Support »

Pololu Zumo Shield for Arduino User’s Guide

View document on multiple pages.

You can also view this document as a printable PDF.

- 1. Overview

- 2. Assembly

- 3. The Zumo Shield in detail

- 4. Schematics and dimensions

- 5. Arduino pin assignment table

- 6. Zumo Shield Arduino library

- 7. Example sketches

- 8. Controlling a servo

1. Overview

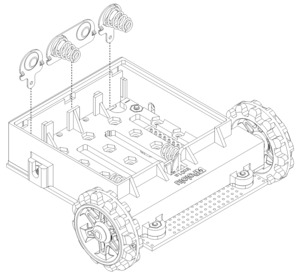

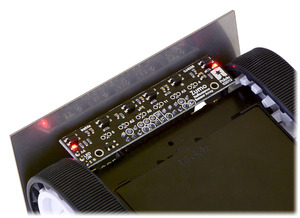

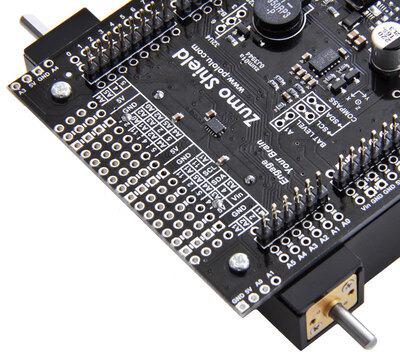

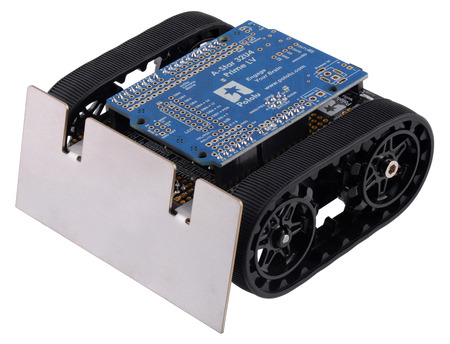

The Zumo Shield provides a convenient interface between our Zumo chassis and an A-Star 32U4 Prime, Arduino Uno, or Arduino Leonardo (it is not compatible with the Arduino Mega or Due, but it can be used with older Arduinos that have the same form factor as the Uno, such as the Duemilanove). The shield mounts directly to the chassis, connecting to its battery terminals and motors, and the Arduino plugs into the shield’s male header pins, face down. The shield provides all the electronics necessary to power the motors and includes some additional fun components for making a more interesting robot, such as a buzzer for making sounds and inertial sensors including an accelerometer and gyro.

|

|

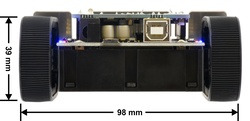

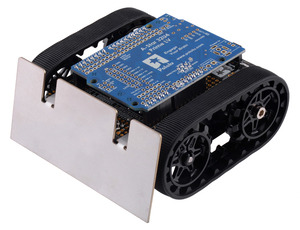

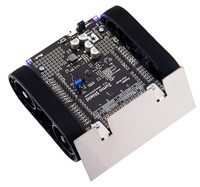

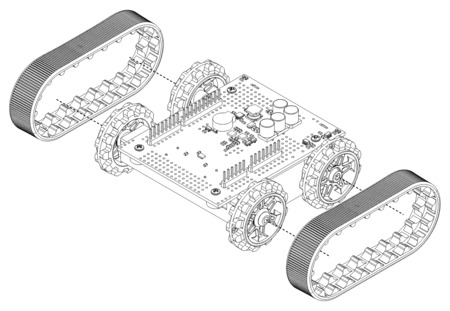

A Zumo chassis, Zumo Shield, and Arduino (or compatible board) can be combined to become a low-profile, Arduino-controlled tracked robot that is less than 10 cm on each side (small enough to qualify for Mini-Sumo competitions).

|

|

The Zumo Shield is available by itself, as part of a kit, or in a complete robot:

- Zumo Shield

- Zumo robot kit for Arduino with a Zumo chassis and a stainless steel Zumo blade

- Zumo robot for Arduino, fully assembled with 75:1 HP motors and a reflectance sensor array installed.

