Pololu Blog »

Pololu Blog (Page 4)

Welcome to the Pololu Blog, where we provide updates about what we and our customers are doing and thinking about. This blog used to be Pololu president Jan Malášek’s Engage Your Brain blog; you can view just those posts here.

Popular tags: community projects new products raspberry pi arduino more…

Labor Day Sale going on now!

We are having a Labor Day sale starting now through Tuesday, September 5! Check out the sale page for more information. Please note that we will be closed Monday, so orders placed after 2 PM Pacific Time Friday, September 1 will be shipped on Tuesday, September 5.

Independence Day Sale going on now!

We are having an Independence Day sale starting now through Wednesday, July 5! Check out the sale page for more information. Please note that we will be closed Tuesday, so orders placed after 2 PM Pacific Time Monday, July 3 will be shipped on Wednesday, July 5.

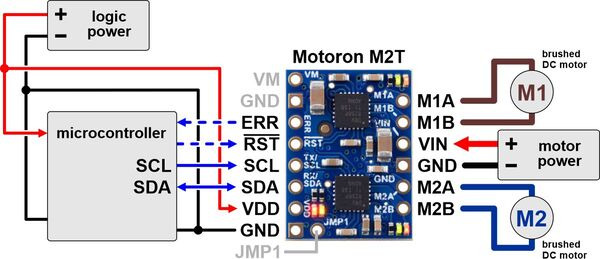

More Motoron motor controllers!

We recently added six new low-power variants to our Motoron line of basic serial motor controllers: four Mxx550 1- and 2-channel versions, as well as 3-channel versions for Arduino (M3S550) and Raspberry Pi (M3H550).

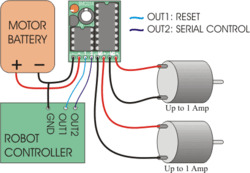

1- and 2-channel micro motor drivers

The new M1T550, M1U550, M2T550, and M2U550 are single- and dual-channel serial motor controllers in a micro footprint. With a maximum motor supply voltage of 22 V, the Mxx550 versions are a great way to control small motors powered by power supplies up to 12 V and battery packs up to 12 cells in series for alkaline, NiCd, and NiMH, or up to 4 cells in series for LiPo. These are lower-voltage, pin-compatible versions of the Mxx256 models we released earlier this year, which have a maximum motor voltage of 48 V and can deliver slightly more current but are otherwise almost identical.

Here is the full array of tiny Motoron options, including I²C and UART serial interface versions:

| Motoron motor controllers micro versions |

||||

M1T550  M1U550 |

M2T550  M2U550 |

M1T256  M1U256 |

M2T256  M2U256 |

|

|---|---|---|---|---|

| Control interface: | I²C or UART serial | |||

| Motor channels: | 1 (single) | 2 (dual) | 1 (single) | 2 (dual) |

| Minimum motor supply voltage: |

1.8 V | 4.5 V | ||

| Absolute max motor supply voltage: |

22 V | 48 V | ||

| Recommended max nominal battery voltage: |

16 V | 36 V | ||

| Max continuous current per channel: |

1.8 A | 1.6 A | 2.2 A | 1.8 A |

| Available versions with I²C: |

||||

| Available verions with UART serial: |

||||

| Price: | $12.49 – $14.49 | $15.95 – $17.95 | $16.95 – $18.95 | $23.95 – $25.95 |

3-channel motor drivers for Arduino and Raspberry Pi

We also released larger (but still small!), 3-channel versions in Arduino (M3S550) and Raspberry Pi (M3H550) compatible form factors. These again have a maximum motor supply voltage of 22 V and correspond to the 48 V max M3S256 and M3H256 versions we released in 2022. Here is the full line of larger Motoron serial motor controllers, including the even higher-power, dual-channel Motorons in full-size Arduino Shield or Raspberry Pi Hat form factors:

| Motoron motor controllers Arduino and Raspberry Pi form factor versions |

||||||

M3S550  M3H550 |

M3S256  M3H256 |

M2S24v14  M2H24v14 |

M2S24v16  M2H24v16 |

M2S18v18  M2H18v18 |

M2S18v20  M2H18v20 |

|

|---|---|---|---|---|---|---|

| Control interface: | I²C | |||||

| Motor channels: | 3 (triple) | 2 (dual) | ||||

| Minimum motor supply voltage: |

1.8 V | 4.5 V | 6.5 V | |||

| Absolute max motor supply voltage: |

22 V | 48 V | 40 V | 30 V | ||

| Recommended max nominal battery voltage: |

16 V | 36 V | 28 V | 18 V | ||

| Max continuous current per channel: |

1.7 A | 2 A | 14 A | 16 A | 18 A | 20 A |

| Available versions for Arduino: |

M3S550 | M3S256 | M2S24v14 | M2S24v16 | M2S18v18 | M2S18v20 |

| Available versions for Raspberry Pi: |

M3H550 | M3H256 | M2H24v14 | M2H24v16 | M2H18v18 | M2H18v20 |

| Price: | $20.95 – $30.95 | $34.95 – $44.95 | $59.95 – $69.95 | $115.95 – $124.95 | $59.95 – $69.96 | $95.95 – $104.95 |

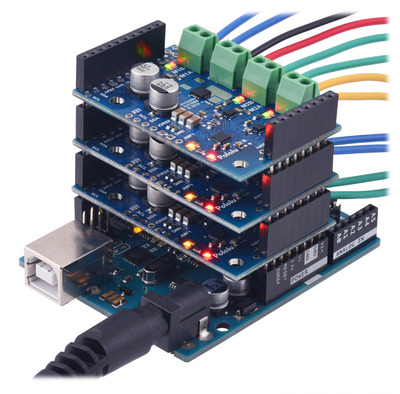

The great thing about the Motorons is that you can easily string together or stack multiple controllers, mixing and matching sizes to fit your application. For example, you could use one high-power dual motor version for drive motors on a mobile robot and then add a smaller 3-channel motor controller for additional actuators. This arrangement with three stacked Motorons on an Arduino Uno allows simple control of up to 9 motors:

|

The common protocol between versions also makes it easy to change motor sizes and to reuse your code between projects. Want to make a bigger version of your first prototype? Just use a higher-power Motoron! Want to make a tiny robot next time? Use a tiny Motoron! Want to… you get the idea.

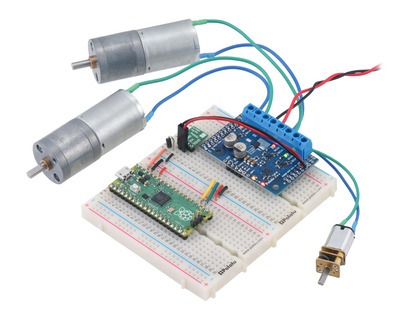

While the 3-channel boards are designed to stack on Arduinos or Raspberry Pis, they are also easy to use on breadboards:

|

It may be easy to view the six new Mxx550 Motorons as just lower-voltage versions of the previously available Mxx256 Motorons, but I am especially excited about them because we are able to offer them at a very low price, extending the legacy of the Dual Serial Motor controllers that were among our first products over 20 years ago. We are launching the 2-channel M2T550 and M2U550 at just $15.95, a lower price than the original Dual Serial Motor controller from 2001 (without even adjusting for inflation!).

|

|

The chip shortages of the past several years have made it especially difficult to introduce new products and to keep their prices down, but things are finally seeming to get better on that front. You can see in the tables above that the higher-power 2-channel Motorons are much more expensive; those prices are still elevated because we are limited on some critical components we use there and in our other products. We should be able to manufacture plenty of the new Motorons without being constrained in a similar way.

