Pololu Blog »

Posts tagged “motors”

You are currently viewing a selection of posts from the Pololu Blog. You can also view all the posts.

Popular tags: community projects new products raspberry pi arduino more…

New products: Micro Metal Gearmotors with integrated encoders

|

|

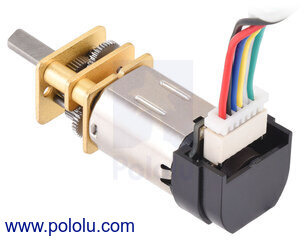

Our Micro Metal Gearmotors are now available with integrated quadrature encoders! These are the same top-entry and side-entry encoders that were previously only available separately, and now you can get them preassembled on the gearmotors and covered by a snap-on plastic cap. On the assembled units, the two available styles are denoted as “Back Connector”, which has the connector oriented parallel to the motor, and “Side Connector”, which is perpendicular to the motor. These connectors work with our assortment of female 6-pin JST SH-style cables and 6-pin JST SH-style connector boards.

|

|

For detailed dimensions, specifications, and usage information, see the Micro Metal Gearmotor datasheet (5MB pdf).

With 65 different combinations of gearboxes and motors each now available with two encoder styles, that makes 130 new products in all, and it increases our total Micro Metal Gearmotor selection to 260 versions. We are still working on getting everything stocked up, but we manufacture these in house, so we can make some of any particular version quickly. If there is a version you want that is currently out of stock, you can backorder it and we should be able to make and ship it in a few days. (Please note that we are currently not stocking the 5:1 versions with encoders but we are able to make them by special request; please contact us if you are interested in placing a special order for those.) Here is a full list of all the available options now:

| Rated Voltage |

Stall Current |

No-Load Current |

No-Load Speed (RPM) |

Extrapolated Stall Torque |

Max Power (W) |

Approx Gear Ratio |

No Encoder |

w/ Extended Motor Shaft |

w/ Encoder, Back Conn. |

w/ Encoder, Side Conn. |

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| (kg⋅cm) | (oz⋅in) | ||||||||||

| HPCB 12V (high-power, carbon brushes) |

|||||||||||

| 12 V | 0.75 A | 100 mA | 6800 | 0.09 | 1.3 | – | 5:1 | #3036 | #3047 | #5204 | #5205 |

| 80 mA | 3400 | 0.17 | 2.4 | 1.5 | 10:1 | #3037 | #3048 | #5206 | #5207 | ||

| 2200 | 0.25 | 3.5 | 1.4 | 15:1 | #4788 | #4789 | #5208 | #5209 | |||

| 1100 | 0.39 | 5.4 | 1.1 | 30:1 | #3038 | #3049 | #5210 | #5211 | |||

| 650 | 0.67 | 9.3 | 1.1 | 50:1 | #3039 | #3050 | #5212 | #5213 | |||

| 450 | 1.0 | 14 | 1.1 | 75:1 | #3040 | #3051 | #5214 | #5215 | |||

| 330 | 1.3 | 18 | 1.1 | 100:1 | #3041 | #3052 | #5216 | #5217 | |||

| 220 | 1.8 | 25 | 1.0 | 150:1 | #3042 | #3053 | #5218 | #5219 | |||

| 160 | 2.5 | 35 | 1.0 | 210:1 | #3043 | #3054 | #5220 | #5221 | |||

| 130 | 3.0 | 42 | 1.1 | 250:1 | #3044 | #3055 | #5222 | #5223 | |||

| 110 | 3.3 | 46 | 1.0 | 298:1 | #3045 | #3056 | #5224 | #5225 | |||

| 85 | 5.0 | 69 | 1.1 | 380:1 | #4798 | #4799 | #5226 | #5227 | |||

| 35 | 10 | 140 | – | 1000:1 | #3046 | #3057 | #5228 | #5229 | |||

| Rated Voltage |

Stall Current |

No-Load Current |

No-Load Speed (RPM) |

Extrapolated Stall Torque |

Max Power (W) |

Approx Gear Ratio |

No Encoder | w/ Extended Motor Shaft |

w/ Encoder, Back Conn. |

w/ Encoder, Side Conn. |

|

| (kg⋅cm) | (oz⋅in) | ||||||||||

| HPCB 6V (high-power, carbon brushes) |

|||||||||||

| 6 V | 1.5 A | 170 mA | 6500 | 0.09 | 1.3 | – | 5:1 | #3060 | #3082 | #5178 | #5179 |

| 150 mA | 3300 | 0.17 | 2.4 | 1.3 | 10:1 | #3061 | #3071 | #5180 | #5181 | ||

| 2100 | 0.25 | 3.5 | 1.3 | 15:1 | #4786 | #4787 | #5182 | #5183 | |||

| 1100 | 0.45 | 6.2 | 1.2 | 30:1 | #3062 | #3072 | #5184 | #5185 | |||

| 650 | 0.74 | 10 | 1.2 | 50:1 | #3063 | #3073 | #5186 | #5187 | |||

| 430 | 1.1 | 15 | 1.3 | 75:1 | #3064 | #3074 | #5188 | #5189 | |||

| 330 | 1.6 | 22 | 1.3 | 100:1 | #3065 | #3075 | #5190 | #5191 | |||

| 220 | 2.0 | 28 | 1.1 | 150:1 | #3066 | #3076 | #5192 | #5193 | |||

| 160 | 2.8 | 39 | 1.1 | 210:1 | #3067 | #3077 | #5194 | #5195 | |||

| 130 | 3.2 | 44 | 1.1 | 250:1 | #3068 | #3078 | #5196 | #5197 | |||

| 110 | 3.4 | 47 | 1.0 | 298:1 | #3069 | #3079 | #5198 | #5199 | |||

| 85 | 5.0 | 69 | 1.1 | 380:1 | #4796 | #4797 | #5200 | #5201 | |||

| 33 | 11 | 150 | – | 1000:1 | #3070 | #3080 | #5202 | #5203 | |||

| Rated Voltage |

Stall Current |

No-Load Current |

No-Load Speed (RPM) |

Extrapolated Stall Torque |

Max Power (W) |

Approx Gear Ratio |

No Encoder | w/ Extended Motor Shaft |

w/ Encoder, Back Conn. |

w/ Encoder, Side Conn. |

|

| (kg⋅cm) | (oz⋅in) | ||||||||||

| HP 6V (high-power) |

|||||||||||

| 6 V | 1.6 A | 120 mA | 6100 | 0.11 | 1.5 | – | 5:1 | #1000 | #2210 | #5152 | #5153 |

| 100 mA | 3100 | 0.22 | 3.0 | 1.6 | 10:1 | #999 | #2211 | #5154 | #5155 | ||

| 2000 | 0.30 | 4.2 | 1.5 | 15:1 | #4784 | #4785 | #5156 | #5157 | |||

| 1000 | 0.57 | 7.9 | 1.5 | 30:1 | #1093 | #2212 | #5158 | #5159 | |||

| 590 | 0.86 | 12 | 1.3 | 50:1 | #998 | #2213 | #5160 | #5161 | |||

| 410 | 1.3 | 18 | 1.4 | 75:1 | #2361 | #2215 | #5162 | #5163 | |||

| 310 | 1.7 | 24 | 1.3 | 100:1 | #1101 | #2214 | #5164 | #5165 | |||

| 210 | 2.4 | 33 | 1.2 | 150:1 | #997 | #2386 | #5166 | #5167 | |||

| 150 | 3.0 | 42 | 1.1 | 210:1 | #996 | #2216 | #5168 | #5169 | |||

| 120 | 3.4 | 47 | 1.1 | 250:1 | #995 | #2217 | #5170 | #5171 | |||

| 100 | 4.0 | 56 | 1.1 | 298:1 | #994 | #2218 | #5172 | #5173 | |||

| 84 | 5.5 | 76 | 1.1 | 380:1 | #4794 | #4795 | #5174 | #5175 | |||

| 31 | 12 | 170 | – | 1000:1 | #1595 | #2373 | #5176 | #5177 | |||

| Rated Voltage |

Stall Current |

No-Load Current |

No-Load Speed (RPM) |

Extrapolated Stall Torque |

Max Power (W) |

Approx Gear Ratio |

No Encoder | w/ Extended Motor Shaft |

w/ Encoder, Back Conn. |

w/ Encoder, Side Conn. |

|

| (kg⋅cm) | (oz⋅in) | ||||||||||

| MP 6V (medium-power) |

|||||||||||

| 6 V | 0.67 A | 80 mA | 4400 | 0.06 | 0.8 | – | 5:1 | #2362 | #2376 | #5126 | #5127 |

