Support » Custom Laser Cutting Guide »

5. Materials

We can laser cut plastics, woods, metals, rubbers, foams, and papers. We can handle some materials up to 1" thick, but the maximum thickness varies depending on the material. We stock some materials including acrylic, birch plywood, MDF, mild and stainless steel, aluminum, ABS, Delrin, and more. For a complete list of the materials we stock, and available thicknesses and colors, see our quote request form. You are also welcome to supply your own material for us to cut.

Materials we can laser cut

Here is a list of the materials that we can cut. If you do not see your material listed, we would be happy to try cutting it as long as it does not contain vinyl. To test a new material, please submit a quote request and provide details about your material in the special instructions section of the quote request form.

| Type | Material | Max Thickness | UV-printable | Notes |

|---|---|---|---|---|

| Plastics | ABS | 1/4″ | ✓ | Smells very bad when cut, so you might have to wash or air out the parts out upon receiving them to get rid of the smell. It is machine-friendly and will not break or crack easily if dropped or hit. It has a hair-cell textured front surface, which hides fingerprints and scuffs well. The backside of the material is smooth and glossy, and since ABS does not come with masking, this surface is prone to scratches and markings. |

| Acetal/Delrin | 1/4″ | ✘ | Has smooth, glossy surfaces that often have scratches on them. Delrin is a very tough, slippery material that resists warping and deforming well and is commonly used to make gears. Its slick surface makes it difficult to adhere to without sanding, so we cannot UV-print onto it. It is the most expensive plastic that we carry. | |

| Acrylic | 1″ | ✓ | Also known as Plexiglas, Lucite, PMMA. Our favorite material to work with – cuts cleanly with a laser-polished edge. See the More information about acrylicsection for more details. |

|

| HDPE | 1/16″ | ✘ | Edges melt badly and produce a lot of dust that sticks to the parts when cut. | |

| Kapton | 0.050″ | ✘ | Chars badly when cut, cutting adhesive-backed sheets increases the charring, and also causes the parts to be sticky. | |

| Mylar | 0.010″ | ✘ | Also known as Polyester film. | |

| Nylon | 1/16″ | ✘ | Edges melt, smell, and discolor badly when cut. | |

| PETG | 1/8″ | ✓ | Smells very bad when cut, so you might have to wash or air out the parts out upon receiving them to get rid of the smell. PETG is not brittle, so parts do not crack or break easily. PETG comes with a film masking on both sides to protect the surface during the cutting process, but the edges still tend to melt and turn yellow from the laser cutting. | |

| Polyethylene | 1/8″ | ✘ | Melts badly when cut. | |

| Polypropylene | 1/8″ | ✘ | Melts somewhat when cut | |

| Styrene | 1/8″ | ✓ | Smells very bad when cut, so you might have to wash or air out the parts out upon receiving them to get rid of the smell. Edges melt somewhat. | |

| Teflon | 1/8″ | ✘ | Melts somewhat when cut. | |

| Metals | Aluminum | 1/4″ | ✓ | Blemishes and light scratches may affect the surfaces of metal parts. Laser cutting metals may cause slight discoloration, dross formation, and burring. Typically, burring is minimal for metals under 1/8″ thick, but is more severe for thicker pieces. We do not offer any post-cutting services such as deburring, tumbling, polishing, bending, welding, anodizing, or coating (other than UV printing). We ship parts as cut. |

| Brass | 1/8″ | ✓ | ||

| Bronze | 1/8″ | ✓ | ||

| Mild Steel | 1/4″ | ✓ | ||

| Spring Steel | 1/4″ | ✓ | ||

| Stainless Steel | 1/4″ | ✓ | ||

| Woods | Birch Ply | 1″ | ✓ | A popular, eco-friendly plywood that is great for laser cutting. It is typically cut without masking, but can be masked to minimize burn markings for an additional fee. |

| MDF | 1″ | ✓ | Low-cost material to laser cut. Does not come with protective masking, so surfaces will have some discolorations and burn markings from cutting. | |

| Rubbers | NBR (Buna-N) | 3/32″ | ✘ | Laser cutting rubbers typically generates a lot of char/soot. We ship parts as cut without dusting or cleaning them. |

