Overview

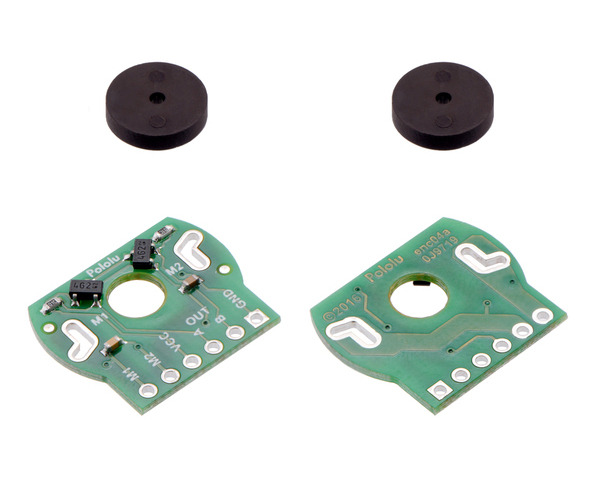

This kit includes two dual-channel Hall effect sensor boards and two 6-pole magnetic discs that can be used to add quadrature encoding to two mini plastic gearmotors with extended back shafts (motors are not included with this kit). The encoder board senses the rotation of the magnetic disc and provides a resolution of 12 counts per revolution of the motor shaft when counting both edges of both channels. To compute the counts per revolution of the gearbox output shaft, multiply the gear ratio by 12.

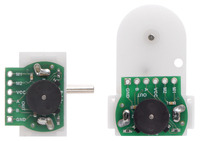

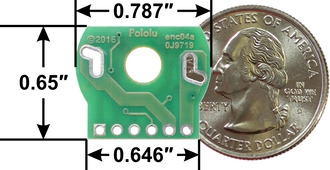

This compact encoder solution fits within the 11.5 mm × 22.5 mm cross section of the rear of the motors on three of the four sides. The fourth side of the encoder has the signal and power connections, and it extends 5 mm past the edge of the motor to leave room for mounting brackets. The assembly does not extend past the end of the extended motor shaft, which protrudes 5 mm beyond the back of the motor.

Note: This sensor system is intended for users comfortable with the physical encoder installation. It only works with mini plastic gearmotors that have extended motor shafts.

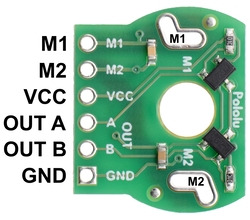

Pinout and installation

The encoder board is designed to be soldered directly to the back of the motor, with the back shaft of the motor protruding through the hole in the middle of the circuit board. One way to achieve good alignment between the board and the motor is to tack down the board to one motor pin and to solder the other pin only when the board is flat and well aligned. Be careful to avoid prolonged heating of the motor pins, which could deform the motor case or brushes. Once the board is soldered down to the two terminals, the motor leads are connected to the M1 and M2 pads along the edge of the board; the remaining four pads are used to power the sensors and access the two quadrature outputs:

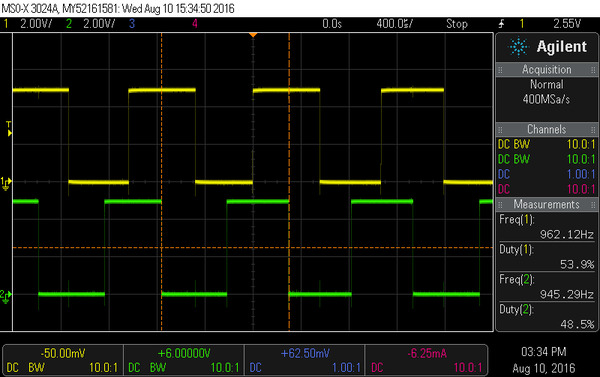

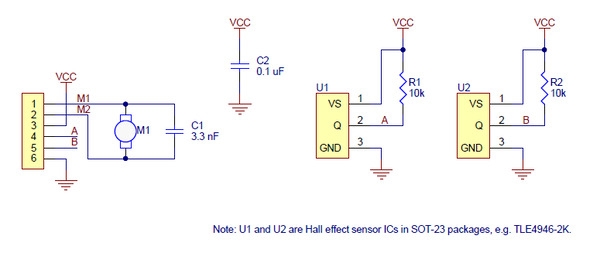

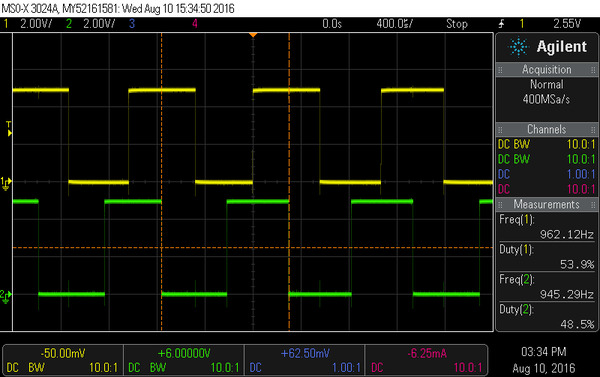

The sensors are powered through the VCC and GND pins. VCC can be 2.7 V to 18 V, and the quadrature outputs A and B are digital signals that are either driven low (0 V) by the sensors or pulled to VCC through 10 kΩ pull-up resistors, depending on the applied magnetic field. The sensors’ comparators have built-in hysteresis, which prevents spurious signals in cases where the motor stops near a transition point.

|

Encoder A and B outputs of a magnetic encoder on a high-power (HP) mini plastic gearmotor running at 4.5 V. |

|---|

The board’s six pads have a 0.1″ (2.54 mm) pitch, so they are compatible with common 0.1″ connectors, or you can just solder individual wires directly to the board.

Once the board is soldered to the motor, the magnetic encoder disc can be pushed onto the motor shaft. One easy way to accomplish this is to press the motor onto the disc while it is sitting on a flat surface, pushing until the shaft makes contact with that surface. The size of the gap between the encoder disc and the sensor board does not have a big impact on performance as long as the motor shaft is at least all the way through the disc.

Schematic diagram

This schematic is also available as a downloadable pdf (77k pdf).

People often buy this product together with: