Pololu Metal DC Gearmotors » 25D Metal Gearmotors » 12V Medium-Power (MP) 25D mm Gearmotors »

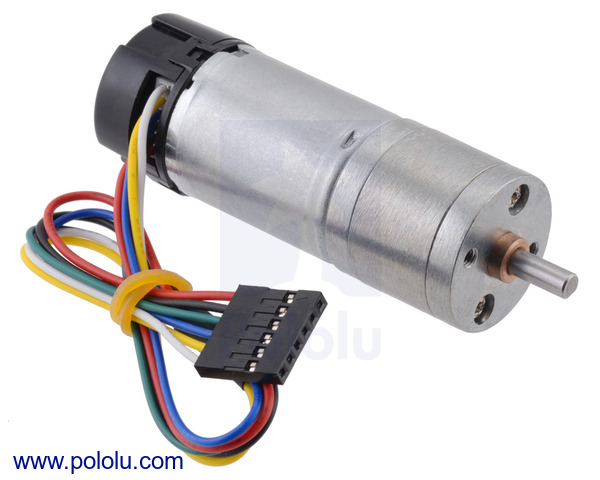

227:1 Metal Gearmotor 25Dx71L mm MP 12V with 48 CPR Encoder

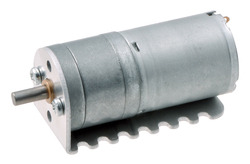

This gearmotor consists of a medium-power, 12 V brushed DC motor combined with a 226.76:1 metal spur gearbox, and it has an integrated 48 CPR quadrature encoder on the motor shaft, which provides 10,884.47 counts per revolution of the gearbox’s output shaft. The gearmotor is cylindrical, with a diameter just under 25 mm, and the D-shaped output shaft is 4 mm in diameter and extends 12.5 mm from the face plate of the gearbox. This gearmotor is also available without an encoder.

Key specifications:

| voltage | no-load performance | stall extrapolation |

|---|---|---|

| 12 V | 35 RPM, 100 mA | 24 kg⋅cm (330 oz⋅in), 1.8 A |

Alternatives available with variations in these parameter(s): gear ratio motor type encoders? Select variant…

Compare all products in 12V Medium-Power (MP) 25D mm Gearmotors.

Compare all products in 12V Medium-Power (MP) 25D mm Gearmotors.

| Description | Specs (19) | Pictures (11) | Resources (4) | FAQs (3) | On the blog (0) | Distributors (25) |

|---|

Overview

These cylindrical brushed DC gearmotors are available in a wide range of gear ratios and with five different motors (two power levels of 6 V motors and three power levels of 12 V motors). The gearmotors all have the same 25 mm diameter case and 4 mm diameter gearbox output shaft, so it is generally easy to swap one version for another if your design requirements change (though the length of the gearbox tends to increase with the gear ratio). The motor and encoder portion is available by itself (no gearbox) for each combination of power level and nominal operating voltage, and versions without the encoder are also available. See the 25D metal gearmotor datasheet (2MB pdf) for more information, including detailed performance graphs for each gearmotor version. You can also use our dynamically sortable 25D gearmotor comparison table to search for the version that offers the best combination of speed, torque, and current draw for your particular application. A more basic comparison table is available below.

