Support » Custom Laser Cutting Guide »

6. UV printing

|

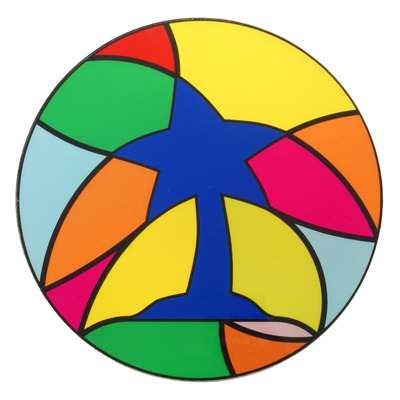

Laser-cut and UV-printed acrylic. |

|---|

Our UV Printing service – also commonly referred to as Flatbed Printing – is a great way to add vibrant and colorful labels, logos, photos, and artwork to your laser-cut parts. We use UV-cured ink that dries instantly, allowing us to offer fast turnarounds and affordable prices.

We can:

- Print directly onto a part or part layout up to 24″ × 16.5″ (61 cm × 42 cm).

- Print onto many of the materials we can laser cut.

- Print in 600 DPI or 1200 DPI resolution.

- Stack multiple layers of UV-cured ink to meet all of your project’s needs.

- Full-color CMYK ink (cyan, magenta, yellow, black)

- White ink creates a solid, opaque background for printing vibrant colors on non-white materials

- Primer ink improves ink adhesion strength making prints robust across a wide range of materials, even for low surface area prints

- Clear ink on top adds a layer of protection

- Print using vector objects, bitmap images, or both.

- Add a photo (JPG, PNG, TIF, etc) to your laser cut design for you.

Pricing

We quote custom laser cutting and UV printing simultaneously, so the prices in your quote are for both. Here are some of the factors that affect UV-printing prices:

- UV-printing set-up fee: We charge $50 per unique UV-printing layout.

- We reduce the setup fee for repeat orders.

- UV-printing cost: We quote UV-printed designs based on layout size, number of ink layers, and printing resolution.

- Typical, 600 DPI resolution four-layer prints (primer, white, color, clear) start around $15 per square foot (plus setup fees).

- High-resolution four-layer prints (600 DPI primer, 1200 DPI white, 1200 DPI color, 600 DPI clear) start around $25 per square foot (plus setup fees).

- File creation: If you have common picture files (JPG, PNG, TIF, etc), but are unable to incorporate them in your laser cutting vector or CAD files, we might be able to create a file for you. Our file creation service costs $60 per hour, with a $15 minimum.

As with typical laser cutting orders, we discount rates for volume orders and offer expedited options. See Section 2 for more general information about prices for custom laser cutting.

Limitations to consider

- While we can print onto many common laser cutting materials, we cannot print onto all of the materials we can laser cut.

- To check what materials we can and cannot print onto, please see Section 5.

- Our inks work best on rigid materials, and the prints do not hold up well to being bent or stretched.

- Ink adhesion strength depends on the material, whether primer is used, and the size/geometry of the artwork.

- We typically expect the alignment between printed artwork and laser cut geometry to be around 0.010″ (0.25 mm), but we do not guarantee any particular tolerance.

- For designs where it is important for artwork to go all the way to the part edge we recommend including at least a 0.020″ (0.5 mm) bleed past the cut lines, but please note that this might result in some ink getting along the side edges of the part.

- We decide whether to print before or after laser cutting on a case-by-case basis. If you have specific needs or concerns, please mention them when you submit your quote request.