Pololu Blog »

The Manufacturing of A-Star 32U4 Micro

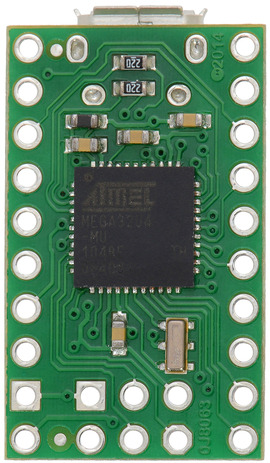

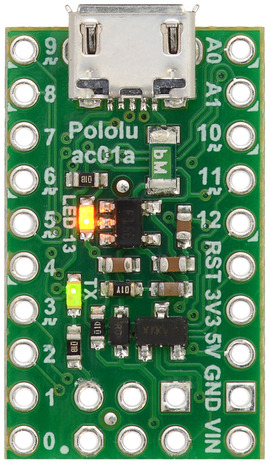

We recently released the A-Star 32U4 Micro, which we think is the best available AVR breakout board for its size. If you are like us, you enjoy taking factory tours, seeing how things are made on How It’s Made, and watching your Krispy Kreme doughnuts get created right before you personally eat them. Since most of you have not been able to visit us here in Las Vegas, we’ve made a video that shows how your A-Star Micro gets made!

The video shows how the A-Star Micro goes from a bare printed circuit board to an assembled and tested product. It is one of our more complex boards to make because it has components on both sides—this means two trips through the stencil printer, pick-and-place machine, reflow oven, and automated optical inspection machine. Here are some of the machines featured in the video:

- Speedprint SP700 AVI stencil printer

- Samsung SM421F pick and place

- Heller 1707 MK III reflow oven

- Nordson YESTECH BX-12 automated optical inspection

|

|

For those of you who like to be mesmerized by big machines moving thousands of tiny components quickly, we also have a video that shows the full pick-and-place sequence of a panel of forty A-Star Micros. (Note that this is not an accurate representation of the assembly time since the feeders are moved to the side to make room for the camera.)

For more videos like these, see our YouTube playlist: Pololu manufacturing: how our products are made and subscribe to our channel. By the way, you can still get a free A-Star Micro with your order over $100.