| 70 mA | 2200 | 0.11 | 1.5 | – | 10:1 | #2363 | #2377 | #5128 | #5129 | ||

| 1400 | 0.20 | 2.8 | 0.70 | 15:1 | #4782 | #4783 | #5130 | #5131 | |||

| 720 | 0.33 | 4.6 | 0.57 | 30:1 | #2364 | #2378 | #5132 | #5133 | |||

| 420 | 0.54 | 7.5 | 0.55 | 50:1 | #2365 | #2379 | #5134 | #5135 | |||

| 290 | 0.78 | 11 | 0.54 | 75:1 | #2366 | #2380 | #5136 | #5137 | |||

| 220 | 0.94 | 13 | 0.50 | 100:1 | #2367 | #2381 | #5138 | #5139 | |||

| 150 | 1.3 | 18 | 0.48 | 150:1 | #2368 | #2382 | #5140 | #5141 | |||

| 100 | 1.7 | 24 | 0.46 | 210:1 | #2369 | #2383 | #5142 | #5143 | |||

| 88 | 2.2 | 31 | 0.48 | 250:1 | #2370 | #2384 | #5144 | #5145 | |||

| 73 | 2.4 | 33 | 0.44 | 298:1 | #2371 | #2385 | #5146 | #5147 | |||

| 57 | 3.6 | 50 | 0.53 | 380:1 | #4792 | #4793 | #5148 | #5149 | |||

| 22 | 6.7 | 93 | – | 1000:1 | #2372 | #3059 | #5150 | #5151 | |||

| Rated Voltage |

Stall Current |

No-Load Current |

No-Load Speed (RPM) |

Extrapolated Stall Torque |

Max Power (W) |

Approx Gear Ratio |

No Encoder | w/ Extended Motor Shaft |

w/ Encoder, Back Conn. |

w/ Encoder, Side Conn. |

|

| (kg⋅cm) | (oz⋅in) | ||||||||||

| LP 6V (low-power) |

|||||||||||

| 6 V | 0.36 A | 50 mA | 2500 | 0.05 | 0.7 | – | 5:1 | #1100 | #2200 | #5100 | #5101 |

| 40 mA | 1300 | 0.10 | 1.4 | – | 10:1 | #1099 | #2201 | #5102 | #5103 | ||

| 860 | 0.17 | 2.4 | 0.37 | 15:1 | #4780 | #4781 | #5104 | #5105 | |||

| 450 | 0.29 | 4.0 | 0.31 | 30:1 | #993 | #2202 | #5106 | #5107 | |||

| 270 | 0.44 | 6.1 | 0.29 | 50:1 | #1098 | #2203 | #5108 | #5109 | |||

| 180 | 0.64 | 8.9 | 0.29 | 75:1 | #2360 | #2209 | #5110 | #5111 | |||

| 130 | 0.74 | 10 | 0.25 | 100:1 | #992 | #2204 | #5112 | #5113 | |||

| 90 | 1.1 | 15 | 0.25 | 150:1 | #1097 | #2205 | #5114 | #5115 | |||

| 65 | 1.6 | 22 | 0.25 | 210:1 | #1096 | #2206 | #5116 | #5117 | |||

| 54 | 1.7 | 24 | 0.23 | 250:1 | #1095 | #2207 | #5118 | #5119 | |||

| 45 | 2.0 | 28 | 0.22 | 298:1 | #1094 | #2208 | #5120 | #5121 | |||

| 36 | 2.9 | 40 | 0.27 | 380:1 | #4790 | #4791 | #5122 | #5123 | |||

| 13 | 5.5 | 76 | – | 1000:1 | #1596 | #3058 | #5124 | #5125 | |||

Note: Stalling or overloading gearmotors can greatly decrease their lifetimes and even result in immediate damage. The recommended upper limit for instantaneous torque is 2.5 kg⋅cm (35 oz⋅in) for the 380:1 and 1000:1 gearboxes, and 2 kg⋅cm (25 oz⋅in) for all the other gear ratios; we strongly advise keeping applied loads well under this limit. Stalls can also result in rapid (potentially on the order of seconds) thermal damage to the motor windings and brushes, especially for the versions that use high-power (HP and HPCB) motors; a general recommendation for brushed DC motor operation is 25% or less of the stall current.

