Pololu Metal DC Gearmotors » Micro Metal Gearmotors » Micro Metal Gearmotors with Extended Motor Shafts »

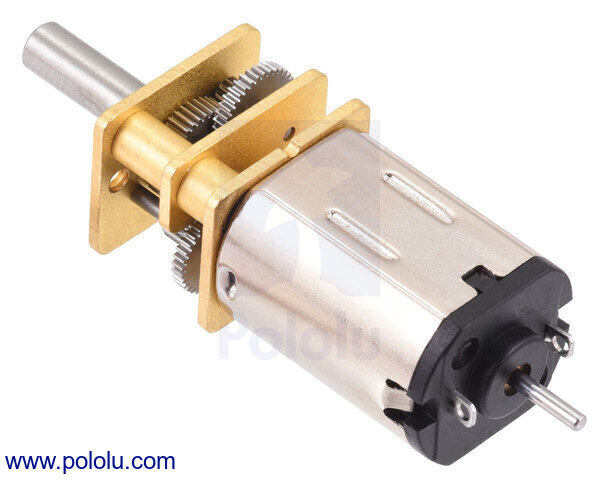

100:1 Micro Metal Gearmotor MP 6V with Extended Motor Shaft

This is a miniature brushed DC metal gearmotor with a gearbox cross section of 10×12 mm and a 9 mm long, 3 mm diameter D-shaped gearbox output shaft.

| motor/brush type | gearbox | encoder | |

|---|---|---|---|

| MP 6V: medium-power 6V with precious metal brushes | 100.37:1 with brass plates | encoder-compatible (extended motor shaft) | |

| voltage | no-load performance | stall extrapolation* |

|---|---|---|

| 6 V | 220 RPM, 70 mA | 0.94 kg⋅cm (13 oz⋅in), 0.67 A |

| * Note: Stall torque and stall current specifications are theoretical values; stalls could damage the motor or gearbox. | ||

Alternatives available with variations in these parameter(s): gear ratio motor type encoder Select variant…

Compare all products in Micro Metal Gearmotors with Extended Motor Shafts or

Compare all products in Micro Metal Gearmotors with Extended Motor Shafts or  6V Medium-Power (MP) Micro Metal Gearmotors.

6V Medium-Power (MP) Micro Metal Gearmotors.

| Description | Specs (16) | Pictures (17) | Resources (3) | FAQs (2) | On the blog (1) | Distributors (24) |

|---|

- Is it okay to stall this motor at its operating voltage?

No! Stalls can result in rapid (potentially on the order of seconds) thermal damage to the motor windings and brushes; a general recommendation for brushed DC motor operation is 25% or less of the stall current, which means keeping continuously applied loads around 25% or less of the stall torque.

Additionally, for many of our gearmotors with high gear ratios, the extrapolated stall torque is beyond what the gearboxes are designed to handle, and a stall could instantly damage the gears. Make sure to keep applied loads within the published limits for your gearmotor.

- What do the dotted lines mean in the motor performance curves from the datasheet?

- In our motor performance curves, the solid lines show the regions where we actually took measurements while the dotted lines show extrapolations beyond that. For many motors, we took measurements out to about 50% of the stall torque, since continued operation at loads past this point increasingly risk thermal damage to the windings. However, for higher gear ratios, going to 50% of the stall torque exceeds what is safe for the gearbox, so the measurements are further limited to not much past our recommendation for continuously applied loads.