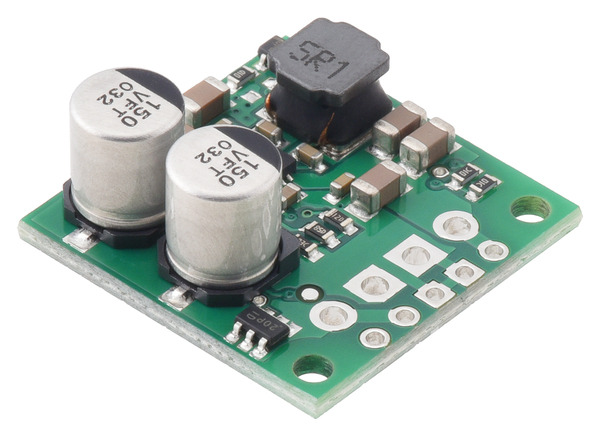

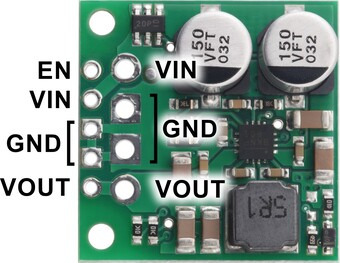

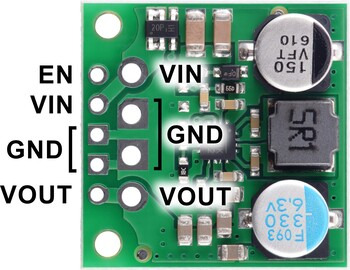

New products: S13V25Fx step-up/step-down voltage regulators with fixed 3.3V to 15V output voltages

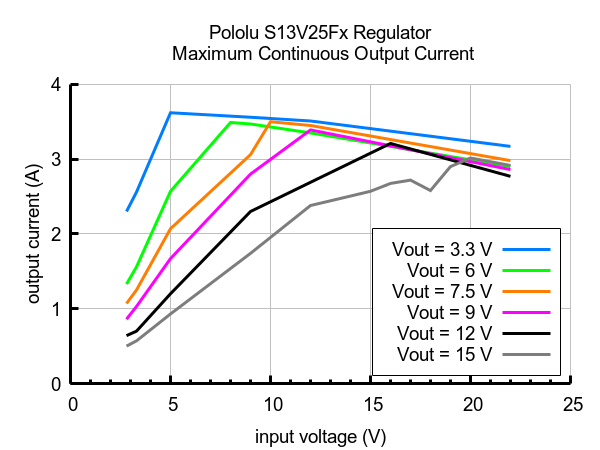

We have expanded our S13VxFx family of step-up/step-down voltage regulators to include options with a variety of output voltages from 3.3 V to 15 V. Like the original 5 V members of the family, these new S13V25Fx units take an input voltage from 2.8 V to 22 V and efficiently increase it or decrease it as necessary to produce the regulated output voltage. Even with their compact 0.9″ × 0.9″ size, they can deliver typical continuous output currents between 1 A and 3 A, making them our most powerful buck-boost converters. (That’s almost half the size of our previously highest-power step-up/step-down units, the S18V20Fx family, which are still being impacted by the global semiconductor shortages.) The graphs below show a more complete picture of the kinds of currents you can expect for different combinations of input and output voltages:

|

These new S13V25Fx versions do not include a 5V option because we already have that in the S13V30F5. They are pin-compatible with that 5V module and have the same overall board dimensions, but please note that the tall components (i.e. electrolytic capacitors and inductor) are in different locations. Here is a comparison of the new S13V25Fx regulators (left) next to the S13V30F5 (right):

|

|

This table shows what the full family looks like now:

| Regulator | Output voltage | Typical max continuous output current | Input voltage range | Typical efficiency | Size | Price |

|---|---|---|---|---|---|---|

| #4083: S13V10F5 | 5 V | 1 A | 2.8 V – 22 V | 85% – 95% | 0.35″ × 0.475″ | $6.95 |

| #4084: S13V15F5 | 5 V | 1.5 A | $8.95 | |||

| #4085: S13V20F5 | 5 V | 2 A | $12.95 | |||

| #4082: S13V30F5 | 5 V | 3 A | 0.9″ × 0.9″ | $12.95 | ||

| #4980: S13V25F3 New! | 3.3 V | 2.5 A | $13.95 | |||

| #4981: S13V25F6 New! | 6 V | 2.5 A | $13.95 | |||

| #4982: S13V25F7 New! | 7.5 V | 2.5 A | $13.95 | |||

| #4983: S13V25F9 New! | 9 V | 2.5 A | $13.95 | |||

| #4984: S13V25F12 New! | 12 V | 2.5 A | $13.95 | |||

| #4985: S13V25F15 New! | 15 V | 2.5 A | $13.95 |

As a reminder, we manufacture these boards in-house at our Las Vegas facility, so we have the flexibility to make these regulators with custom fixed output voltages. If the voltage you need is not one of our standard options and you are interested in customization, please contact us.