| FKM/Viton | 1/8″ | ✘ | ||

| Neoprene | 1/16″ | ✘ | ||

| Polyethylene | 1/8″ | ✘ | ||

| Silicone | 1/8″ | ✘ | ||

| Foams | Depron | 1″ | ✓ | Laser cutting foams typically generates some light char/soot around part edges. We ship parts as cut without dusting or cleaning them. The edges typically have a concave profile after cutting. How deep the concave shape extends depends on several factors, but a good way to prevent problems is to avoid having areas that are narrower than the thickness of the material. |

| EPDM | 1″ | ✘ | ||

| Neoprene | 1″ | ✘ | ||

| Nylon | 1″ | ✘ | ||

| Polyethylene | 1″ | ✘ | ||

| Polyurethane | 1″ | ✘ | ||

| Silicone | 1/8″ | ✘ | ||

| Others | Cardboard | 5/32″ | ✓ | Has a slight smell to it when laser cut. |

| Cardstock / Paper | ✓ | Can be laser cut, but it is usually more cost-effective to plot/die cut it instead. Edges might show light burn marks, depending on the material color (dark colors hide the markings better). | ||

| Fabrics | ✘ | We have cut various types of fabrics including acrylic, canvas, cordura, cotton, nylon, polyester, and wool, and have not had any trouble. Edges become cauterized (which helps prevent the fabric from fraying), but might have slight discoloration depending on the color. | ||

| Leather | 1/8″ | ✘ | All leather (both natural and synthetic) smells very bad when laser cut, so you might have to air the parts out once you receive them. Synthetic leather MUST be vinyl-free. Edges will have noticeable char/soot on them. |

Materials we cannot laser cut

We do not or cannot cut the following materials:

| Material | Notes |

|---|---|

| ✘ Carbon Fiber | |

| ✘ Copper | For copper parts, or other metals that are not included in the list of we metals we can cut, please consider our friends at OSH Cut. |

| ✘ Glass | |

| ✘ PCB | We cannot cut printed circuit board materials such as FR-4, G-10 (garolite), and others. |

| ✘ Polycarbonate | Difficult to laser cut, and burns very badly. Consider PETG or impact-modified acrylic instead. |

| ✘ PVC | Also commonly known as Cintra – contains vinyl, which releases toxic fumes. |

| ✘ Vinyl | We do not cut any materials that contain vinyl since it releases toxic fumes. |

How to supply your own material for laser cutting

If you plan to supply material the material for your order, please mention this in the special instructions section in our quote request form and be sure to include the sheet size. When sending material:

- Please wait until after you have received your quote before you ship it (in case we cannot cut that material, or your design, etc.).

- Make sure to include your name and quote number with the shipment.

- Make sure the material is flat, as warped or bowed materials can cause problems during cutting. Some materials, like rubbers and fabrics, can be shipped rolled since they will still lay flat right away, while others can take a very long time to flatten out.

- Do not ship material that is longer than 48″ unless it can be cut down using scissors or you have made special arrangements with us for larger pieces.

- You can have suppliers ship directly to us to avoid having to pay an extra shipping charge.

- You are responsible for supplying any extra material needed to recut parts that do not come out well (we cover this when using our stock material).

- Please let us know what you would like us to do with the leftover material. We can hold it for another order in the near future, discard it, or send it to you along with your order (an additional shipping charge might be required).

Suppliers for laser-cutting materials

Here is a list of suppliers we and our customers work with frequently:

- McMaster-Carr — Highly-recommended for expedited laser-cutting orders – they ship fast!

- Delvie’s Plastics

- Johnson Plastics Plus — Large selection of two-tone “engravable” acrylics.

- TAP Plastics

- Online Metals

- Inventables

- ePlastics

- Professional Plastics

- eStreet Plastics

- United States Plastics

Laser material details

Plastics

ABS (acrylonitrile butadiene styrene)

| Max thickness | 1/4″ (6.4 mm) |

|---|---|

| UV-printable | ✓ |

| Primer recommended for UV printing |

✓ |

| Stocked | ✓ |

| RoHS 3 | ✘ |

| Stocked thicknesses | 1.5 mm (0.06″) 3.0 mm (0.12″) 4.5 mm (0.18″) 6.0 mm (0.24″) |

| Stocked layout sizes | 12″×12″ (30×30 cm) 12″×24″ (30×61 cm) 24″×24″ (61×61 cm) 24″×48″ (61×122 cm) 32″×48″ (81×122 cm) |

| Stocked colors | black |

| Masking | added on request |

| Surface texture | haircell and smooth (see notes) |

| Surface finish | glossy (see notes) |

| Opacity | opaque |

Notes:

- ABS has good elasticity and toughness, so it can bend a lot before cracking or breaking, and it will not crack or break easily if dropped or impacted.