Performance graphs for our 25D Metal Gearmotors

|

|

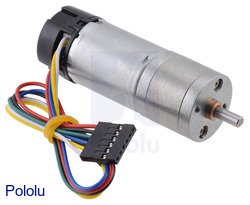

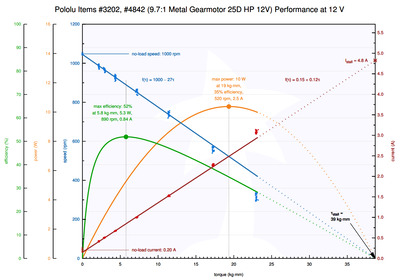

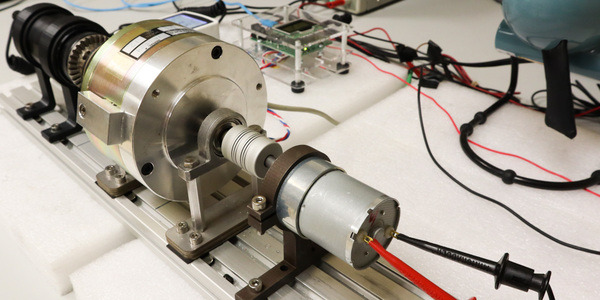

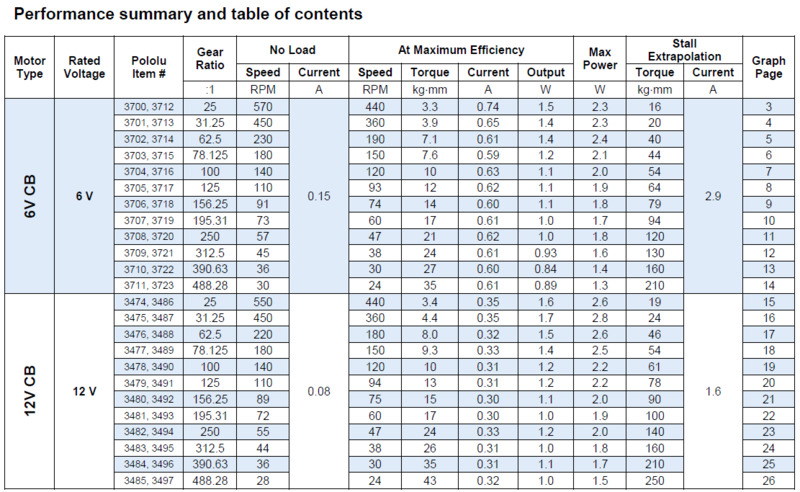

We have published performance graphs (2MB pdf) for our 25D Metal Gearmotors! Each chart is based on hundreds of individual measurements that reveal how the speed, current, power, and efficiency of that particular gearmotor version depend on the applied load (i.e. torque). Our test methodology is the same as the one we used to make our Micro Metal Gearmotor performance graphs, so you can see our blog post about that for more information.

|

25D mm metal gearmotor undergoing dynamic performance testing. |

|---|

These characterizations are yet another way we set our gearmotors apart from the many similar-looking alternatives out there. When you get your gearmotors from us, you know what kind of performance to expect, and you can count on consistency from batch to batch.

If you have any questions or feedback about these graphs or if there is additional information you would like to see available for our motors, please feel free to contact us (or just leave a comment below).

|

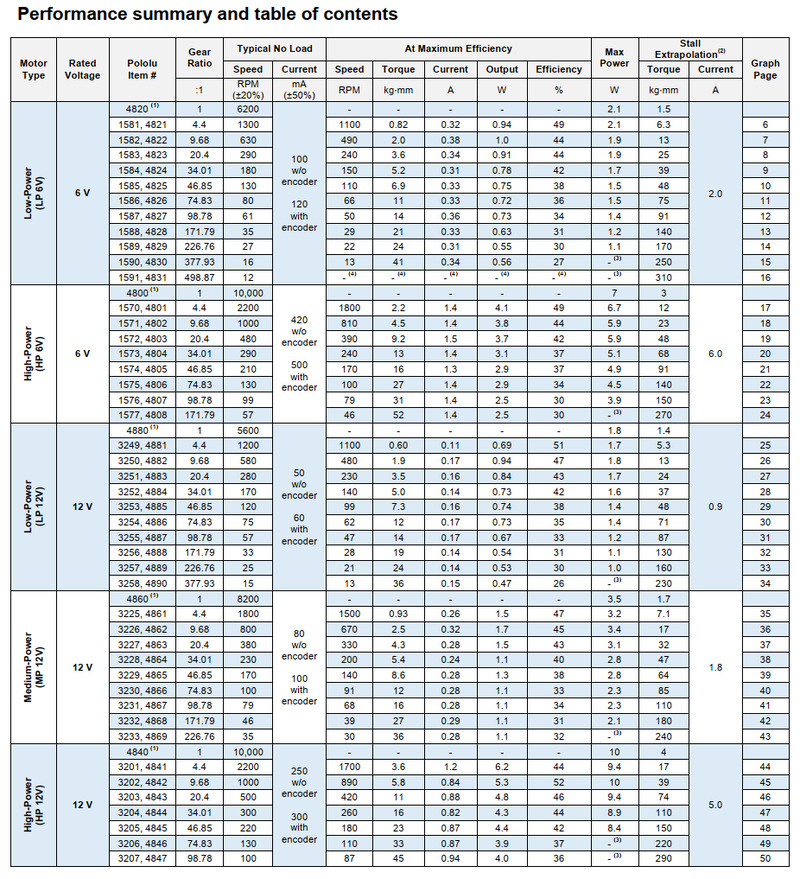

Performance summary table from 25D mm Metal Geamotor datasheet. |

|---|

New products: 24V 37D Metal Gearmotors

|

We are excited to share that we have expanded our line of 37D Metal Gearmotors to include 24 V options. These brushed DC gearmotors are the largest and most powerful we carry, measuring 37 mm (1.46″) in diameter. They are available in gear ratios ranging from 6.3:1 to 150:1 and with or without integrated 64 CPR quadrature encoders on the motor shafts. The 12 V and 24 V motors offer approximately the same performance at their respective nominal voltages, with the 24 V motor drawing half the current of the 12 V motor. The table below summarizes all of the options we now have available. Please see our newest revision of the 37D metal gearmotor datasheet (2MB pdf) for the full specifications and performance graphs for all the options.

| Rated Voltage |

Stall Current |

No-Load Current |

Gear Ratio | No-Load Speed (RPM) |

Extrapolated Stall Torque |

Max Power (W) |

Without Encoder |

With Encoder |

|

|---|---|---|---|---|---|---|---|---|---|

| (kg ⋅ cm) | (oz ⋅ in) | ||||||||

| 12 V | 5.5 A | 0.2 A | 1:1 (no gearbox) | 10,000 | 0.5 | 7 | – | – | item #4750 |

| 6.3:1 | 1600 | 3.0 | 42 | 12 | item #4747 | item #4757 | |||

| 10:1 | 1000 | 4.9 | 68 | 12 | item #4748 | item #4758 | |||

| 19:1 | 530 | 8.5 | 120 | 12 | item #4741 | item #4751 | |||

| 30:1 | 330 | 14 | 190 | 12 | item #4742 | item #4752 | |||

| 50:1 | 200 | 21 | 290 | 10 | item #4743 | item #4753 | |||

| 70:1 | 150 | 27 | 380 | 10* | item #4744 | item #4754 | |||

| 100:1 | 100 | 34 | 470 | 8* | item #4745 | item #4755 | |||

| 131:1 | 76 | 45 | 630 | 6* | item #4746 | item #4756 | |||

| 150:1 | 67 | 49 | 680 | 6* | item #2829 | item #2828 | |||

| 24 V | 3 A | 0.1 A | 1:1 (no gearbox) | 10,000 | 0.55 | 8 | – | – | item #4690 |

| 6.3:1 | 1600 | 3.5 | 49 | 14 | item #4688 | item #4698 | |||

| 10:1 | 1000 | 5.5 | 76 | 14 | item #4689 | item #4699 | |||

| 19:1 | 530 | 9.5 | 130 | 13 | item #4681 | item #4691 | |||

| 30:1 | 330 | 15 | 210 | 13 | item #4682 | item #4692 | |||

| 50:1 | 200 | 23 | 320 | 12 | item #4683 | item #4693 | |||

| 70:1 | 140 | 31 | 430 | 10* | item #4684 | item #4694 | |||

| 100:1 | 100 | 39 | 540 | 8* | item #4685 | item #4695 | |||

| 131:1 | 79 | 47 | 650 | 6* | item #4686 | item #4696 | |||

| 150:1 | 68 | 56 | 780 | 6* | item #4687 | item #4697 | |||

| * Output power for these units is constrained by gearbox load limits; spec provided is output power at max recommended load of 10 kg⋅cm. | |||||||||

Note: The listed stall torques and currents are theoretical extrapolations; units will typically stall well before these points as the motors heat up. Stalling or overloading gearmotors can greatly decrease their lifetimes and even result in immediate damage. The recommended upper limit for continuously applied loads is 10 kg-cm (150 oz-in), and the recommended upper limit for instantaneous torque is 25 kg-cm (350 oz-in). Stalls can also result in rapid (potentially on the order of seconds) thermal damage to the motor windings and brushes; a general recommendation for brushed DC motor operation is 25% or less of the stall current.

