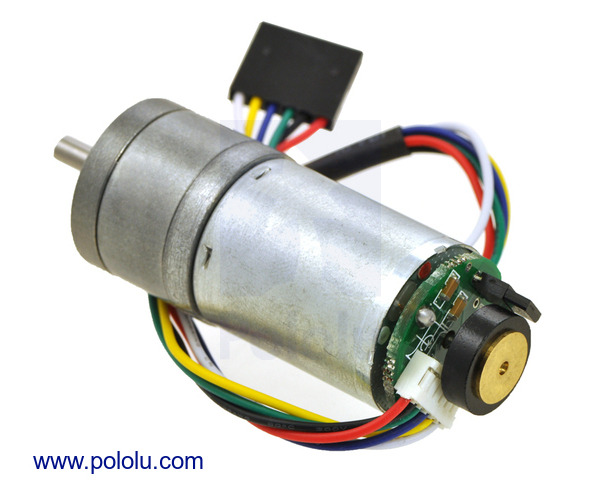

172:1 Metal Gearmotor 25Dx68L mm LP 6V with 48 CPR Encoder (No End Cap)

Clearance: This is being replaced by a functionally identical version that has a removable protective end cap over the encoder.

This gearmotor consists of a low-power, 6 V brushed DC motor combined with a 171.79:1 metal spur gearbox, and it has an integrated 48 CPR quadrature encoder on the motor shaft, which provides 8245.92 counts per revolution of the gearbox’s output shaft. The gearmotor is cylindrical, with a diameter just under 25 mm, and the D-shaped output shaft is 4 mm in diameter and extends 12.5 mm from the face plate of the gearbox.

Key specifications:

| voltage | no-load performance | stall extrapolation |

|---|---|---|

| 6 V | 34 RPM, 250 mA | 14.5 kg⋅cm (200 oz⋅in), 2.4 A |

You can use the following selection boxes to choose from all of our 25D metal gearmotor versions:

Alternatives available with variations in these parameter(s): gear ratio motor type encoders? Select variant…

| Description | Specs (11) | Pictures (14) | Resources (4) | FAQs (2) | On the blog (0) | Distributors (0) |

|---|

File downloads

-

Dimension diagram of Pololu 25D mm Metal Gearmotors (223k pdf)

-

3D models of 25D mm gearmotors (9MB zip)

This file contains 3D models (in the step file format) of the 25D mm gearmotors with and without encoders.

-

Modifying the Wild Thumper to use motors with encoders (3MB pdf)

Customer Richard Nguyen has documented his work modifying the Wild Thumper chassis to use 25D motors with encoders in place of the chassis’s included motors.

Note: This is not an easy modification, and the chassis can be damaged if it is not done properly, so we generally recommend against it, and we can only provide very limited support for those who want to attempt it. The manufacturer did not intend for the chassis to be modified in this way, and we do not know how well such a modification will work out.

Recommended links

-

MATLAB script to plot motor performance curves for Pololu brushed DC gearmotors

This MATLAB script, written by Ali Asgher Mansoor Habiby, plots speed, power, current draw, and efficiency as they vary with torque when you input the gearmotor specifications. It also prints the resistance of the motor, and the current draw and torque at which maximum efficiency and maximum power occur.