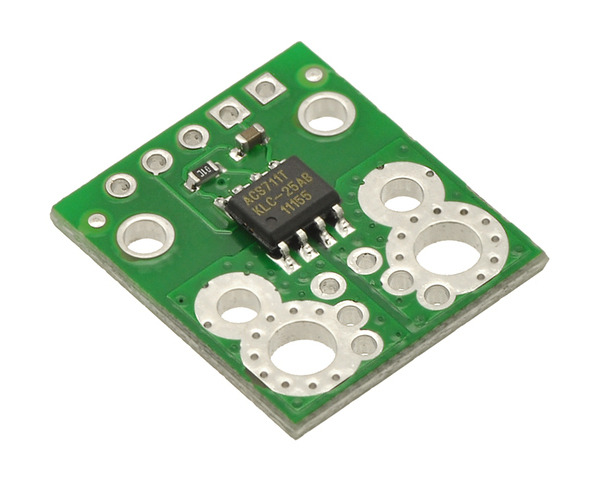

ACS711LC Current Sensor Carrier -12.5A to +12.5A

This board is a simple carrier of Allegro’s ±12.5A ACS711 Hall effect-based linear current sensor with overcurrent fault output, which offers a low-resistance (~1.2 mΩ) current path and electrical isolation up to 100 V. This version accepts a bidirectional current input with a magnitude up to 12.5 A and outputs a proportional analog voltage centered at Vcc/2 with a typical error of ±5%. It operates from 3 V to 5.5 V, so it can interface directly to both 3.3 V and 5 V systems.

| Description | Specs (6) | Pictures (6) | Resources (1) | FAQs (0) | On the blog (0) | Distributors (0) |

|---|

Discontinuation notice: This sensor has been replaced by the ACS711EX current sensor carrier -15.5A to +15.5A, which features the newer “EX” IC package with a larger optimized sensing range and reduced internal resistance. The new version has the same board size, pinout, and hole locations, so it can generally be used as a drop-in replacement for this original “LC”-package version.

Overview

|

|

This current sensor is a carrier board or breakout board for Allegro’s ACS711KLCTR-12AB-T Hall effect-based linear current sensor with overcurrent fault output; we therefore recommend careful reading of the ACS711 datasheet (533k pdf) before using this product. The sensor has an operating voltage of 3 V to 5.5 V and an output sensitivity of 110 mV/A when Vcc is 3.3 V (or 167 mV/A when Vcc is 5 V). The following list details some of the sensor’s key features:

- Designed for bidirectional input current from -12.5 A to 12.5 A (though the robust sensor IC can survive up to five times the overcurrent condition).

- Conductive path internal resistance is typically 1.2 mΩ, and the PCB is made with 2-oz copper, so very little power is lost in the board.

- Use of a Hall effect sensor means the IC is able to electrically isolate the current path from the sensor’s electronics (for applications up to 100 V), which allows the sensor to be inserted anywhere along the current path and to be used in applications that require electrical isolation.

- 100 kHz bandwidth.

- Good accuracy and reliability: factory calibration results in a typical total output error of ±5% at room temperature, the output offset voltage is extremely stable, and the sensor has zero magnetic hysteresis.

- Overcurrent FAULT output latches low when current magnitude exceeds 12.5 A.

- Operating temperature range of -40°C to 125°C.

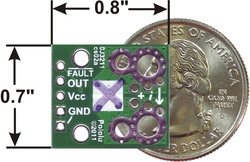

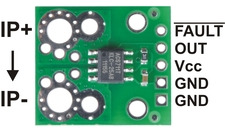

The pads are labeled on the bottom silkscreen, as shown in the picture to the right. The silkscreen also shows the direction that is interpreted as positive current flow via the +i arrow.

This 12.5 A current sensor is marked with a purple X. We also sell a 25 A version that uses the same carrier PCB; you can distinguish the versions by reading the text on the IC or by looking at the color of the X on the bottom silkscreen.

Using the sensor

Electrical connections

The sensor requires a supply voltage of 3 to 5.5 V to be connected across the Vcc and GND pads, which are labeled on the bottom silkscreen. The sensor outputs an analog voltage that is linearly proportional to the input current. The quiescent output voltage is Vcc/2 and changes by 110 mV per amp of input current (when Vcc = 3.3 V), with positive current increasing the output voltage and negative current decreasing the output voltage. For an arbitrary input current i (in amps), the sensor’s output voltage can be more generally represented as:

VOUT = (0.11 V/A * i + 1.65 V) * Vcc / 3.3 V

The FAULT pin is normally high and latches low when the current exceeds ±12.5 A. Once the FAULT pin is latched low, the only way to reset it is by toggling power on the Vcc pin.

|

|

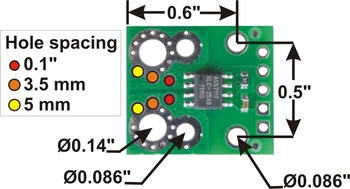

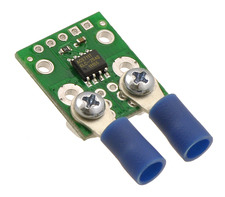

The input current can be connected to the board in a variety of ways. Holes with 0.1″, 3.5 mm, and 5 mm spacing are available as shown in the diagram above for connecting male header pins or terminal blocks. For high-current applications, you can solder wires directly to the through-holes that best match your wires, or you can use solderless ring terminal connectors, as shown in the picture above. The large through-holes are big enough for #6 screws.

Warning: This product is intended for use below 30 V. Working with higher voltages can be extremely dangerous and should only be attempted by qualified individuals with appropriate equipment and protective gear.

Mounting information

The board has two mounting holes on the logic side of the board. These mounting holes are 0.5" apart and are designed for #2 screws.

Included components

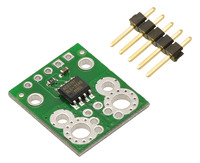

This board ships assembled with all surface mount components, and a 5×1 strip of 0.1″ header pins is included but not soldered in, as shown in the picture below.

|

ACS711LC current sensor carrier with included 5 × 1 0.1″ header pins. |

|---|

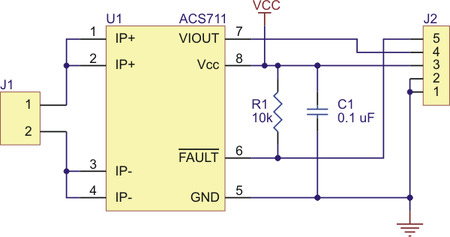

Schematic diagram

|

ACS711 current sensor carrier schematic diagram. |

|---|

People often buy this product together with:

|

0.1" (2.54mm) Crimp Connector Housing: 1x2-Pin 25-Pack |

|

0.1" (2.54mm) Crimp Connector Housing: 1x3-Pin 25-Pack |

|

ACS709 Current Sensor Carrier -75A to +75A |