Pololu Blog » Posts tagged “new products” »

Posts tagged “new products” (Page 5)

You are currently viewing a selection of posts from the Pololu Blog. You can also view all the posts.

Popular tags: community projects new products raspberry pi arduino more…

The Zumo gets a graphical display too: new Zumo 32U4 OLED Robot!

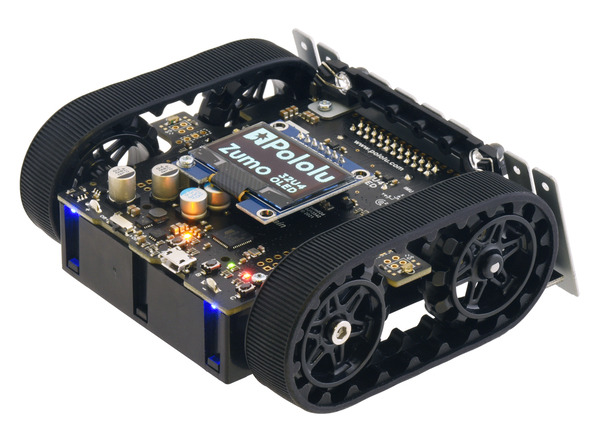

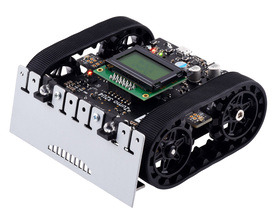

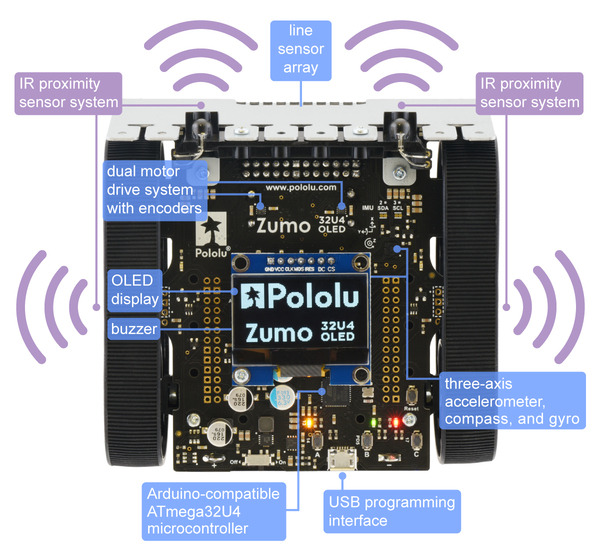

Our 3pi+ 32U4 robot got an upgraded OLED display earlier this year, and now it’s the Zumo’s turn with the release of our new Zumo 32U4 OLED Robot!

|

In many ways, this new version is just like the original Zumo 32U4: it’s a versatile tracked robot designed to be a capable Mini-Sumo competitor, but with enough sensors and extra features to enable lots of other applications. The Zumo 32U4 OLED adds to that versatility by replacing the original LCD (liquid crystal display) with a high-contrast graphical OLED display. With this monochrome 128×64 screen, you can present high-density data displays to help you analyze the Zumo’s status and sensor readings, or you can add some flair to your Zumo by showing eye-catching graphics.

We’ve updated our Arduino library for the Zumo 32U4 to add OLED display support as well as an LCD compatibility layer (the same way we did for the 3pi+), letting you easily convert existing programs to run on the OLED version or write new programs that will work on both old and new robots.

As with the LCD version, the new Zumo 32U4 OLED robot is available as a kit (with motors not included so you can select your own to customize performance) or as a fully assembled robot with your choice of 50:1, 75:1, or 100:1 motor options

|

|

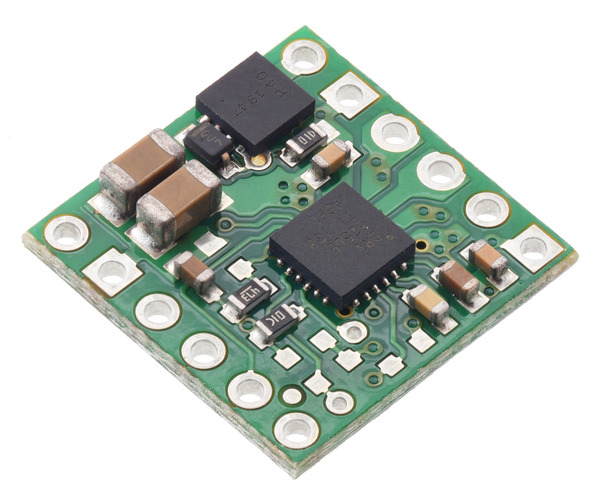

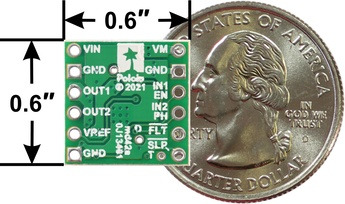

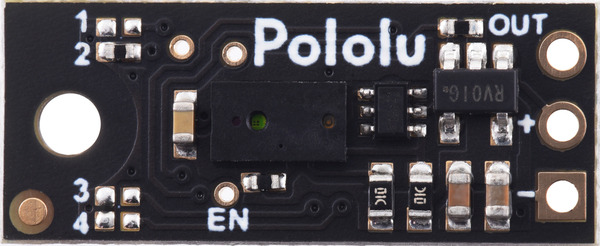

New products: DRV8256E/P motor driver carriers

We’re pleased to announce our inaugural products based on the DRV8256E and DRV8256P motor drivers from Texas Instruments, which we are especially excited about. These little carrier boards can deliver a continuous 1.9 A to a single brushed DC motor at voltages from 4.5 V to 48 V, so they have some of the broadest operating ranges of any of our drivers, and they can handle short bursts of considerably higher current (up to 6.4 A for less than a second). They also feature configurable active current limiting, which can help make them good choices for a motor that might only draw around an amp when running but much more when starting.

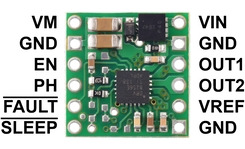

|

|

The DRV8256E and DRV8256P are very similar, and we use the same printed circuit board for both chips, but their control interfaces are different. The E version provides a phase/enable interface that lets you control a motor with a single PWM speed signal along with a simple digital direction signal, while the P version provides an IN/IN interface that gives you direct control over the motor outputs but requires two PWM signals for bidirectional speed control.

However, there is also a tradeoff with these two ICs. The DRV8256P uses drive/brake operation, shorting the motor outputs together and electrically braking the motor during the off portion. Many other TI drivers with phase/enable interfaces (like the DRV8838) also use drive/brake, but the DRV8256E does not: it operates in drive/coast mode, where the motor outputs are high impedance during the off portion of the PWM cycle, allowing the motors to coast. We don’t know why TI made a different decision for the DRV8256E, but it seems likely they have some high-volume customers who prefer it this way.

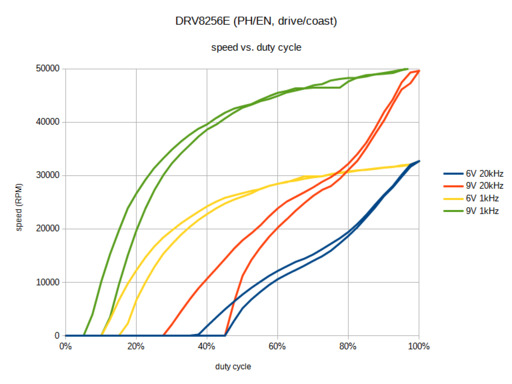

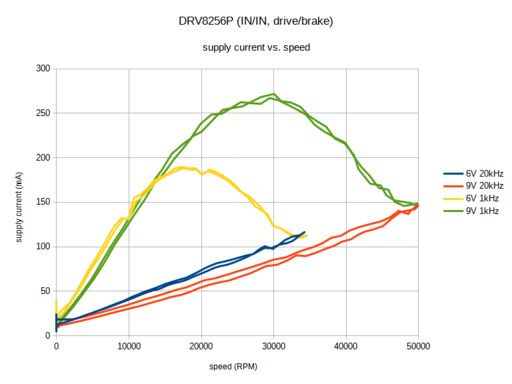

In our experience, drive/brake mode provides a much more linear relationship between PWM duty cycle and motor speed, so for an application where that is important, you might choose to accept the need for an additional PWM signal to get that improved linearity. These graphs show the difference in one specific scenario (powering a high-power micro metal gearmotor with no load):

|

|

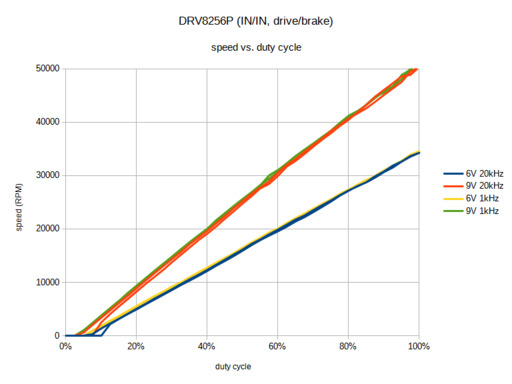

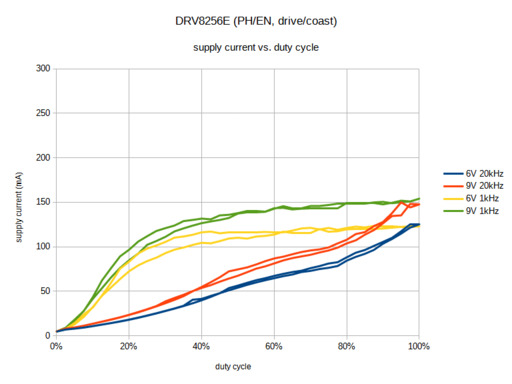

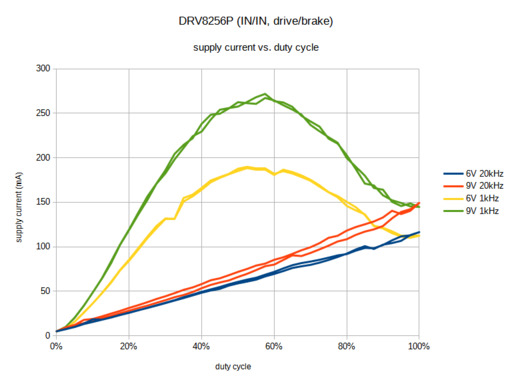

However, graphing the relationship between duty cycle and the current drawn by the motor driver from the supply reveals some more interesting differences. Specifically, at lower PWM frequencies, drive/brake operation uses much more current at intermediate duty cycles as the motor current ramps up and down for each PWM cycle:

|

|

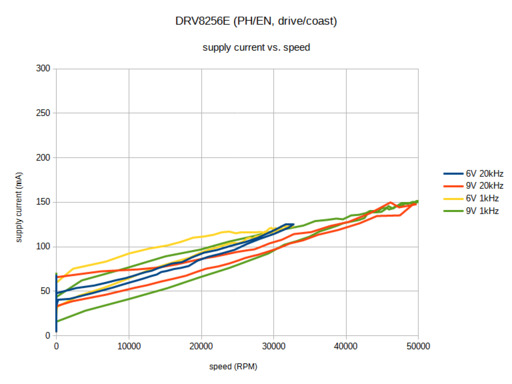

Finally, graphing current draw against motor speed shows that drive/coast can be more efficient for a given speed compared to drive/brake. So for an application with closed-loop speed control where it’s not as important for duty cycle to correspond linearly with speed, using drive/coast might be preferable if the PWM frequency is low.

|

|

If you have any thoughts about drive/brake vs. drive/coast and their use in different applications, we would be interested in hearing about it.

