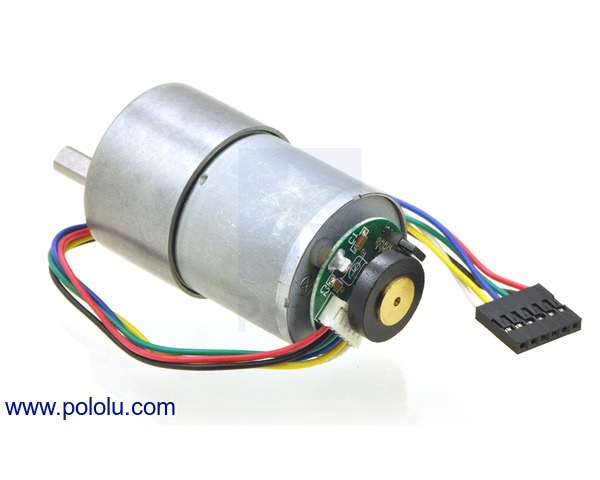

19:1 Metal Gearmotor 37Dx52L mm 12V with 64 CPR Encoder (No End Cap)

Note: This gearmotor has been replaced by a functionally identical version with a protective end cap over the encoder.

This gearmotor is a powerful 12V brushed DC motor with a 18.75:1 metal gearbox and an integrated quadrature encoder that provides a resolution of 64 counts per revolution of the motor shaft, which corresponds to 1200 counts per revolution of the gearbox’s output shaft. These units have a 0.61"-long, 6 mm-diameter D-shaped output shaft. This gearmotor is also available without an encoder.

Key specs at 12 V: 500 RPM and 300 mA free-run, 84 oz-in (5 kg-cm) and 5 A stall.

Alternatives available with variations in these parameter(s): gear ratio Select variant…

| Description | Specs (13) | Pictures (8) | Resources (1) | FAQs (2) | On the blog (0) | Distributors (0) |

|---|

- What material is the gearbox output shaft made of, and can I get the shaft customized?

- The shaft is composed of hardened stainless steel. Some customization is generally possible (e.g., different length or no D-shaft) for sufficiently high-volume orders. If this is something you are interested in, please email us.

- I need additional information about this motor; do you have a datasheet?

No; the information we have available for this motor can be found on its product page. However, you can approximate various additional motor parameters from the information found in the “Specs” tab.

The electrical resistance of the motor can be approximated by dividing the rated voltage by the stall current (at the rated voltage). The electromotive force constant (Ke) can be approximated by dividing the rated voltage by the free-run speed (at the rated voltage). To approximate the motor torque constant (Kt), you can divide the stall torque by the stall current.

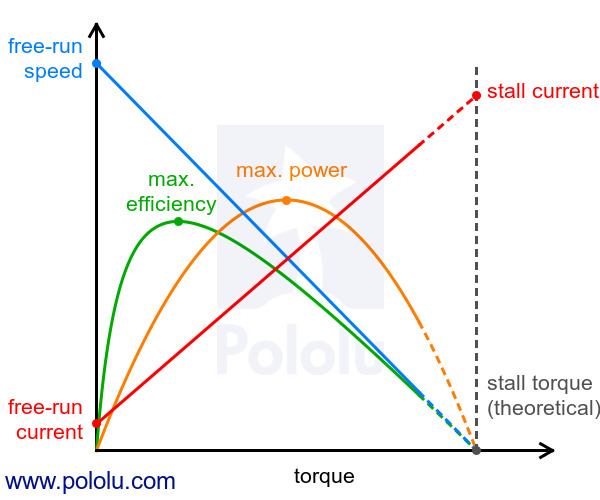

For pretty much any DC motor, the current, speed, power, and efficiency curves as a function of torque will look like those in the graph below (assuming motor voltage and temperature are constant):

The current and speed curves are approximately linear, and the product pages for our motors provide the approximate end points for these lines: (0 torque, no-load current) and (stall torque, stall current) for the red line, and (0 torque, no-load speed) and (stall torque, 0 speed) for the blue line.

The orange output power curve is the product of the speed and the torque, which results in an inverted parabola with its peak at 50% of the stall torque.

The green efficiency curve is the output power divided by the input power, where the input power is current times voltage. The voltage is constant, so you can divide the output power curve by the current line to get the general shape of the efficiency curve, which in turn lets you identify the torque, speed, and current that correspond to max efficiency.

There are many programs out there that you can use to generate these curves. For example, if you have access to MATLAB, you can use this customer-created MATLAB script to generate these motor plots for you from the specifications we provide for each gearmotor.

Note: A good general rule of thumb is to keep the continuous load on a DC motor from exceeding approximately 20% to 30% of the stall torque. Stalling gearmotors can greatly decrease their lifetimes, occasionally resulting in immediate damage to the gearbox or thermal damage to the motor windings or brushes. Do not expect to be able to safely operate a brushed DC gearmotor all the way to stall. The safe operating range will depend on the specifics of the gearmotor itself.