- It is easily machined with hand tools.

- Our stocked ABS has a haircell textured front surface, which hides fingerprints and scuffs well. The backside of the material is smooth and glossy, but since it does not come with masking, this surface is prone to scratches and markings. We might be able to special order ABS that with smooth surfaces on both sides on request.

- We can UV print on both the smooth and haircell surfaces, but UV printing does not cover up the haircell texture. We expect most prints will look better on the smooth side and will print there by default unless you specify otherwise.

- ABS smells very bad when laser cut, so you might have to wash or air out the parts out upon receiving them to get rid of the smell.

|

|

Acetal/Delrin®

| Max thickness | 1/4″ (6.4 mm) |

|---|---|

| UV-printable | ✘ |

| Stocked | ✓ |

| RoHS 3 | ✓ |

| Stocked thicknesses | 3/64″ (1.2 mm) 1/16″ (1.6 mm) 1/8″ (3.2 mm) 3/16″ (4.8 mm) 1/4″ (6.4 mm) |

| Stocked layout sizes | 12″×12″ (30×30 cm) 12″×24″ (30×61 cm) 24″×24″ (61×61 cm) 24″×48″ (61×122 cm) |

| Stocked colors | black and white |

| Masking | added on request |

| Surface texture | smooth |

| Surface finish | glossy |

| Opacity | opaque (black) translucent (white) |

Notes:

- Acetal, is also know as Polyoxymethylene (POM) or by the brand name Delrin®.

- Acetal is a very rigid, tough, and slippery material that resists new warping and deformation well, but we often receive and cut parts from large sheets with slight warping which can be difficult to flatten.

- It has smooth, glossy surfaces that often have scratches since it does not come with masking.

- The slick surfaces are difficult to adhere to without sanding.

- Acetal and is commonly used to make gears.

- Acetal is the most expensive plastic that we stock.

|

Acrylic

| Max thickness | 1″ (25.4 mm) |

|---|---|

| UV-printable | ✓ |

| Primer recommended for UV printing |

✓ |

| Stocked | ✓ |

| RoHS 3 | Clear sheets only (see notes) |

| Stocked thicknesses | 0.75 mm (0.03″) 1.5 mm (0.06″) 3.0 mm (0.12″) 4.5 mm (0.18″) 5.6 mm (0.22″) 6.0 mm (0.24″) 9.0 mm (0.35″) 12.0 mm (0.47″) |

| Stocked layout sizes | 12″×12″ (30×30 cm) 12″×24″ (30×61 cm) 24″×24″ (61×61 cm) 24″×48″ (61×122 cm) see notes for more info |

| Stocked colors | see the More informationsection |

| Masking | film or paper |

| Surface texture | smooth |

| Surface finish | glossy matte mirror faux brushed metal |

| Opacity | transparent opaque translucent mirror |

Notes:

- Acrylic, also known as Plexiglas®, Lucite, and PMMA (polymethyl methacrylate), is our favorite material to work with.

- RoHS compliance documentation for colored acrylic sheets are generally unavailable due to constantly changing pigment materials.

- For more in-depth information on acrylic, please see the

More information about acrylic

section. - We usually stock larger sheets of common colors (black, white, and clear). Large sheets of other acrylic colors can sometimes be special ordered, but may have expensive freight costs.

- Two-tone acrylics are typically only available up to 24″×48″ (61×122 cm).

|

HDPE (high density polyethylene)

| Max thickness | 1/16″ (1.6 mm) |

|---|---|

| UV-printable | ✘ |

| Stocked | ✘ |

Notes:

- HDPE edges melt badly and produce a lot of dust that sticks to the parts when cut.

Kapton

| Max thickness | 0.050″ (1.3 mm) |

|---|---|

| UV-printable | ✘ |

| Stocked | ✘ |

Notes:

- Kapton is also known as polyimide film.

- Kapton chars badly when cut. Cutting adhesive-backed sheets increases the charring, and also causes the parts to be sticky.

Mylar

| Max thickness | 0.010″ (0.25 mm) |

|---|---|

| UV-printable | ✘ |

| Stocked | ✓ |

| RoHS 3 | ✓ |

| Stocked thicknesses | 0.003″ (0.08 mm) 0.004″ (0.10 mm) 0.005″ (0.13 mm) 0.010″ (0.25 mm) |

| Stocked layout sizes | see notes |

| Stocked colors | clear |

| Surface texture | smooth |

| Surface finish | glossy |

| Opacity | transparent |

Notes:

- Mylar is also known as polyester film.

- This is the same material used as transparency sheets with overhead projectors.

- We cut stocked Mylar from 40″ (102 cm) wide rolls, so the largest layout we can cut from stocked material 39.5″ × 47.5″ (100 × 121 cm).

- Also available with adhesive backing through suppliers like McMaster-Carr.

Nylon

| Max thickness | 1/16″ (1.6 mm) |

|---|---|

| UV-printable | untested |

| Primer recommended for UV printing |

untested |

| Stocked | ✘ |

Notes:

- Nylon edges melt, smell, and discolor badly when cut.

PETG (polyethylene terephthalate glycol)

| Max thickness | 1/8″ (3.2 mm) |

|---|---|

| UV-printable | ✓ |

| Primer recommended for UV printing |

✓ |

| Stocked | ✓ |

| RoHS 3 | ✓ |

| Stocked thicknesses | 1.5 mm (0.06″) 3.0 mm (0.12″) |

| Stocked layout sizes | 24″×48″ (61×122 cm) |

| Stocked colors | clear |

| Masking | film |

| Surface texture | smooth |

| Surface finish | glossy |

| Opacity | transparent |

Notes:

- PETG has good elasticity, so it can bend a lot before cracking or breaking.

- PETG smells very bad when cut, so you might have to wash or air out the parts out upon receiving them to get rid of the smell.

- The edges tend to melt and turn yellow from laser cutting even though sheets come with a film masking on both sides.

PE (polyethylene)

| Max thickness | 1/8″ (3.2 mm) |

|---|---|

| UV-printable | ✘ |

| Stocked | ✘ |

Notes:

- PE melts badly when cut.

PP (polypropylene)

| Max thickness | 1/8″ (3.2 mm) |

|---|---|

| UV-printable | ✘ |

| Stocked | ✘ |

Notes:

- PP melts somewhat when cut.

Styrene

| Max thickness | 1/8″ (3.2 mm) |

|---|---|

| UV-printable | ✓ |

| Primer recommended for UV printing |

✓ |

| Stocked | ✓ |

| RoHS 3 | ✘ |

| Stocked thicknesses | 0.030″ (0.76 mm) 1.5 mm (0.06″) 3.0 mm (0.12″) |

| Stocked layout sizes | 12″×12″ (30×30 cm) 12″×24″ (30×61 cm) 24″×24″ (61×61 cm) 24″×48″ (61×122 cm) |

| Stocked colors | white |

| Masking | added on request |

| Surface texture | smooth |

| Surface finish | matte |

| Opacity | opaque |

Notes:

- Styrene and has good elasticity, so it can bend a lot before cracking or breaking.

- It is easily machined with hand tools.

- Styrene smells very bad when cut, so you might have to wash or air out the parts out upon receiving them to get rid of the smell.

- Its edges melt somewhat when cut.

- Styrene is not as glossy as acrylic.

Teflon

| Max thickness | 1/8″ (3.2 mm) |

|---|---|

| UV-printable | ✘ |

| Stocked | ✘ |

Notes:

- Teflon melts somewhat when cut.

Metals

General notes about metals:

- We can typically cut metal alloys other than just the ones we stock.

- Other than UV printing, we do not offer any post-cutting services such as deburring, tumbling, polishing, bending, welding, anodizing, or coating. We ship parts as cut.

- Blemishes and light scratches may affect the surfaces of metal parts.

- Laser cutting metals may cause slight discoloration, dross formation, and burring. Typically, burring is minimal for metals under 1/8″ thick, but is more severe for thicker pieces.