For more information about these drivers, see their product pages:

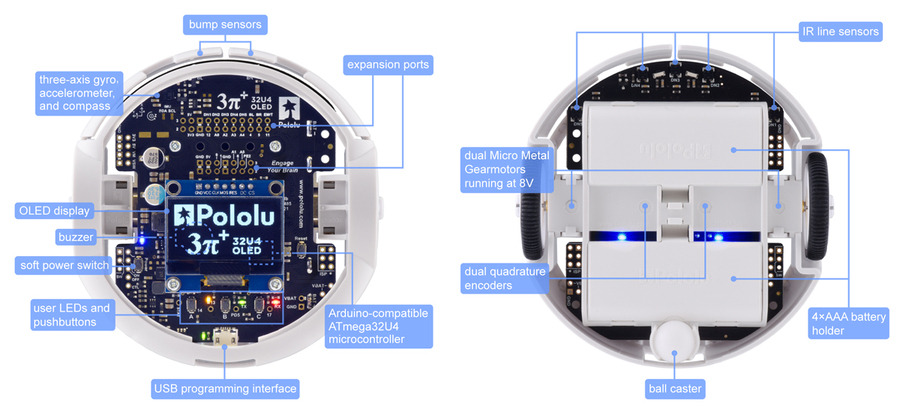

New 3pi+ 32U4 OLED Robot with graphical display!

We are very excited to announce that the 3pi+ 32U4 OLED Robot is now available! This is an updated version of the original 3pi+ 32U4 Robot that replaces the old LCD with a monochrome 128×64 OLED display, giving it the ability to display fancy high-contrast graphics while following a line course, navigating a maze, or doing whatever it is that you want this compact but versatile mobile platform to do.

|

|

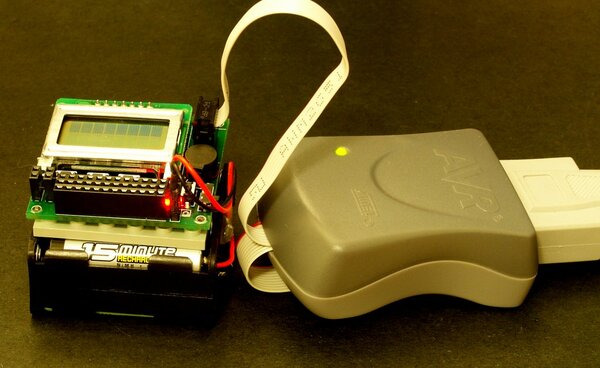

For more than 16 years, starting with some of our oldest products (from well before I joined Pololu), we have used HD44780-compatible alphanumeric liquid crystal displays on our robots and robot controllers. These LCDs have been around forever and are limited to displaying simple text on a fixed grid, but they are also ubiquitous: there are plenty of manufacturers still making displays that use the standard HD44780 interface.

|

Pololu Orangutan Robot Controller connected to an AVR ISP (serial version). |

|---|

It’s unlikely that we would have much difficulty sourcing this kind of display any time soon (as long as the pandemic doesn’t mess things up too badly), so using them in our products has always been a safe option despite their graphical limitations. The original 3pi+ 32U4 that we released late last year was our most recent design to include LCD support.

Meanwhile, monochrome organic light-emitting diode (OLED) displays have become increasingly popular in electronics over the last decade or so, and it’s not hard to see why: you can draw graphics on them, they can fit more information on the screen, they’re easier to read in the dark, and they just plain look cooler. But even though you might be able to go to eBay or Amazon and order a cheap OLED display for your project when you want one, it’s critical that we find a dependable supplier for a component like this before we can start to design it into our products.

That is why the availability of the 1.3″ OLED module we announced recently was actually a pretty big deal for us: it means that we finally have a source that we can rely on for larger quantities of these displays. The 3pi+ 32U4 OLED is the first of what we hope will be many robots and control boards that make use of the graphical capabilities offered by an OLED screen.

|

Like the original 3pi+ 32U4, the newer OLED version is available with three different motor options, either fully assembled or as a kit:

| 3pi+ 32U4 OLED Version | Products | Micro Metal Gearmotor | Top Speed | Comments |

|---|---|---|---|---|

| Standard Edition | assembled or kit | 30:1 MP 6V | 1.5 m/s | good combination of speed and controllability |

| Turtle Edition | assembled or kit | 75:1 LP 6V | 0.4 m/s | longest battery life, easiest to control, good for swarm robots or introductory robotics courses |

| Hyper Edition | assembled or kit | 15:1 HPCB 6V | ~4 m/s | very fast and difficult to control, easy to damage; only recommended for advanced users |

For anyone who wants to use different motors than the options above, the 3pi+ 32U4 OLED control board is likewise available separately and can be combined with a 3pi+ chassis and a pair of motors to build a custom robot.

We will be phasing out the original 3pi+ 32U4 robots and kits (they will remain available by special order), but that does not mean the old versions are suddenly obsolete or that you will have to learn an entirely new platform to use the new OLED version. Aside from the display interface, the hardware on the LCD and OLED versions is exactly the same, with features including encoders, line sensors, front bump sensors, and a full IMU (inertial measurement unit).

From a software perspective, it can actually be pretty challenging to work with graphics, especially on a small processor like the ATmega32U4. The simplicity of a text LCD can be an advantage in that you can essentially just ask it to do something like printing the letter “A” on the first column of the second row. On a graphical display, even if you just want to show some text, you have to define the shape of the letter in pixels; optionally composite that shape into a memory buffer; and then send the complete pixel data to the display. That means you have a lot more control over how that letter “A” is shown, but it takes a lot more work to do it.

To help get you started, we’ve developed an LCD compatibility layer as part of our Arduino library for the 3pi+ 32U4. This makes it easier to use the OLED screen for common display tasks, and it’s straightforward to write programs that will work on either version of the robot with minimal changes, since you can update an existing program to run on the OLED version by changing just a single line of code.

|

A 3pi+ 32U4 OLED and an original 3pi+ 32U4 running nearly identical programs and displaying the same text. |

|---|

Additionally, the same library makes it trivial to get the benefit of a higher-density text area: you can easily “upgrade” from an 8×2 character grid to an 11×4 or 21×8 layout.

|

Higher-density text layouts on the displays of some 3pi+32U4 OLED robots. |

|---|

We plan to continue improving our libraries to give you more options for efficiently working with both text and graphics on an OLED display; stay tuned for updates!

|

|

|

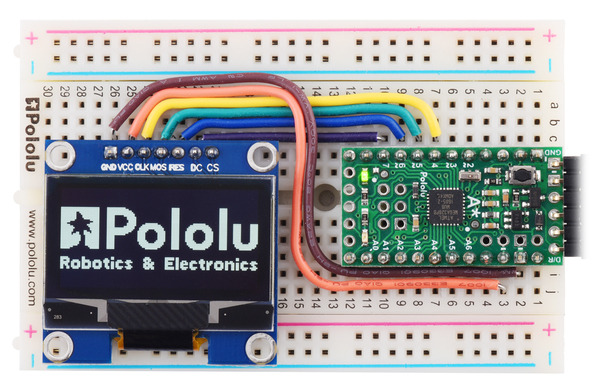

New product: 1.3" graphical OLED display

We’re now selling an OLED display module that you can use to add some fancy graphics to your project! This monochrome OLED screen measures 1.3 inches diagonally and uses a common SH1106 driver that can be controlled via SPI communication. (For more information, see its product page.)

|

Graphical OLED Display: 128×64, 1.3", White Pixels, SPI, Blue PCB, controlled by an A-Star 328PB Micro running at 3.3V. |

|---|

With a 128×64 grid of individually-controllable, high-contrast pixels, this OLED display can show a lot more information (and looks a lot cooler) than simple text-only LCD screens. We’re working on something that can take advantage of these enhanced graphical capabilities, so keep an eye out for updates!

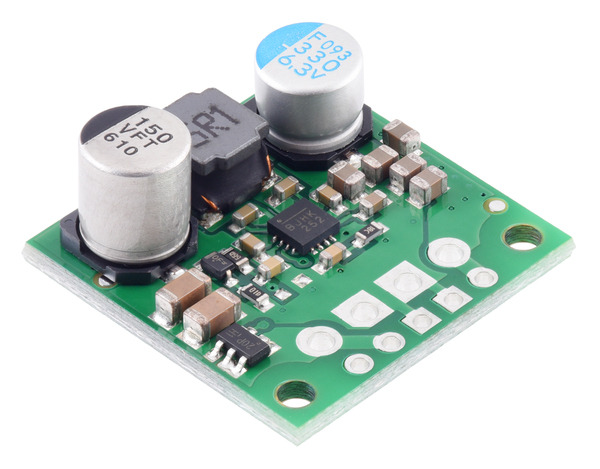

New product: 5V Step-Up/Step-Down Voltage Regulator S13V30F5

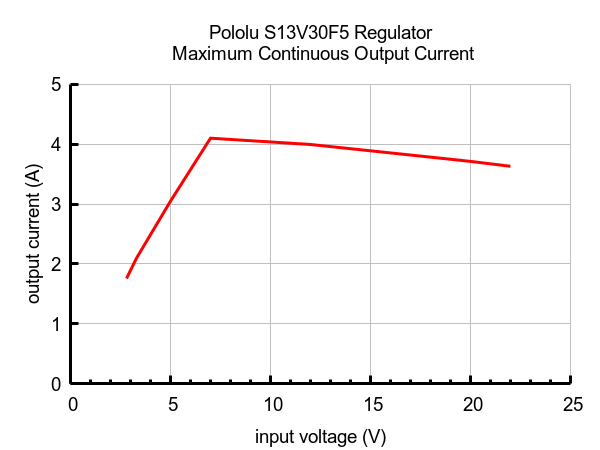

I started routing the PCB for the S13V30F5 5V step-up/step-down voltage regulator in January of 2020, and we were in the middle of testing the assembled prototypes when the pandemic shutdowns hit. Like lots of other things in 2020, the project got put on hold because appropriate testing requires a decent amount of equipment and is not the easiest thing to do remotely. That only makes it more exciting to announce that the S13V30F5, our most powerful step-up/step-down regulator, is now available! It operates from 2.8 V to 22 V and steps that voltage up or down as necessary to produce a fixed 5V output with typical efficiencies of 85% to 95%. As shown in the graph below, it can deliver around 3A continuously when the input is near 5V.

|

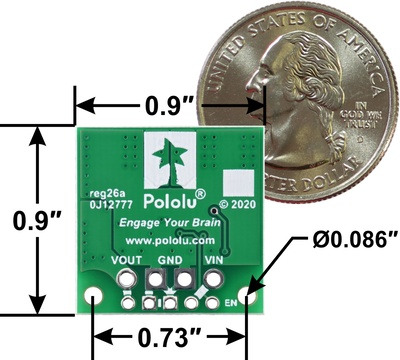

This new regulator measures just 0.9″ × 0.9″. That is almost half the size of our previously highest-power step-up/step-down units, the S18V20Fx family, which we have recently started rationing due to impacts from the global semiconductor shortages.

|

5V Step-Up/Step-Down Voltage Regulator S13V30F5, bottom view with dimensions. |

|---|

To help celebrate finally releasing the S13V30F5, we are offering an extra introductory special discount. The first hundred customers to use coupon code S13V30F5INTRO can get up to five units for just $9.95 each!

New high-speed linear actuators

We are excited to announce the addition of new GF23-series high-speed linear actuators to our already extensive linear actuator selection. This brand new Glideforce series from Concentric International is specifically designed for high-speed, light-duty applications, offering almost twice the speed of our previously fastest options while still supporting almost the same dynamic loads. This video demonstrates the speeds of the four types of light-duty actuators we carry:

They are available in 2″, 4″, 6″, 8″, 10″, and 12″ lengths with or without a feedback potentiometer. The table below shows how these new units compare to our other light-duty options, which are slower but stronger:

This brings our total selection of light-duty actuators to 48 options, and our total overall selection of linear actuators to 82 options, all stocked and available to ship the day you order.

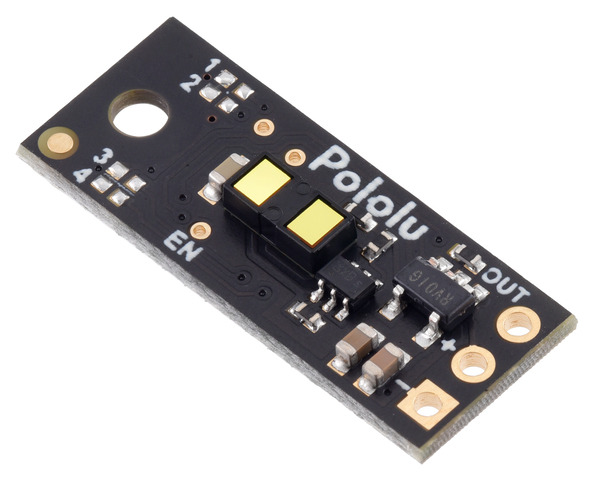

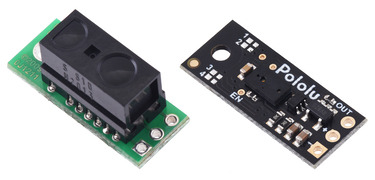

New longer-range Pololu distance sensors

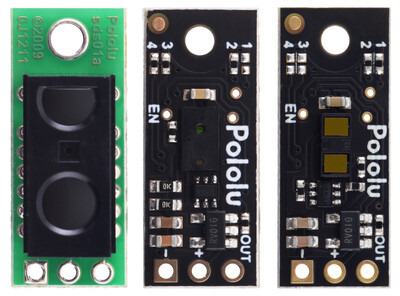

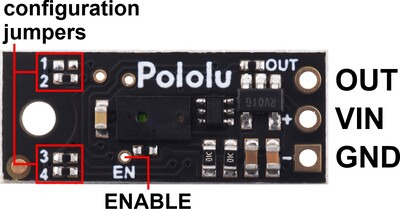

We released the first of our new Pololu distance sensors a few months ago, and now we’re releasing additional Pololu Digital Distance Sensors with longer ranges! These boards have the same form factor and pinout as both our old Sharp/Socle GP2Y0D8x carrier boards and the short-range Pololu distance sensors designed to replace those, but the new versions offer greatly increased detection and measurement ranges, opening up new possibilities in applications where longer-distance sensing capabilities are desired.

|

Comparison of a Pololu Carrier with Sharp GP2Y0D8x Digital Distance Sensor and two Pololu Digital Distance Sensors (irs16a and irs17a). |

|---|

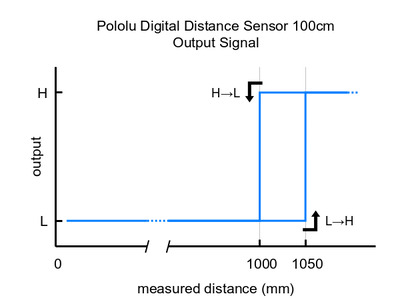

Like their shorter-range counterparts, these new Pololu distance sensors determine distance by using an integrated lidar module to measure the time of flight (ToF) of invisible, eye-safe infrared laser light. The new versions include four digital output versions, which simply indicate whether they detect an object within their respective range thresholds:

- Pololu Digital Distance Sensor 25cm

- Pololu Digital Distance Sensor 50cm

- Pololu Digital Distance Sensor 100cm

- Pololu Digital Distance Sensor 200cm

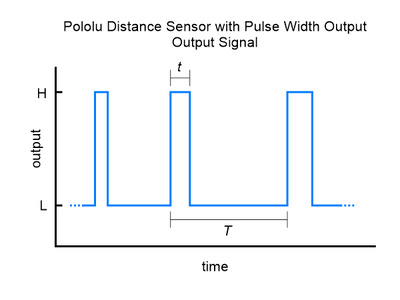

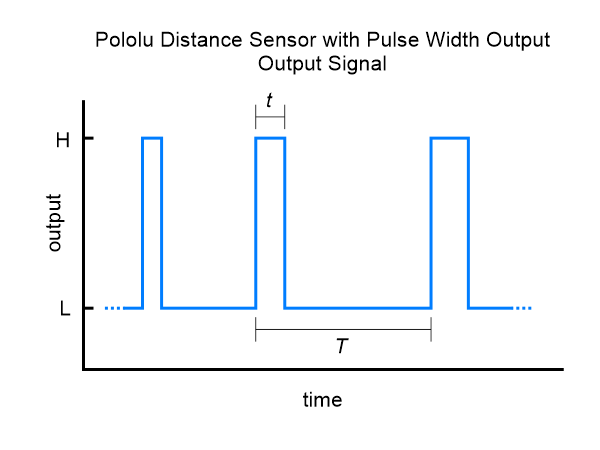

There are also two new versions with pulse width outputs, which encode a distance measurement in a pulsed signal:

- Pololu Distance Sensor with Pulse Width Output, 130cm Max

- Pololu Distance Sensor with Pulse Width Output, 300cm Max

(For more detail on how the different output types work, see the earlier announcement or the sensors’ product pages.)