| Rated Voltage |

Motor Type |

Stall Current |

No-Load Current |

Gear Ratio | No-Load Speed (RPM) |

Extrapolated Stall Torque |

Max Power (W) |

Without Encoder |

With Encoder |

|

|---|---|---|---|---|---|---|---|---|---|---|

| (kg ⋅ cm) | (oz ⋅ in) | |||||||||

| 12 V | High-Power (HP) |

5.0 A | 250 mA w/o encoder 300 mA with encoder |

1:1 (no gearbox) | 10,000 | 0.4 | 5.5 | 10 | – | item #4840 |

| 4.4:1 | 2200 | 1.7 | 24 | 9.4 | item #3201 | item #4841 | ||||

| 9.7:1 | 1000 | 3.9 | 54 | 10 | item #3202 | item #4842 | ||||

| 20.4:1 | 500 | 7.4 | 100 | 9.4 | item #3203 | item #4843 | ||||

| 34:1 | 300 | 11 | 150 | 8.9 | item #3204 | item #4844 | ||||

| 47:1 | 220 | 15 | 210 | 8.4 | item #3205 | item #4845 | ||||

| 75:1 | 130 | 22 | 310 | – | item #3206 | item #4846 | ||||

| 99:1 | 100 | 29 | 400 | – | item #3207 | item #4847 | ||||

| 12 V | Medium-Power (MP) |

1.8 A | 80 mA w/o encoder 100 mA with encoder |

1:1 (no gearbox) | 8200 | 0.17 | 2.4 | 3.5 | – | item #4860 |

| 4.4:1 | 1800 | 0.71 | 10 | 3.2 | item #3225 | item #4861 | ||||

| 9.7:1 | 800 | 1.7 | 24 | 3.4 | item #3226 | item #4862 | ||||

| 20.4:1 | 380 | 3.2 | 44 | 3.1 | item #3227 | item #4863 | ||||

| 34:1 | 230 | 4.7 | 65 | 2.8 | item #3228 | item #4864 | ||||

| 47:1 | 170 | 6.4 | 89 | 2.8 | item #3229 | item #4865 | ||||

| 75:1 | 100 | 8.5 | 120 | 2.3 | item #3230 | item #4866 | ||||

| 99:1 | 79 | 11 | 150 | 2.3 | item #3231 | item #4867 | ||||

| 172:1 | 46 | 18 | 250 | 2.1 | item #3232 | item #4868 | ||||

| 227:1 | 35 | 24 | 330 | – | item #3233 | item #4869 | ||||

| 12 V | Low-Power (LP) |

0.9 A | 50 mA w/o encoder 60 mA with encoder |

1:1 (no gearbox) | 5600 | 0.14 | 1.9 | 1.8 | – | item #4880 |

| 4.4:1 | 1200 | 0.53 | 7.4 | 1.7 | item #3249 | item #4881 | ||||

| 9.7:1 | 580 | 1.3 | 18 | 1.8 | item #3250 | item #4882 | ||||

| 20.4:1 | 280 | 2.4 | 33 | 1.7 | item #3251 | item #4883 | ||||

| 34:1 | 170 | 3.7 | 51 | 1.6 | item #3252 | item #4884 | ||||

| 47:1 | 120 | 4.8 | 67 | 1.4 | item #3253 | item #4885 | ||||

| 75:1 | 75 | 7.1 | 99 | 1.4 | item #3254 | item #4886 | ||||

| 99:1 | 57 | 8.7 | 120 | 1.2 | item #3255 | item #4887 | ||||

| 172:1 | 33 | 13 | 180 | 1.1 | item #3256 | item #4888 | ||||

| 227:1 | 25 | 16 | 220 | 1.0 | item #3257 | item #4889 | ||||

| 378:1 | 15 | 23 | 320 | – | item #3258 | item #4890 | ||||

| 6 V | High-Power (HP) |

6.0 A | 420 mA w/o encoder 500 mA with encoder |

1:1 (no gearbox) | 10,000 | 0.3 | 4 | 7 | – | item #4800 |

| 4.4:1 | 2200 | 1.2 | 17 | 6.7 | item #1570 | item #4801 | ||||

| 9.7:1 | 1000 | 2.3 | 32 | 5.9 | item #1571 | item #4802 | ||||

| 20.4:1 | 480 | 4.8 | 67 | 5.9 | item #1572 | item #4803 | ||||

| 34:1 | 290 | 6.8 | 94 | 5.1 | item #1573 | item #4804 | ||||

| 47:1 | 210 | 9.1 | 130 | 4.9 | item #1574 | item #4805 | ||||

| 75:1 | 130 | 14 | 190 | 4.5 | item #1575 | item #4806 | ||||

| 99:1 | 99 | 15 | 210 | 3.9 | item #1576 | item #4807 | ||||

| 172:1 | 57 | 27 | 380 | – | item #1577 | item #4808 | ||||

| 6 V | Low-Power (LP) |

2.0 A | 100 mA w/o encoder 120 mA with encoder |

1:1 (no gearbox) | 6200 | 0.15 | 2.1 | 2.1 | – | item #4820 |

| 4.4:1 | 1300 | 0.63 | 8.7 | 2.1 | item #1581 | item #4821 | ||||

| 9.7:1 | 630 | 1.3 | 18 | 1.9 | item #1582 | item #4822 | ||||

| 20.4:1 | 290 | 2.5 | 35 | 1.9 | item #1583 | item #4823 | ||||

| 34:1 | 180 | 3.9 | 54 | 1.7 | item #1584 | item #4824 | ||||

| 47:1 | 130 | 4.8 | 67 | 1.5 | item #1585 | item #4825 | ||||

| 75:1 | 80 | 7.5 | 100 | 1.5 | item #1586 | item #4826 | ||||

| 99:1 | 61 | 9.1 | 130 | 1.4 | item #1587 | item #4827 | ||||

| 172:1 | 35 | 14 | 190 | 1.2 | item #1588 | item #4828 | ||||

| 227:1 | 27 | 17 | 240 | 1.1 | item #1589 | item #4829 | ||||

| 378:1 | 16 | 25 | 350 | – | item #1590 | item #4830 | ||||

| 499:1 | 12 | 31 | 430 | – | item #1591 | item #4831 | ||||

Note: The listed stall torques and currents are theoretical extrapolations; units will typically stall well before these points as the motors heat up. Stalling or overloading gearmotors can greatly decrease their lifetimes and even result in immediate damage. The recommended upper limit for continuously applied loads is 4 kg⋅cm (55 oz⋅in), and the recommended upper limit for intermittently permissible torque is 8 kg⋅cm (110 oz⋅in). Stalls can also result in rapid (potentially on the order of seconds) thermal damage to the motor windings and brushes; a general recommendation for brushed DC motor operation is 25% or less of the stall current.

In general, these kinds of motors can run at voltages above and below their nominal voltages (they can begin rotating at voltages as low as 1 V); lower voltages might not be practical, and higher voltages could start negatively affecting the life of the motor.

These gearmotors are functionally identical to the previous versions we carried without end caps (they use the same motor, encoder, and gearboxes). The black plastic end cap is easily removable if you need to access the encoder or want to slightly reduce the overall gearmotor size, but there is a little bit of base plastic that will remain, as shown in the picture below:

|

Details for item #4869

Exact gear ratio: ``(22×22×22×22×22×22×24) / (12×10×10×10×10×10×10) ~~ bb(226.76:1)``

Dimensions

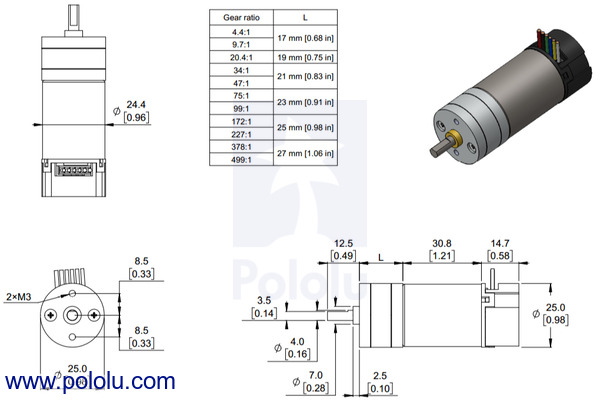

The diagram below shows the dimensions of the 25D mm line of gearmotors (units are mm over [inches]). This diagram is also available as a downloadable PDF (171k pdf).

|

Dimensions of the Pololu 25D mm metal gearmotors with encoders. Units are mm over [inches]. |

|---|

Warning: Do not screw too far into the mounting holes as the screws can hit the gears. We recommend screwing no further than 6 mm (0.24″) into the screw hole.

|

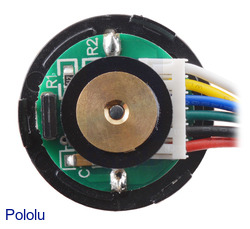

25D mm metal gearmotor with 48 CPR encoder (with end cap removed). |

|---|

|

Using the encoder

A two-channel Hall effect encoder is used to sense the rotation of a magnetic disk on a rear protrusion of the motor shaft. The quadrature encoder provides a resolution of 48 counts per revolution of the motor shaft when counting both edges of both channels. To compute the counts per revolution of the gearbox output, multiply the gear ratio by 48. The motor/encoder has six color-coded, 8″ (20 cm) leads terminated by a 1×6 female header with a 0.1″ pitch, as shown in the main product picture. This header works with standard 0.1″ male headers and our male jumper and precrimped wires. If this header is not convenient for your application, you can pull the crimped wires out of the header or cut the header off. The following table describes the wire functions:

| Color | Function |

|---|---|

| Red | motor power (connects to one motor terminal) |

| Black | motor power (connects to the other motor terminal) |

| Green | encoder GND |

| Blue | encoder Vcc (3.5 V to 20 V) |

| Yellow | encoder A output |

| White | encoder B output |

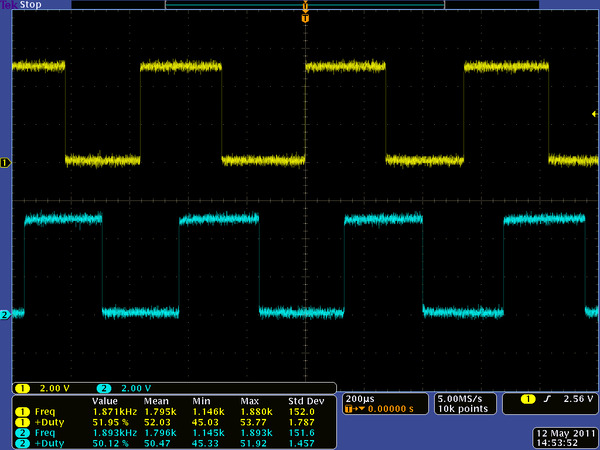

The Hall sensor requires an input voltage, Vcc, between 3.5 and 20 V and draws a maximum of 10 mA. The A and B outputs are square waves from 0 V to Vcc approximately 90° out of phase. The frequency of the transitions tells you the speed of the motor, and the order of the transitions tells you the direction. The following oscilloscope capture shows the A and B (yellow and white) encoder outputs using a motor voltage of 6 V and a Hall sensor Vcc of 5 V:

|

Encoder A and B outputs for 25D mm HP 6V metal gearmotor with 48 CPR encoder (motor running at 6 V). |

|---|

By counting both the rising and falling edges of both the A and B outputs, it is possible to get 48 counts per revolution of the motor shaft. Using just a single edge of one channel results in 12 counts per revolution of the motor shaft, so the frequency of the A output in the above oscilloscope capture is 12 times the motor rotation frequency.

Gearmotor accessories

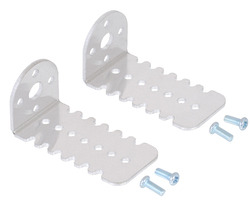

- Mounting brackets: The face plate has two mounting holes threaded for M3 screws. You can use our custom-designed 25D mm metal gearmotor bracket (shown in the picture below) to mount the gearmotor to your project via these mounting holes and the screws that come with the bracket.

|

|

- Wheels and hubs: The 4 mm diameter gearbox output shaft works with Pololu multi-hub wheels as shown in the left picture below. That shaft also works with the Pololu universal aluminum mounting hub for 4mm shafts, which can be used to mount our larger Pololu wheels (60mm-, 70mm-, 80mm-, and 90mm-diameter) or custom wheels and mechanisms to the gearmotor’s output shaft as shown in the right picture below.

|

|

Alternatively, you could use our 4mm scooter wheel adapter to mount many common scooter, skateboard, and inline skate wheels to the gearmotor’s output shaft as shown in the left picture below. For a general-purpose hex adapter, consider our 12mm hex wheel adapter, which lets you use this motor with many common hobby RC wheels as shown in the right picture below.

|

|

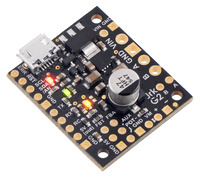

- Motor controllers and drivers: We have a number of motor drivers and motor controllers that work with these 25D mm metal gearmotors. For the LP and MP versions, we recommend our TB9051FTG-based drivers, for which we have a basic single carrier, a dual-channel shield for Arduino, and a dual-channel expansion board for Raspberry Pi. For the HP versions, we recommend our VNH5019-based motor drivers (available as single and dual carriers), though these can also be a good choice for the lower-power motors.

|

|

If you are looking for higher-level control interfaces, such as USB, RC, analog voltages, I²C, or TTL serial, consider our Motoron motor controllers, Jrk motor controllers, or RoboClaw motor controllers; these controllers are available in various power levels several of which can handle the 25D mm metal gearmotors (we generally recommend a motor controller that can handle continuous currents above the stall current of your motor).

|

Three Motoron M3H550 controllers being controlled by a Raspberry Pi. |

|---|

|

Jrk G2 21v3 USB Motor Controller with Feedback. |

|---|

|

RoboClaw 2×7A Motor Controller (V5B) in its included case. |

|---|

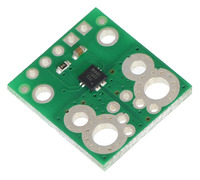

- Current sensors: We have an assortment of current sensors to choose from for those who need to monitor motor current:

|

|

Selecting the right gearmotor

We offer a wide selection of metal gearmotors that offer different combinations of speed and torque. Our metal gearmotor comparison table can help you find the motor that best meets your project’s requirements.

|

People often buy this product together with:

|

Pololu Universal Aluminum Mounting Hub for 4mm Shaft, #4-40 Holes (2-Pack) |

|

Pololu Universal Aluminum Mounting Hub for 4mm Shaft, M3 Holes (2-Pack) |

|

Pololu 25D mm Metal Gearmotor Bracket Pair |