Aluminum

| Max thickness | 1/4″ (6.4 mm) |

|---|---|

| UV-printable | ✓ |

| Primer recommended for UV printing |

✓ |

| Stocked | ✓ |

| Stocked alloys/types | 5052, 6061 |

| RoHS 3 | ✓ |

| Stocked thicknesses | 0.032″ (0.81 mm) 0.040″ (1.0 mm) 0.050″ (1.3 mm) 0.063″ (1.6 mm) 1/8″ (3.2 mm) |

| Stocked layout sizes | 12″×12″ (30×30 cm) 12″×24″ (30×61 cm) 24″×24″ (61×61 cm) 24″×48″ (61×122 cm) |

| Stocked colors | natural |

| Masking | not available |

| Surface texture | smooth |

| Surface finish | unpolished/mill |

| Opacity | opaque |

| Magnetic | ✘ |

Notes:

- The 5052 Aluminum we stock is easily weldable and bendable.

- See our general notes about metals.

|

Brass

| Max thickness | 1/8″ (3.2 mm) |

|---|---|

| UV-printable | ✓ |

| Primer recommended for UV printing |

✓ |

| Stocked | ✘ |

| Masking | not available |

| Magnetic | ✘ |

Bronze

| Max thickness | 1/8″ (3.2 mm) |

|---|---|

| UV-printable | ✓ |

| Primer recommended for UV printing |

✓ |

| Stocked | ✘ |

| Masking | not available |

| Magnetic | ✘ |

Notes:

- See our general notes about metals.

Mild steel

| Max thickness | 1/4″ (6.4 mm) |

|---|---|

| UV-printable | ✓ |

| Primer recommended for UV printing |

✓ |

| Stocked | ✓ |

| Stocked alloys/types | 1018 |

| RoHS 3 | ✓ |

| Stocked thicknesses | 0.030″ (0.76 mm) 0.060″ (1.5 mm) |

| Stocked layout sizes | 12″×12″ (30×30 cm) 12″×24″ (30×61 cm) 24″×24″ (61×61 cm) 24″×48″ (61×122 cm) |

| Stocked colors | natural |

| Masking | not available |

| Surface texture | smooth |

| Surface finish | unpolished/mill |

| Opacity | opaque |

| Magnetic | ✓ |

Notes:

- The 1018 steel we stock is also commonly called mild steel, low-carbon steel, or cold-rolled steel.

- 1018 steel is easily weldable, formable, and machinable.

- Some rust might affect the surface of mild steel parts, and they are vulnerable to further rust or corrosion.

- See our general notes about metals.

|

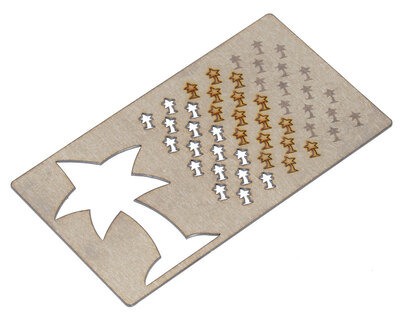

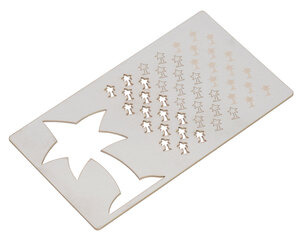

Through-cutting, vector etching, and raster engraving on mild steel. |

|---|

Spring steel

| Max thickness | 1/4″ (6.4 mm) |

|---|---|

| UV-printable | ✓ |

| Primer recommended for UV printing |

✓ |

| Stocked | ✘ |

| Masking | not available |

| Magnetic | depends on alloy/type |

Notes:

- See our general notes about metals.

|

Through-cutting, vector etching, and raster engraving on spring steel. |

|---|

Stainless steel

| Max thickness | 1/4″ (6.4 mm) |

|---|---|

| UV-printable | ✓ |

| Primer recommended for UV printing |

✓ |

| Stocked | ✓ |

| Stocked alloys/types | 304 |

| RoHS 3 | ✓ |

| Stocked thicknesses | 0.024″ (0.61 mm) 0.030″ (0.76 mm) 0.036″ (0.91 mm) 0.048″ (1.2 mm) 0.060″ (1.5 mm) |

| Stocked layout sizes | 12″×12″ (30×30 cm) 12″×24″ (30×61 cm) 24″×24″ (61×61 cm) 24″×48″ (61×122 cm) |

| Stocked colors | natural |

| Masking | not available |

| Surface texture | smooth |

| Surface finish | #2B unpolished/mill #3 brushed #4 brushed |

| Opacity | opaque |

| Magnetic | ✘ (see notes) |

Notes:

- The 304 stainless steel we stock is strong and weldable.

- Stainless steel parts are resistant to corrosion and rust.

- 304 stainless steel is not magnetic, but there are other types of stainless steel that are.

- See our general notes about metals.

|

|

Through-cutting, vector etching, and raster engraving on stainless steel. |

|---|

Woods

General notes about woods:

- We strongly recommend adding masking to minimize burn markings and discoloration from laser cutting.

- Primer is usually unnecessary for UV printing on wood since it is porous, though you can still add it to maximize adhesion strength.

Birch plywood

| Max thickness | 1″ (25.4 mm) |

|---|---|

| UV printable | ✓ |

| Primer recommended for UV printing |

✘ |

| Stocked | ✓ |

| RoHS 3 | ✓ |

| Stocked thicknesses | 1/16″ (1.6 mm) 1/8″ (3.2 mm) 1/4″ (6.4 mm) 3/8″ (9.5 mm) 1/2″ (12.7 mm) |

| Stocked layout sizes | 30″×24″ (76×61 cm) 30″×48″ (76×122 cm) |

| Stocked colors | natural |

| Masking | added on request |

| Surface texture/finish | natural |

| Opacity | opaque |

Notes:

- Birch plywood is a popular, eco-friendly plywood that is great for laser cutting.

- Stocked 1/8″ and thicker sheets are BB/BB grade.

- Small patches, light mineral streaks, and tight pin knots might affect both surfaces of the wood.

- The thickness of stocked sheets varies significantly.

- See our general notes about woods.

|

MDF (medium-density fiberboard)

| Max thickness | 1″ (25.4 mm) |

|---|---|

| UV printable | ✓ |

| Primer recommended for UV printing |

✘ |

| Stocked | ✓ |

| RoHS 3 | ✓ |

| Stocked thicknesses | 1/8″ (3.2 mm) 1/4″ (6.4 mm) 1/2″ (12.7 mm) |

| Stocked layout sizes | 24″×48″ (61×122 cm) |

| Stocked colors | natural |

| Masking | not available |

| Surface texture | smooth |

| Surface finish | natural |

| Opacity | opaque |

Notes:

- See our general notes about woods.

Other materials

Cardboard

| Max thickness | 5/32″ (3.97 mm) |

|---|---|

| UV printable | ✓ |

| Primer recommended for UV printing |

✘ |

| Stocked | ✓ |

| RoHS 3 | ✓ |

| Stocked thicknesses | 5/32″ (3.97 mm) |

| Stocked layout sizes | 40″x48″ (16×19 cm) |

| Stocked colors | natural (brown) |

| Masking | added on request |

Notes:

- Cardboard has a slight smell when laser cut.

- Primer is usually unnecessary for UV printing on cardboard since it is porous, though you can still add it to maximize adhesion strength.

- Corrugated cardboard sheets have a fluted center layer that makes bending/folding parts easier when the fold line is parallel to the flute direction. If that is important for your parts, please specify the flute direction in your file.

- For the cardboard we stock, the flutes are parallel with the 40″ edges.

Cardstock/paper

| Max thickness | |

|---|---|

| UV printable | ✓ |

| Primer recommended for UV printing |

✘ |

| Stocked | ✘ |

Notes:

- We can laser cut cardstock and paper, but it is usually more cost-effective to plot/die cut it instead.

- Laser cutting cardstock/paper might leave light burn marks. Darker colors are better at hiding burn marks.

Fabrics

| Max thickness | |

|---|---|

| UV printable | ✘ |

| Stocked | ✘ |

Notes:

- We have successfully laser cut various types of fabrics including acrylic, canvas, cordura, cotton, nylon, polyester, and wool.

- Edges of laser cut fabrics become cauterized (which helps prevent the fabric from fraying), but might have slight discoloration depending on the color.

- Fabric can be sent on a roll to avoid wrinkling.

Leather

| Max thickness | 1/8″ (3.2 mm) |

|---|---|

| UV printable | ✘ |

| Stocked | ✘ |

Notes:

- Synthetic leathers must be vinyl-free.

- All leather (both natural and synthetic) smells very bad when laser cut, so you might have to air the parts out once you receive them.

- Edges of laser cut leather will have noticeable char/soot on them. We ship parts as cut without dusting or cleaning them.