|

|

This brings us up to ten different Pololu distance sensor options, as shown in these tables:

| Digital output (does not provide distance measurement) |

|||||

| Sensor | Maximum range1 |

Minimum range |

Minimum update rate |

Jumper settings (4321) |

PCB ID |

|---|---|---|---|---|---|

| #4050: Digital output, 5cm | 5 cm | < 5 mm | 145 Hz | 0000 | irs16a |

| #4052: Digital output, 10cm | 10 cm | < 5 mm | 115 Hz | 0010 | |

| #4054: Digital output, 15cm | 15 cm | < 5 mm | 95 Hz | 0100 | |

| #4066: Digital output, 25cm | 25 cm | < 1 mm | 100 Hz | 0000 | irs17a |

| #4067: Digital output, 50cm | 50 cm | < 1 mm | 100 Hz | 0001 | |

| #4069: Digital output, 100cm | 100 cm | < 1 mm | 100 Hz | 0011 | |

| #4077: Digital output, 200cm | 200 cm | < 1 mm | 30 Hz | 1011 | |

| Pulse width output (provides distance measurement) |

||||||

| Sensor | Maximum range1 |

Minimum range2 |

Resolution | Minimum update rate |

Jumper settings (4321) |

PCB ID |

|---|---|---|---|---|---|---|

| #4064: Pulse width output, 50cm max | ~50 cm | 1 cm | 3 mm | 50 Hz | 1110 | irs16a |

| #4071: Pulse width output, 130cm max | ~130 cm | 4 cm | 1 mm | 100 Hz | 0101 | irs17a |

| #4079: Pulse width output, 300cm max | ~300 cm | 4 cm | 2 mm | 30 Hz | 1101 | |

1 Effective range depends on object reflectivity and ambient lighting conditions.

2 Objects closer than the minimum distance can still be detected, but the measured distance might be inaccurate. The minimum detection range is < 5 mm for irs16a boards and < 1 mm for irs17a boards.

We’ve also just published comprehensive information about all the possible jumper settings for these sensor boards on their respective product pages. By changing the jumper connections, you can make a sensor act like a different version or even select another configuration that isn’t available as a standard product. (And if you have a special volume requirement, we can manufacture a custom batch of sensors for you; please contact us for more information.)

Once again, we are offering an extra introductory special discount on these sensors, to help share in our celebration of releasing new products. The first hundred customers to use coupon code DISTSENSORS can get up to three units of each type (including the shorter-ranged versions released earlier) for just $9.95 each!

New Pololu distance sensors with digital and pulse width outputs

In many applications ranging from robotics to industrial automation, it is useful to quickly detect the presence of objects within a certain distance. Our carrier boards for the Sharp/Socle GP2Y0D8x digital distance sensors have been popular in this role, but those sensors are unfortunately no longer being produced and are becoming hard to find. So we are excited to announce the release of our next-generation lidar-based Pololu Digital Distance Sensors, which can replace the discontinued Sharp sensors and more!

These new sensors use an on-board rangefinder module to determine distance by measuring the time of flight (ToF) of invisible, eye-safe infrared laser light. They are available in three different digital output versions with the same range thresholds as the GP2Y0D8x series:

- Pololu Digital Distance Sensor 5cm

- Pololu Digital Distance Sensor 10cm

- Pololu Digital Distance Sensor 15cm

We also have one additional option for more advanced applications:

(More on that version below.)

|

A camera with no IR filter shows the infrared light emitted by a Pololu Digital Distance Sensor (this light is eye-safe and not visible to the naked eye). |

|---|

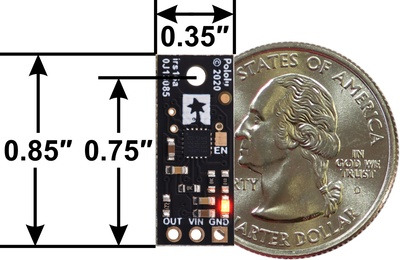

The Pololu Digital Distance Sensors work like the Sharp sensors: they operate with either a 3.3 V or 5 V supply and output a simple digital signal, which is low if an object is detected within the specified range, high otherwise. They have the same indicator LED, pinout, and form factor as our GP2Y0D8x carrier boards (but are much thinner than the Sharp sensors), allowing them to be drop-in replacements in most applications.

|

The pulse width output version looks almost identical to its digital output counterparts, but instead of simply indicating the presence or absence of an object, it outputs a pulsed signal (similar to a hobby servo control signal) that encodes the distance it is measuring in the length of each high pulse. By timing these pulses, you can get quantitative range readings for targets up to half a meter away (depending on reflectance and environmental conditions).

|

The four numbered surface-mount jumpers on these sensors’ printed circuit boards, near the mounting hole on the front side, determine the sensor’s operating mode. You can change the jumper connections yourself to customize its behavior and even effectively convert the sensor into a different version (more information on the jumper settings will be available soon). And since we assemble and program these boards here in our Las Vegas facility, we can produce a custom-configured batch of sensors for you. If you are interested in manufacturing customization, please contact us for more information.

|

We are back to offering an introductory special discount on new products, to help share in our celebration of releasing these Pololu distance sensors. The first hundred customers to use coupon code DISTSENSORS can get up to three units of each type for just $7.87 each!

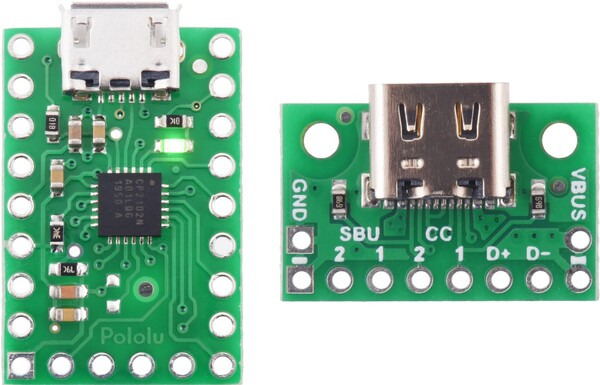

New products: CP2102N serial adapter and another USB Type-C breakout. Should we do more with USB-C?

Seven years ago, we released a CP2104 USB-to-Serial Adapter Carrier, our first product with a USB Micro-B connector (we had only used Mini-B up to that point). A few months later I wrote a blog post discussing our decision to switch connector types, and since then, we have exclusively used the Micro-B connector in all of our USB products.

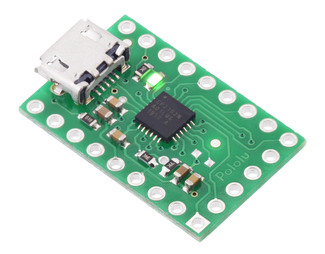

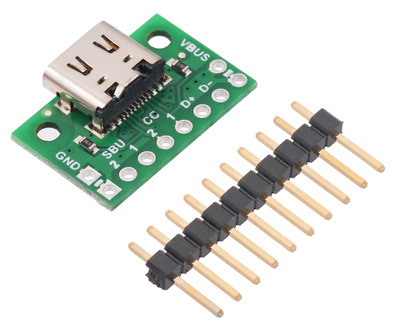

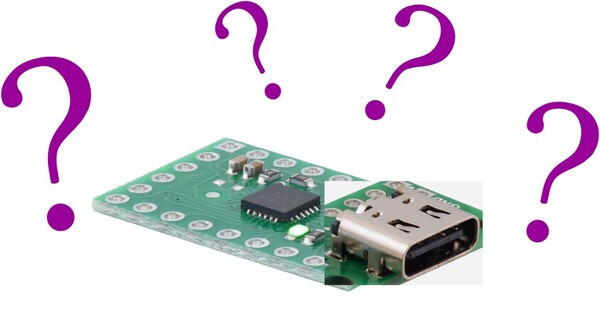

Well, it’s now 2020 and we recently released a CP2102N USB-to-Serial Adapter Carrier to replace the CP2104 board, along with a breakout for a different type of USB connector: our USB 2.0 Type-C Connector Breakout Board (usb07b). These products do not seem to have much in common at first glance (other than both being related to USB), but I think they create a good opportunity to talk about USB connectors again.

First, a bit about these new boards:

|

The CP2102N is Silicon Labs’ replacement for several of their older USB-to-UART bridge ICs that are going out of production, including the CP2104. (It is not to be confused with the even older CP2102 without the “N”, featured on our first USB-to-serial adapter and also being phased out.) Compared to the CP2104, the CP2102N has similar functionality but includes a few small improvements, such as a higher maximum baud rate and a re-programmable configuration ROM. Our CP2102N carrier can be used as a drop-in replacement for our CP2104 board in most applications. For more information, see the product page for the CP2102N USB-to-Serial Adapter Carrier.

|

Our usb07b connector breakout board is very similar to the first Type-C breakout (usb07a) that we released last year. The two boards use different styles of connectors, and the newer one is priced a bit lower, but they both provide access to all of the USB-C connections required for USB 2.0 operation (power, USB 2.0 data, configuration, and sideband pins) and feature integrated CC pull-down resistors that make it easy to use the port as a power sink. For more information, see the product page for the USB 2.0 Type-C Connector Breakout Board (usb07b).

So now, the obvious question is: Why doesn’t this new serial adapter have a USB Type-C connector?

|

When we designed and released the CP2104 board in 2013, the USB Type-C connector did not even exist yet. (Its development was probably well under way, but the specification was not finalized until August 2014.) Since then, USB-C connectors have started appearing in all kinds of devices and are becoming increasingly widespread. They offer the promise of a single type of connector that can be used everywhere, supporting faster data transfer, higher power, and alternate modes. On top of all that, the connector is reversible, so you don’t have to worry about getting the orientation of the plug right.

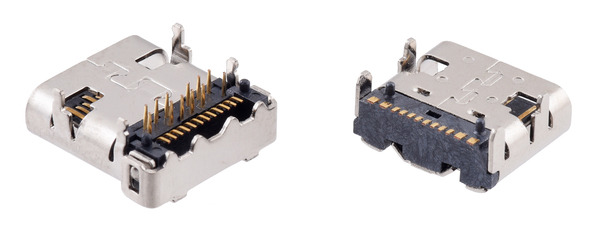

With those advantages in mind, it’s reasonable to wonder why we haven’t started using the Type-C connector in more products. I touched on some of the challenges introduced by USB Type-C when I announced for our first USB-C breakout board, and that increased complexity accounts for part of the explanation here. A full-featured Type-C connector like the one on usb07a has 24 separate pins, way more than the five on a Micro-B connector, which means it’s significantly harder both to design a printed circuit board for it and to ensure good quality and yields when manufacturing that board (especially since half of the contacts on the usb07a connector are small, tightly-packed through-hole pins). Because it is more mechanically complex, the Type-C receptacle usually also costs quite a bit more than a Micro-B connector.

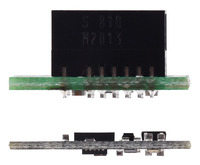

The connector on our new usb07b board improves the situation a bit. It does not expose the eight USB 3 SuperSpeed signals (which we did not make available on our usb07a breakout anyway), and some of the power and ground pins are paired up more conveniently. So this connector effectively has just 12 pins, and they are all surface-mount, which helps lessen some of the design and manufacturing challenges I mentioned. The connector’s simpler construction makes it slightly less expensive as well.

|

Bottom view comparison of the USB Type-C connectors used on our usb07a (left) and usb07b (right) breakout boards. |

|---|

This means it’s now a little bit more practical for us to consider a Type-C connector for more applications. However, there is still some question of what is to be gained by switching to it. While the enhanced power delivery capabilities of USB 3 and Type-C might open up some interesting possibilities for new kinds of devices, it’s not clear that our existing products would benefit much from a change to USB-C, and there are some features like SuperSpeed communication that we are not likely to take advantage of anytime soon with the types of electronics we make.