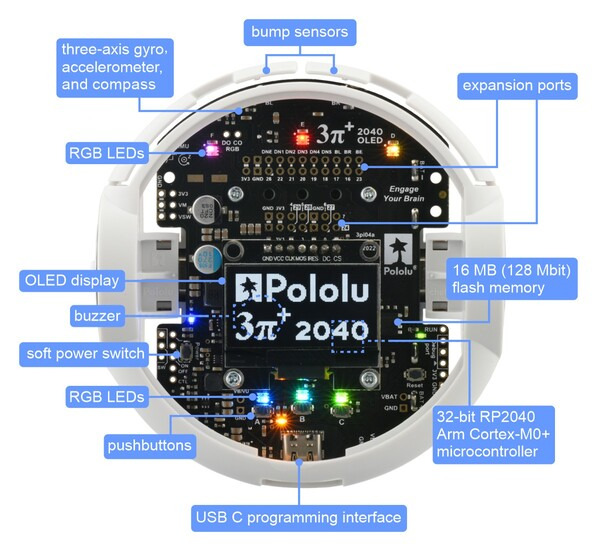

3pi+ 2040 Robot full release with additional motor options

We have transitioned from our initial early-adopter release to a full release of the 3pi+ 2040 Robot family! With the full release, we also have some additional motor options. Here’s the full lineup:

| 3pi+ 2040 Version | Products | Micro Metal Gearmotor | Top Speed | Comments |

|---|---|---|---|---|

| Standard Edition | assembled or kit | 30:1 MP 6V | 1.5 m/s | good combination of speed and controllability |

| Turtle Edition | assembled or kit | 75:1 LP 6V | 0.4 m/s | longest battery life, easiest to control, good for swarm robots or introductory robotics courses |

| Hyper Edition | assembled or kit | 15:1 HPCB 6V | ~4 m/s | very fast and difficult to control, easy to damage; only recommended for advanced users |

The Turtle Edition is a great choice for educational environments or anyplace else where slow, controlled speed is important. On the flip side, the Hyper Edition uses high-power motors with a low-gear-ratio gearbox to offer a LOT of speed, but this also means reduced control and a higher risk of the robot damaging itself, so we only recommend it for advanced users who want to push the limits of what this robot platform can do. We also make the 3pi+ 2040 control board and 3pi+ chassis available separately for those who would like to do something custom with one of our many other Micro Metal Gearmotor options.

