Pololu Blog »

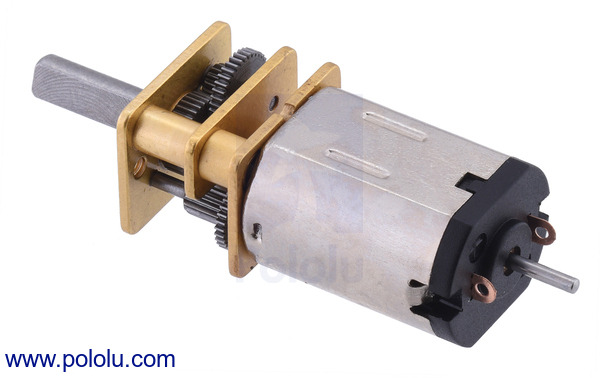

HPCB micro metal gearmotors with extended motor shafts

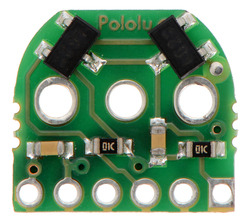

It has been a few months since we introduced our new high-power micro metal gearmotors with longer life carbon brushes. We now have them available with dual shafts, and we have made a corresponding update to our magnetic encoders to let them work with the larger terminals of the HPCB motors.

|

|

|

You might see similar-looking motors elsewhere, but no one comes close to our offering, from the quality of the gears to the variety of winding options to the selection of gear ratios, all in stock for shipment the day you order. By bringing together Pololu’s exclusive features of high-power windings, long-life carbon brushes, and encoders for closed-loop feedback control into a single package, these latest motors and encoders really demonstrate our continual investment in this popular form factor. With ten gear ratios available, from 10:1 through 1000:1, our total selection of micro metal gearmotors has grown to nearly 70 options:

| Motor Type | Stall Current @ 6 V |

No-Load Speed @ 6 V |

Approximate Stall Torque @ 6 V |

Single-Shaft (Gearbox Only) |

Dual-Shaft (Gearbox & Motor) |

|---|---|---|---|---|---|

| high-power, carbon brushes (HPCB) |

1600 mA | 3000 RPM | 4 oz-in | 10:1 HPCB | 10:1 HPCB dual-shaft |

| 1000 RPM | 9 oz-in | 30:1 HPCB | 30:1 HPCB dual-shaft | ||

| 625 RPM | 15 oz-in | 50:1 HPCB | 50:1 HPCB dual-shaft | ||

| 400 RPM | 22 oz-in | 75:1 HPCB | 75:1 HPCB dual-shaft | ||

| 320 RPM | 30 oz-in | 100:1 HPCB | 100:1 HPCB dual-shaft | ||

| 200 RPM | 40 oz-in | 150:1 HPCB | 150:1 HPCB dual-shaft | ||

| 140 RPM | 50 oz-in | 210:1 HPCB | 210:1 HPCB dual-shaft | ||

| 120 RPM | 60 oz-in | 250:1 HPCB | 250:1 HPCB dual-shaft | ||

| 100 RPM | 70 oz-in | 298:1 HPCB | 298:1 HPCB dual-shaft | ||

| 32 RPM | 125 oz-in | 1000:1 HPCB | 1000:1 HPCB dual-shaft | ||

| high-power (HP) (same specs as HPCB above) |

1600 mA | 6000 RPM | 2 oz-in | 5:1 HP | |

| 3000 RPM | 4 oz-in | 10:1 HP | 10:1 HP dual-shaft | ||

| 1000 RPM | 9 oz-in | 30:1 HP | 30:1 HP dual-shaft | ||

| 625 RPM | 15 oz-in | 50:1 HP | 50:1 HP dual-shaft | ||

| 400 RPM | 22 oz-in | 75:1 HP | 75:1 HP dual-shaft | ||

| 320 RPM | 30 oz-in | 100:1 HP | 100:1 HP dual-shaft | ||

| 200 RPM | 40 oz-in | 150:1 HP | 150:1 HP dual-shaft | ||

| 140 RPM | 50 oz-in | 210:1 HP | |||

| 120 RPM | 60 oz-in | 250:1 HP | |||

| 100 RPM | 70 oz-in | 298:1 HP | 298:1 HP dual-shaft | ||

| 32 RPM | 125 oz-in | 1000:1 HP | 1000:1 HP dual-shaft | ||

| medium-power (MP) |

700 mA | 2200 RPM | 3 oz-in | 10:1 MP | 10:1 MP dual-shaft |

| 730 RPM | 8 oz-in | 30:1 MP | |||

| 420 RPM | 13 oz-in | 50:1 MP | |||

| 290 RPM | 17 oz-in | 75:1 MP | 75:1 MP dual-shaft | ||

| 220 RPM | 19 oz-in | 100:1 MP | 100:1 MP dual-shaft | ||

| 150 RPM | 24 oz-in | 150:1 MP | |||

| 75 RPM | 46 oz-in | 298:1 MP | |||

| 25 RPM | 80 oz-in | 1000:1 MP | 1000:1 MP dual-shaft | ||

| low-power | 360 mA | 2500 RPM | 1 oz-in | 5:1 | |

| 1300 RPM | 2 oz-in | 10:1 | |||

| 440 RPM | 4 oz-in | 30:1 | 30:1 dual-shaft | ||

| 250 RPM | 7 oz-in | 50:1 | 50:1 dual-shaft | ||

| 170 RPM | 9 oz-in | 75:1 | |||

| 120 RPM | 12 oz-in | 100:1 | 100:1 dual-shaft | ||

| 85 RPM | 17 oz-in | 150:1 | |||

| 60 RPM | 27 oz-in | 210:1 | |||

| 50 RPM | 32 oz-in | 250:1 | |||

| 45 RPM | 40 oz-in | 298:1 | 298:1 dual-shaft | ||

| 14 RPM | 70 oz-in | 1000:1 | 1000:1 dual-shaft |

You can see all ten of the new versions below, and if there are any versions we do not yet have that you would like to see us carry, let us know in the comments!

3 comments

Thanks.

As we say in the blog post where we first introduced our micro metal gearmotors with long-life carbon brushes, there are operating conditions under which the carbon brushes allow the HPCB motors to last several times longer than HP versions with precious metal brushes (see that blog post for more information).

-Jon

Found that soldering the wires and motor tangs to the encoder PCB required a medium soldering skill level (I needed pointy soldering iron, and flux with mechanical hands).

When soldering, be careful of your pin (or wire) clearance for the through holes on the side of the PCB facing the motor housing (kinda tight).

I chose to solder the header (not included in 3081 encoder pair kit) I used onto the PCB first, then soldered the motor tangs. It looks like it would be a chore if soldered in the other order.

Before soldering the motor tangs to the PCB, I had to take care to align the through hole for the extended motor shaft as well. Magnetic encoder is light press fit onto the shaft (able to be done with fingers and seems on the shaft solid). After the first motor, soldering up the second motor was much easier.

Enjoy guys/gals!

-Billy