So we want to ask you: what products, revised or new, would you like to see us make with USB Type-C? Would a device have to be uniquely enabled by Type-C in order to be compelling (maybe something like a USB bus-powered motor controller), or is just having a reversible connector alone worth it, and would you be willing to pay a couple extra dollars to get something with a Type-C connector instead of Micro-B? What else about USB-C appeals to you? Please let us know in the comments!

New products: JST SH-Style cables and connectors for Micro Metal Gearmotor encoders

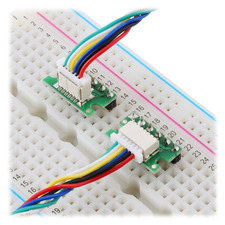

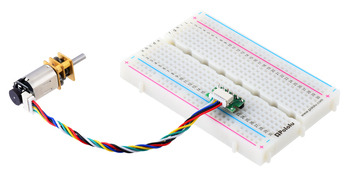

|

|

We have expanded our selection of JST SH-style cables and connectors! These cables and connectors are ideal for use with our magnetic encoders for Micro Metal Gearmotors as seen in the photo on the right above.

In addition to the 6-pin single-ended female JST SH-style cables we’ve offered for a while, we now offer 6-pin female-female JST SH-style cables in five different lengths. Here’s the full list of currently available options:

- 6-Pin Female-Female JST SH-Style Cable 10 cm

- 6-Pin Female-Female JST SH-Style Cable 16 cm

- 6-Pin Female-Female JST SH-Style Cable 25 cm

- 6-Pin Female-Female JST SH-Style Cable 40 cm

- 6-Pin Female-Female JST SH-Style Cable 63 cm

- 6-Pin Single-Ended Female JST SH-Style Cable 12 cm

- 6-Pin Single-Ended Female JST SH-Style Cable 30 cm

- 6-Pin Single-Ended Female JST SH-Style Cable 75 cm

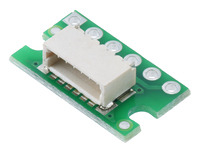

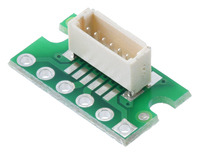

To go along with the new female-female cables, we also have breakout boards available for both the side-entry and top-entry versions of the JST SH-style connector. When used with our encoders and JST cables, these breakout boards offer a convenient way to access the encoder signal and power pins through a breadboard, and the pins are labeled on the board’s bottom silkscreen with this application in mind. Alternatively, these boards can serve as general-purpose breakouts for other applications that do not involve encoders. For example, a pair of connector breakouts with a female-female cable could be used as a removable general-purpose interconnect between different parts of a modular system.

|

|

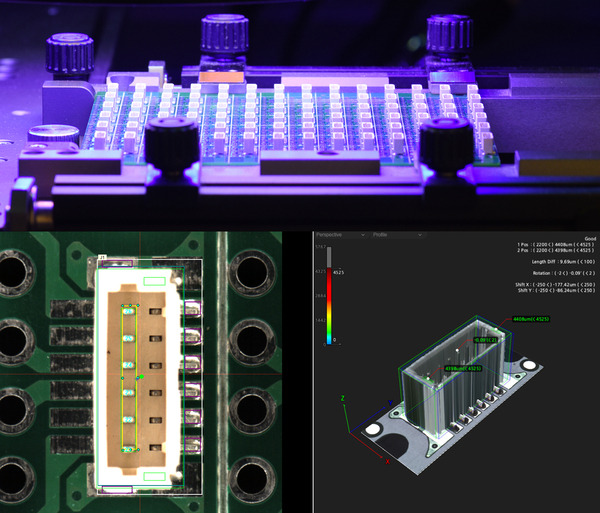

We are trying something new with how we package and sell these connector boards. At Pololu, all our electronics undergo functional testing, where each product is placed on a custom testing apparatus and checked for functionality. This is a labor intensive step in our production process, and for a product as simple as these connector boards, testing and packaging represent a significant amount of the cost to produce it. As such, we are offering two options for purchasing these connector boards: either fully tested and individually packaged, or an untested pack of three.

|

|

Even though we do not functionally test the discounted 3-packs, each one undergoes automated optical inspection (AOI) to visually check the placement of the connector and the quality of the solder joints. Additionally, each printed circuit board (PCB) is electrically tested by our PCB manufacturer, so we know the PCB itself is free from electrical defects. This makes it very unlikely for any of the breakout boards to be bad.

The additional functional testing we perform on the fully tested units just confirms the solder connections between the connector and the board. If you purchase the untested units but would still like this additional confirmation, you can easily check it yourself with a multimeter. (Just use it to check for continuity between corresponding pins on the actual JST connector and through-holes on the board, and verify that there is no continuity between adjacent pins.) In the unlikely event you receive a unit with a poor or shorted connection, you should be able to touch it up yourself with a soldering iron. So for common applications that require two boards, such as use with a pair of encoders, you have the option of two individually packaged units we have confirmed functional or, for the same price, three units that have passed visual inspection and are very likely to leave you with two functional units plus a spare.

|

All units automatically optically inspected. |

|---|

Here are all of our 6-pin JST SH-style connector options:

- Breakout for JST SH-Style Connector, 6-Pin Male Top-Entry (Individually Packaged)

- Breakout for JST SH-Style Connector, 6-Pin Male Top-Entry (3-Pack Untested)

- Breakout for JST SH-Style Connector, 6-Pin Male Side-Entry (Individually Packaged)

- Breakout for JST SH-Style Connector, 6-Pin Male Side-Entry (3-Pack Untested)

All of these cables and connectors and the encoders they are compatible with can be found here. And you can get 15% off the encoders and cables using coupons from our Christmas Sale going on now!

What do you think about this kind of approach where we test something less thoroughly in order to offer it at a lower price? Would you prefer it over the fully tested option? Do you think one option will be more popular than the other? We’d love to hear your thoughts!