37D gearmotors: helical pinion gear, new 150:1 gear ratio, and performance graphs

|

|

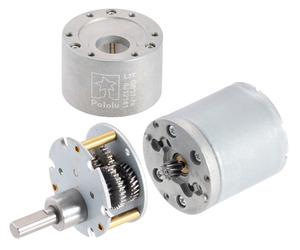

We have some big announcements related to our 37D Metal Gearmotors to share! First, we now have new versions of our 37D gearmotors that feature helical pinion gears and first mating gears as seen in the photo on the left above. The helical gears help reduce vibrations, making the gearbox a little quieter and more efficient than the original versions that used all spur gears. The performance is otherwise unchanged, and the dimensions are the same, so the new versions with helical pinion gears can be used as direct replacements for the original units. We are using new product numbers for the new versions so you can know exactly which one you are getting, and the product numbers for the original spur versions are being phased out. The following table shows all of the new helical-pinion versions:

| Rated Voltage |

Stall Current |

No-Load Current |

Gear Ratio | No-Load Speed (RPM) |

Extrapolated Stall Torque |

Max Power (W) |

Without Encoder |

With Encoder |

|

|---|---|---|---|---|---|---|---|---|---|

| (kg ⋅ cm) | (oz ⋅ in) | ||||||||

| 12 V | 5.5 A | 0.15 A | 1:1 (no gearbox) | 10,000 | 0.5 | 7 | – | – | item #4750 |

| 19:1 | 540 | 8.5 | 120 | 12 | item #4741 | item #4751 | |||

| 30:1 | 330 | 14 | 190 | 12 | item #4742 | item #4752 | |||

| 50:1 | 200 | 21 | 290 | 10 | item #4743 | item #4753 | |||

| 70:1 | 150 | 27 | 380 | 10 | item #4744 | item #4754 | |||

| 100:1 | 100 | 34 | 470 | 8 | item #4745 | item #4755 | |||

| 131:1 | 76 | 45 | 630 | 6 | item #4746 | item #4756 | |||

| 150:1 | 67 | 49 | 680 | 6 | item #2829 | item #2828 | |||

We have also expanded the 37D gearmotor line by adding a new 150:1 gear ratio, which becomes our new highest gear ratio offering for this line of gearmotors. This version has an extrapolated (i.e. theoretical) stall torque of 49 kg⋅cm (680 oz⋅in), but please keep in mind that the point of high gear ratios like this is not to allow for more total torque. Rather, they enable slower speeds and draw less current than lower gear ratios for the same loads. For all of our 37D gearmotors, we recommend keeping continuously applied loads under 10 kg⋅cm (150 oz⋅in) and instantaneous torques under 25 kg⋅cm (350 oz⋅in).

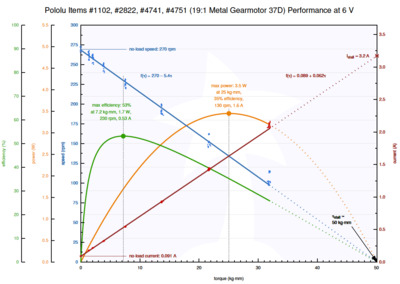

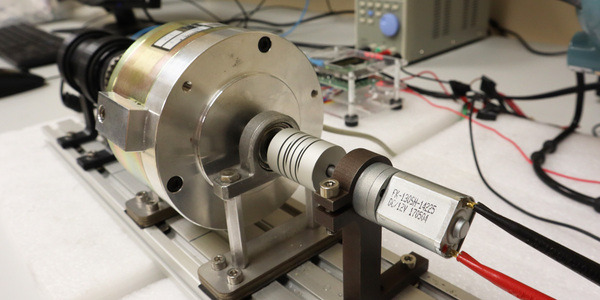

Finally, we now have published performance graphs (1MB pdf) for our 37D gearmotors, just like the ones we previously released for our Micro Metal Gearmotors and our 20D Gearmotors! Each chart is based on hundreds of individual measurements that reveal how the speed, current, power, and efficiency of that particular gearmotor version depend on the applied load (i.e. torque).

|

37D mm metal gearmotor undergoing dynamic performance testing. |

|---|

These characterizations are yet another way we set our gearmotors apart from the many similar-looking alternatives out there. When you get your gearmotors from us, you know exactly what kind of performance to expect, and because we make and test them ourselves, you can count on getting that same performance batch after batch after batch.

