coming out of production, so even if the available stock goes to zero, you can still backorder with the coupon price and chances are that we will be able to fill your order the same day.

Video: How to Install Terminal Blocks

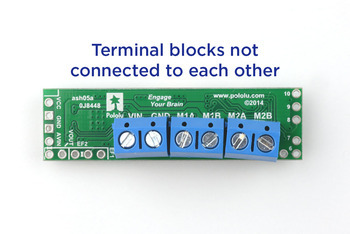

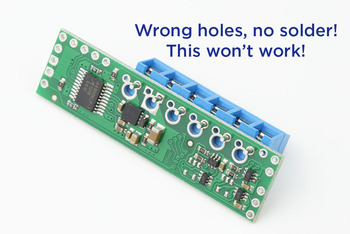

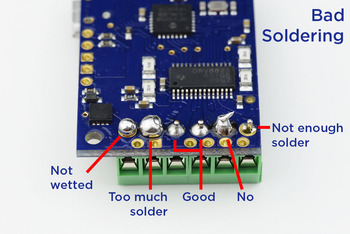

On Monday, after receiving a photo of some wonky-looking terminal blocks, our tech support team mentioned to me that we get a good amount of photos from customers needing help with their products that have their terminal blocks installed incorrectly. They either aren’t stacked together properly, are inserted into the wrong holes on the boards, or they’re soldered incorrectly. I tried to make some recreations of the problems we see most often so you can see what I’m talking about:

|

|

|

So at the request of our support team, I made this video that goes over how terminal blocks should be installed:

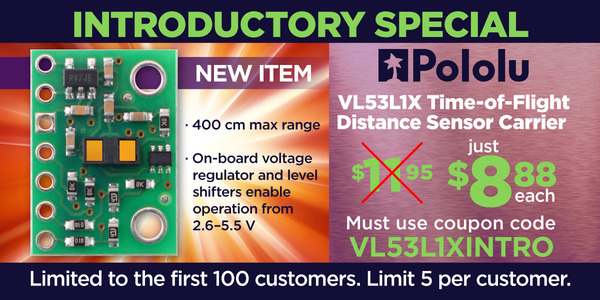

New product: VL53L1X Time-of-Flight Distance Sensor Carrier

The carrier board for the VL53L1X that many of us have been waiting for is finally here! The VL53L1X is ST’s newest time-of-flight (ToF) range finder for which we first saw announcements over a year ago, but they were not available to us for ordering until earlier this year. The part is pin-compatible with the earlier VL53L0X, so we were able to put them on the same PCB as we use for that carrier as soon as our first reel of new sensors came in.

Be among the first 100 customers to use coupon code VL53L1XINTRO (click to add the coupon code to your cart) and get up to five units at the introductory special price of $8.88 each. We have a few hundred made to begin with, and we are continuing to make more, so even if the available stock goes to zero, you can still backorder with the coupon price and chances are that we will be able to fill your order the same day.