Mini Plastic Gearmotors »

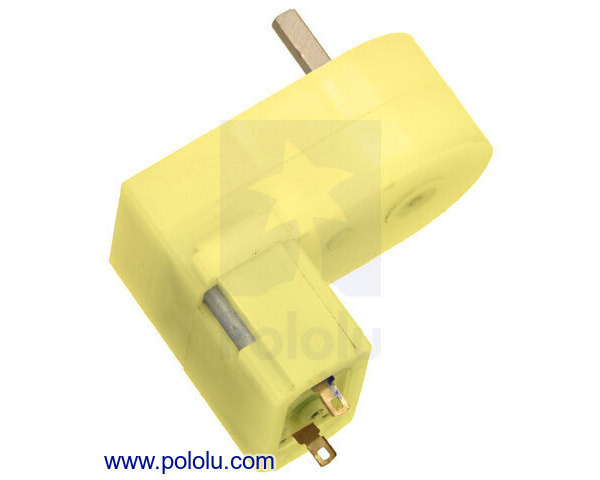

180:1 Mini Plastic Gearmotor, Offset 3mm D-Shaft Output

This compact, inexpensive plastic gearmotor (brushed DC motor with a 180:1 reduction gearbox) is well suited for use in small robots. While intended for operation at 4.5 V, it should run comfortably in the 3 V to 6 V range. The gearbox has a 9.7mm-long, 3 mm-diameter D-shaped output shaft that is offset from but parallel to the motor shaft, and a built-in safety clutch helps protect the gears from excessive loads.

Key specifications:

| voltage | no-load performance | stall extrapolation |

|---|---|---|

| 4.5 V | 80 RPM, 80 mA | 2.2 kg⋅cm (30 oz⋅in), 800 mA |

Alternatives available with variations in these parameter(s): shaft type no-load speed @ 4.5V extended motor shaft? Select variant…

| Description | Specs (11) | Pictures (13) | Resources (7) | FAQs (1) | On the blog (1) | Distributors (0) |

|---|

File downloads

-

dimension diagram: 90° 3mm D-shaft version (75k pdf)

Dimension diagram of the mini plastic gearmotor with 90° 3mm D-shaft output.

-

dimension diagram: 90° 3mm D-shaft and extended motor shaft version (70k pdf)

Dimension diagram of the mini plastic gearmotor with 90° 3mm D-shaft output and extended motor shaft.

-

dimension diagram: 90° 3mm D-shaft and extended motor shaft version HP (70k pdf)

Dimension diagram of the mini plastic gearmotor HP with 90° 3mm D-shaft output and extended motor shaft.

-

dimension diagram: offset 3mm D-shaft version (77k pdf)

Dimension diagram of the mini plastic gearmotor with offset 3mm D-shaft output.

-

dimension diagram: offset 3mm D-shaft and extended motor shaft version (69k pdf)

Dimension diagram of the mini plastic gearmotor with offset 3mm D-shaft output and extended motor shaft.

-

dimension diagram: offset 3mm D-shaft and extended motor shaft version HP (69k pdf)

Dimension diagram of the mini plastic gearmotor HP with offset 3mm D-shaft output and extended motor shaft.

Recommended links

-

MATLAB script to plot motor performance curves for Pololu brushed DC gearmotors

This MATLAB script, written by Ali Asgher Mansoor Habiby, plots speed, power, current draw, and efficiency as they vary with torque when you input the gearmotor specifications. It also prints the resistance of the motor, and the current draw and torque at which maximum efficiency and maximum power occur.