If you have any questions or feedback about these graphs or if there is additional information you would like to see available for our motors, please feel free to contact us (or just leave a comment below). And if you are wondering about graphs for 25D Gearmotors, don’t worry, those are coming! (If you need something before those datasheets are done, just let us know and we might be able to get you preliminary data for a particular gearmotor.)

|

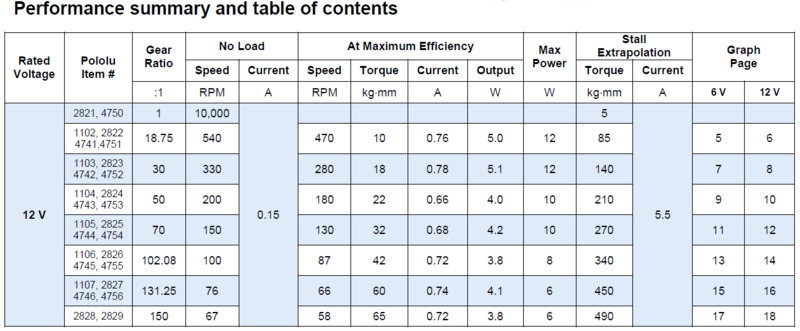

Performance summary table from 37D mm Metal Geamotor datasheet. |

|---|

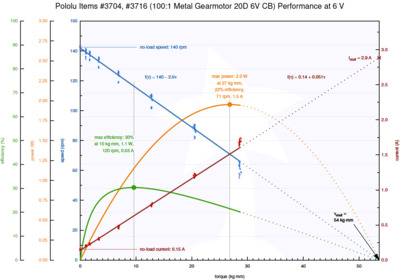

Performance graphs for our 20D Metal Gearmotors

|

|

We now have published performance graphs (1MB pdf) for our 20D Metal Gearmotors! Each chart is based on hundreds of individual measurements that reveal how the speed, current, power, and efficiency of that particular gearmotor version depend on the applied load (i.e. torque). Our test methodology is the same as the one we used to make our Micro Metal Gearmotor performance graphs, so you can see our blog post about that for more information.

|

20D mm metal gearmotor undergoing dynamic performance testing. |

|---|

These characterizations are yet another way we set our gearmotors apart from the many similar-looking alternatives out there. When you get your gearmotors from us, you know exactly what kind of performance to expect, and you can count on getting that same performance batch after batch after batch.

If you have any questions or feedback about these graphs or if there is additional information you would like to see available for our motors, please feel free to contact us (or just leave a comment below). And if you are wondering about graphs for our larger gearmotors, don’t worry, those are coming! (If you need something before those datasheets are done, just let us know and we might be able to get you preliminary data for a particular gearmotor.)