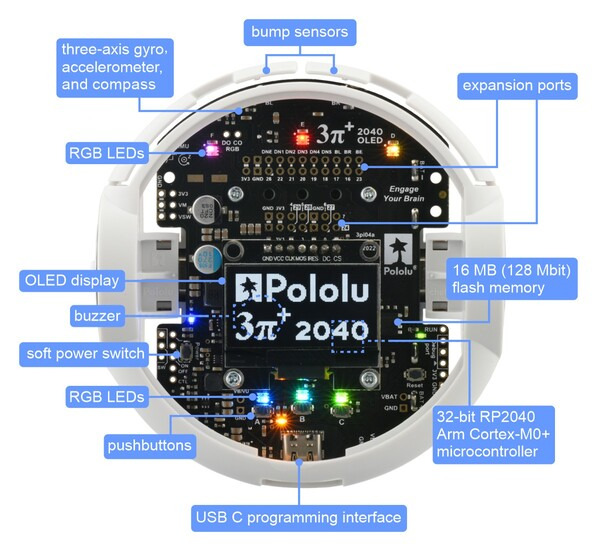

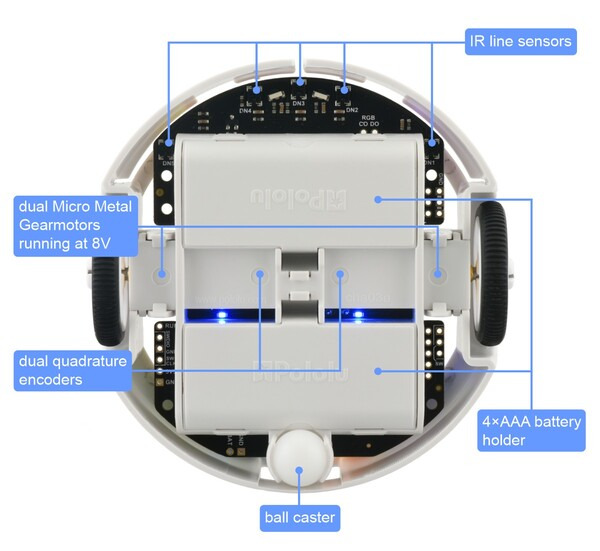

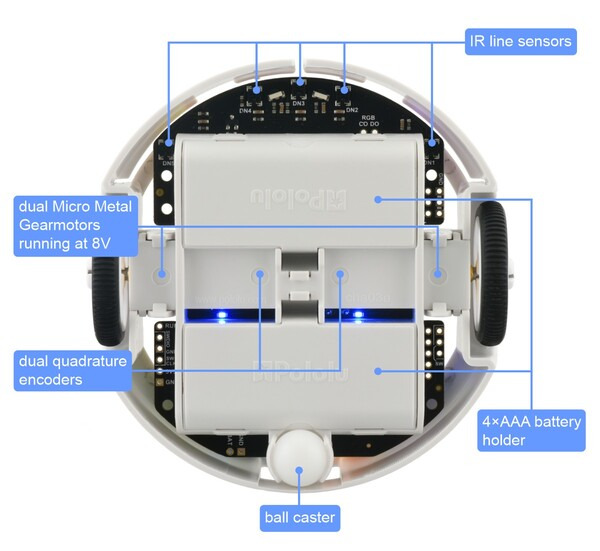

To recap from our early adopter release announcement, this robot combines our 3pi+ chassis with the power of the Raspberry Pi RP2040 microcontroller, and it’s full of cool features:

|

|

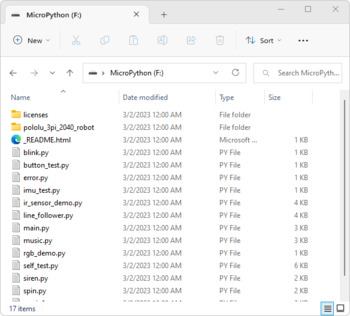

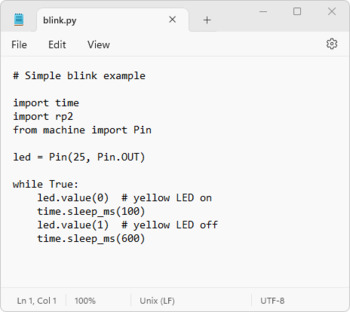

We have a comprehensive set of example Python programs to help get you started using all of these features, and we expect to continue adding more over time. Let us know if there’s something in particular you would want to see that is not already covered!

|

|

Moving sculpture Kinetic Little Rain

This hypnotic video from customer Alain Haerri shows Kinetic Little Rain, a moving sculpture that was inspired by the sculpture Kinetic Rain in the Changi Airport in Singapore. Alain’s sculpture features 100 blown glass drops that are moved by stepper motors. Each motor is driven by its own Tic T500 Stepper Motor Controller and the whole setup is controlled by an Arduino Mega 2560.

Memorial Day Sale going on now!

If you have followed the electronics industry or even general news, you’ll know that for the past several years we’ve been dealing with parts shortages, rationing, and associated price increases. We are relieved to finally be getting net increases in parts on hand! In the past few months we have taken hundreds of products off rationing, and we are celebrating and highlighting them in our Memorial Day Sale. Use coupon code MEMORIALDAY23 to save 23% on all non-rationed Pololu-brand products with an “Active” or “Active and Preferred” status, limit 5 units per item, now through Tuesday, May 30.

Check out the sale page for more information. Please note that we will be closed Monday, so orders placed after 2 PM Pacific Time Friday, May 26 will be shipped on Tuesday, May 30.

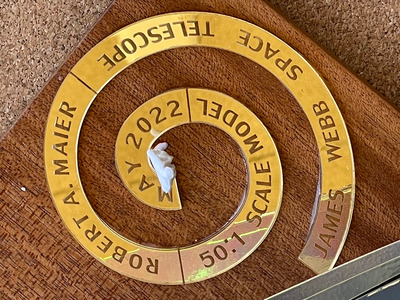

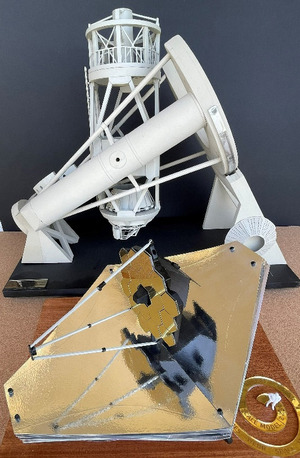

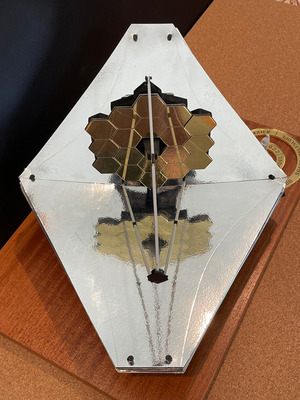

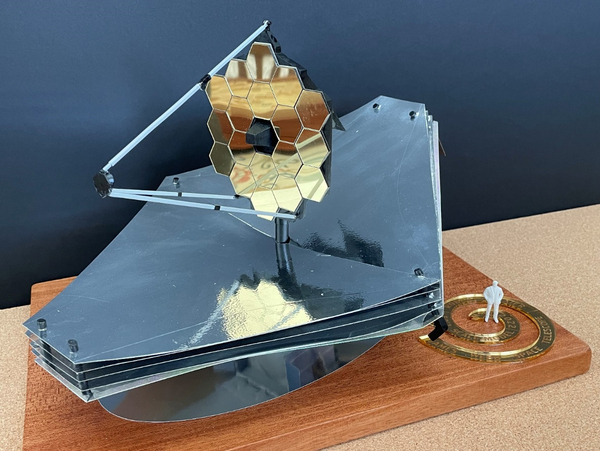

Laser cutting part of a 50:1 model of the James Webb Space Telescope

|

50:1 scale model of the James Web Space Telescope model with laser-cut and etched gold-mirror acrylic and gold-mirror styrene parts. |

|---|

Retired aerospace engineer Robert Maier shared with us this awesome 50:1 scale model of the James Webb Space Telescope (JWST) he made with his brother Mark and a little help from our custom laser cutting service. We cut the JWST’s main mirrors for him out of 1.5 mm gold mirrored styrene sheets from Midwest Products, and the hexagon patterns were laser etched onto the surface. He also had us laser cut various silicone bands to hold the moving pieces of the structure as the model folds/unfolds.

|

|

We more commonly work with 3 mm mirrored acrylic, but the model’s mirror required something thinner, and the more expensive styrene was perfect for the job. For comparison, the spiral label sitting beneath the figurine’s feet was cut from gold mirror acrylic.

|

|

Mark uses the model in the Astronomy 101 classes he teaches at San Jacinto College in Southern California. He recently wrote an article about the model, which is published in the April 2023 issue of Sky and Telescope magazine (it’s on page six). Additional photos of the model are included below, and even if you’re not a subscriber to the magazine, you can preview the article online.

Do you have a fun idea in mind that can benefit from laser-cut parts? Submit a quote request or contact us to discuss how we can help.

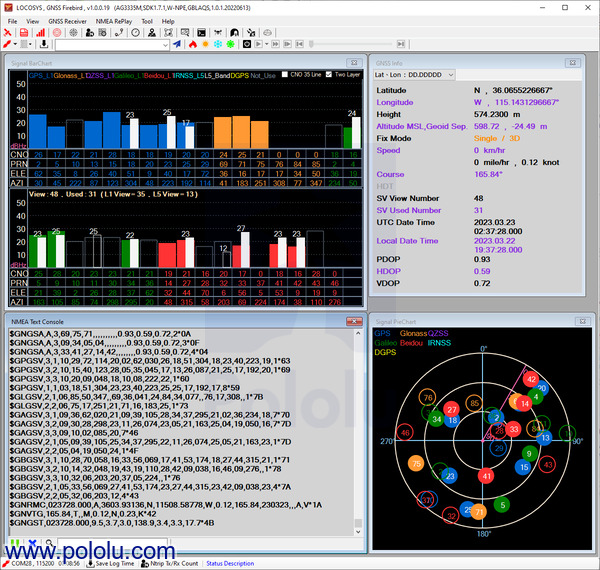

New product: LOCOSYS LC20031-V2 135-Channel Dual-Band GNSS Receiver Module

We’re now selling the LC20031-V2 GNSS receiver module from LOCOSYS. This module integrates a global navigation satellite system (GNSS) receiver with an on-board antenna, making it a complete solution for providing satellite-based position data (a “smart antenna”).