|

Performance summary table from 20D mm Metal Geamotor datasheet. |

|---|

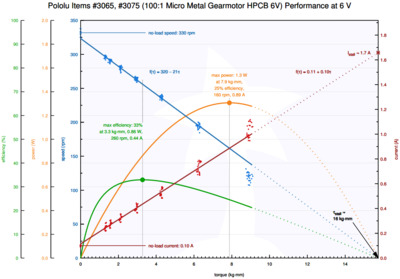

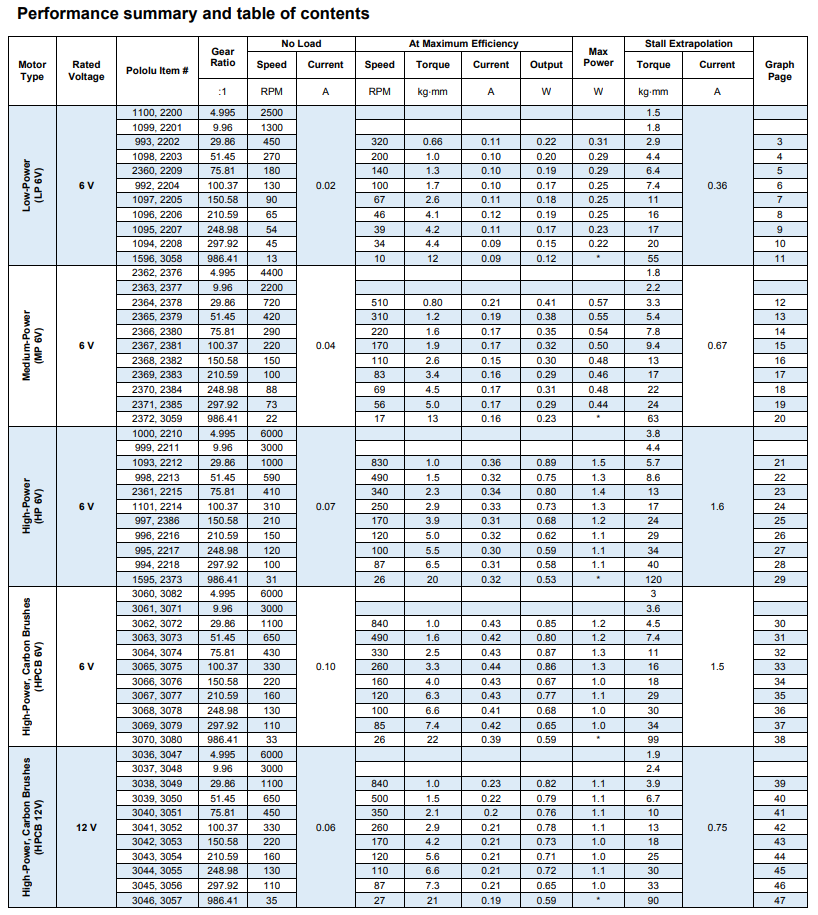

Performance graphs for our Micro Metal Gearmotors

|

|

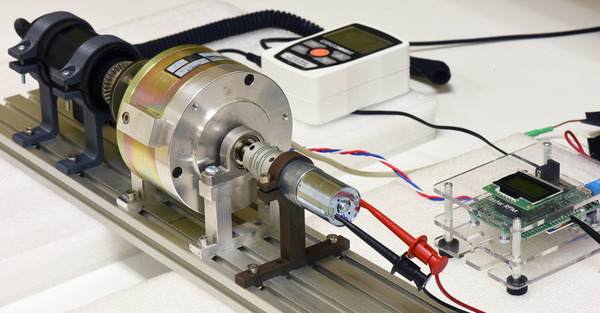

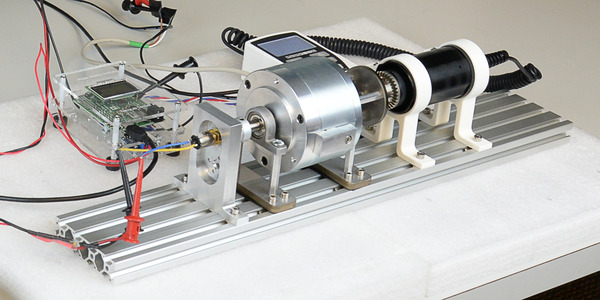

After spending many months conducting thousands of motor tests, we are excited to finally publish performance graphs for our micro metal gearmotors (5MB pdf). In some sense, this datasheet is the culmination of a decade of work to improve our processes and better characterize our gearmotors, and we have come a long way since those early tests clamping motors in vises and making them lift ever heavier bags of steel bearings. Here is one of the setups we are using now:

|

Micro Metal Gearmotor undergoing dynamic performance testing. |

|---|

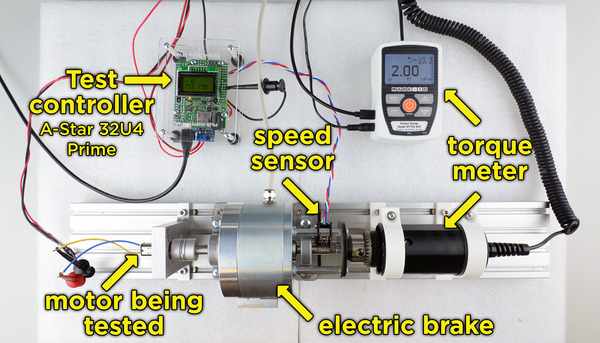

The key thing is to be able to apply a measurable, variable load while the motor is spinning, which we do via an electromagnetic brake coupled to a torque meter. A combination of programs running on an A-Star 32U4 Prime test controller and a PC automatically sweep the load through a sequence of points while measuring parameters such as speed, current, and torque (plus internal test rig currents, voltages, etc).

|

Micro Metal Gearmotor performance test setup. |

|---|

These performance characterizations are the latest example of our continued commitment to being the best source for this popular form factor of gearmotor. You might see similar-looking motors elsewhere, but no one comes close to our offering, from the quality of the gears to our exclusive long-life carbon brush options to the overall breadth of our selection (over 100 versions!), all in stock for shipment the day you order.

Please note that we are still in the process of updating the specifications on our website to match new, more accurate data from the performance graphs, so if you notice discrepancies between what is in the datasheet and what is on the product page, go with the datasheet.

If you have any questions or feedback about these graphs or if there is additional information you would like to see available for our motors, please feel free to contact us (or just leave a comment below). And if you are wondering about graphs for our larger gearmotors, don’t worry, those are coming! (If you need something before those datasheets are done, just let us know and we might be able to get you preliminary data for a particular gearmotor.)

|

Performance summary table from Micro Metal Geamotor datasheet. |

|---|