The LC20031-V2 outputs data at up to 10 Hz as NMEA sentences on a TTL-level serial port, or UART, and the module ships with a cable assembly that you can use to connect it to your project (either with a matching receptacle or by cutting off the connector to access the individual wire leads). A built-in rechargeable battery preserves system data while the module is inactive for rapid satellite acquisition on the next start-up.

Unlike GPS-only receivers such as the LS20031, the LC20031-V2 works with many different satellite systems. GPS, GLONASS, BeiDou, Galileo, and QZSS satellite signals are all supported, and the module can receive both L1 and L5 frequency band signals on up to 135 channels. This lets it achieve a typical position accuracy of 1.5 m CEP (circular error probable).

The GNSS Firebird software provided by LOCOSYS can be used to configure the LC20031-V2 and view its output. In this screenshot, you can easily see the different satellite systems that the receiver is tracking, represented by the different colors in the displays (GPS is blue, GLONASS is orange, Galileo is green, and BeiDou is red).

|

GNSS Firebird application showing data from an LC20031-V2 module inside Pololu’s offices. |

|---|

Introducing the 3pi+ 2040 Robot

I am super excited to introduce our newest robot, the 3pi+ 2040. This robot combines the 3pi+ chassis, which we initially released in late 2020, with the power of the Raspberry Pi RP2040 microcontroller. Here is a quick overview of its features:

|

|

This summer will mark 15 years since we released our original 3pi robot, which was designed to be fast enough to be competitive in line following and maze solving events. The high speed offers interesting programming challenges not present in typical robot kits of that era; here is a video from back then in which Ben demonstrates his 3pi learning a maze and then going extra fast on longer straightaways:

Although we developed our first injection-molded parts (wheels, ball caster, and motor mounting brackets) for that design, it was still largely a “PCB on wheels” kind of robot. The next-generation 3pi+, with a chassis mechanically independent of any circuit board, had been in development for several years when the coronavirus pandemic hit in early 2020. We kept working on it throughout that year, culminating with the November release of the 3pi+ 32U4.

|

|

The 3pi+ delivered the most-requested feature missing from the 3pi, wheel encoders, along with many other improvements including a full IMU, bumpers, and programmability over USB (the 3pi required an external AVR programmer). With its support in the Arduino environment, the ATmega32U4 continues to offer a good entry point for working with microcontrollers, but the 8-bit architecture and 32 KB of program memory feel increasingly outdated and constraining, especially with the new sensors available on the 3pi+.

That brings us to the new 3pi+ 2040, powered by the Raspberry Pi RP2040 microcontroller (32-bit dual-core Arm Cortex-M0+) with 16 MB (128 Mbit) of flash memory. The robot ships preloaded with a MicroPython interpreter, so you can get started right away by plugging into its USB C port and editing the included example Python programs with your favorite text editor. No special programmers or programming software are required, and you can write MicroPython code from practically any desktop or mobile operating system as long as it has a text editor and the ability to copy files to a USB drive. For a basic Python IDE that lets you run code interactively, we are recommending the Mu editor. (See the User’s Guide for instructions on setting it up.)

|

|

There are many other programming environments and languages that you can use with the 3pi+. Since it shares the same RP2040 processor as the Raspberry Pi Pico, anything that works for the Pico should be usable on the 3pi+, including C, C++, and the Arduino environment. We already include some basic C examples in our example code repository, and we plan to write more examples and expand the software support for this robot. Do you have a favorite IDE that works with the Pico? Is there some language or system you’d like to run on the 3pi+?

|

The menu of pre-installed demo programs on the 3pi+ 2040 Robot. |

|---|

Early adopter special: We are initially offering the 3pi+ 2040 Robot as a limited release intended for advanced customers who have had some experience with robotics or Raspberry Pi RP2040 programming (e.g. with a Raspberry Pi Pico). The initial release is available with 30:1 MP motors (the “Standard Edition”), either assembled for 38% off or in kit form for 50% off. Early adopter robots will generally need to be backordered as they are built to order; we expect to ship within a business day of ordering. The robot hardware is finalized so the only changes we expect for the full product release are in the initial firmware configuration and pre-installed example programs. Documentation will also continue to be developed as we release the robot to a wider customer base. Early adopters who publicly share their 3pi+ 2040 experiences will be eligible for an additional robot with an extra $25 discount.