The latest revision of the Zumo Shield is version 1.3, which has an LSM6DS33 accelerometer and gyro, LIS3MDL magnetometer, and surface-mount power switch and pushbuttons. The information in this user’s guide also applies to the older Zumo Shield v1.2, which had an LSM303D accelerometer and magnetometer, L3GD20H gyro, and through-hole power switch and pushbuttons; and the original Zumo Shield, which had an LSM303DLHC accelerometer and magnetometer and no gyro. The original Zumo Shield, kit, and robot were sold with different product numbers:

As of July 10, 2015, the Zumo Robot for Arduino now features black, spoked sprockets. Older robots used white sprockets (which can still be seen in some of the pictures in this guide).

1.a. Contacting Pololu

|

Zumo Robot for Arduino. |

|---|

We would be delighted to hear from you about your experiences with the Zumo Shield for Arduino, Zumo robot kit for Arduino, or Zumo robot for Arduino. If you need technical support or have any feedback you would like to share, you can contact us directly or post on our forum. Tell us what we did well, what we could improve, what you would like to see in the future, or anything else you would like to say!

1.b. Included components

The Zumo Shield is available:

- by itself;

- as part of a Zumo robot kit for Arduino that also includes a Zumo chassis and a stainless steel Zumo blade; or

- as a fully-assembled Zumo robot for Arduino with 75:1 HP motors and a reflectance sensor array installed.

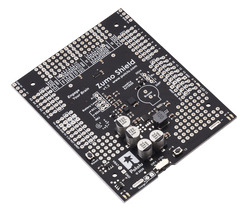

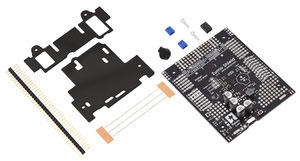

Zumo Shield

|

The shield itself comes with the following components:

- buzzer

- 2-pin battery-charging header

- right-angle slide switch (original and v1.2 only)

- two pushbuttons (original and v1.2 only)

- three jumper wires (for soldering motors to the shield)

- two 25-pin 0.1″ straight breakaway male headers

- four blue shorting blocks

- two 5/16″ #2-56 machine screws (to be used instead of the 1/4″ screws included with the chassis kit if you attach a Zumo blade)

- 1/16″ black acrylic spacer plate (two pieces)

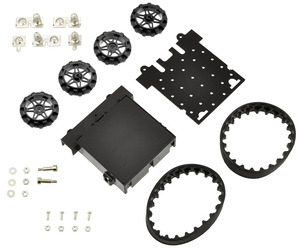

Zumo Robot Kit for Arduino

In addition to the shield and its included hardware, the Zumo robot kit for Arduino also includes these components:

|

- Zumo chassis kit, which includes:

- Zumo chassis main body

- 1/16″ black acrylic mounting plate (not used with the Zumo Shield)

- Two drive sprockets

- Two idler sprockets

- Two 22-tooth silicone tracks

- Two shoulder bolts with washers and M3 nuts

- Four 1/4″ #2-56 screws and nuts

- Battery terminals

|

You will receive the black acrylic spacer and mounting plates with protective paper masking on both sides. You can peel this masking off to expose the acrylic surface, or you can leave it on to increase the thickness of the plates.

The shield and chassis kit include extra parts like jumper wires, screws, nuts, and washers, so do not be concerned if you have some leftover hardware after assembling your Zumo.

Zumo Robot for Arduino

|

The Zumo robot for Arduino is a fully-assembled robot platform built from the same components found in the Zumo robot kit for Arduino, along with these additions:

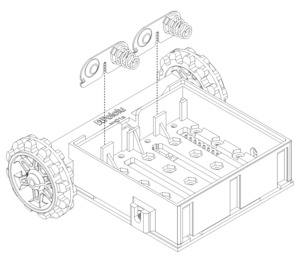

2. Assembly

If you have a Zumo robot kit for Arduino or a separate Zumo Shield and chassis, this section will guide you through assembling them into a complete robot.

If you purchased an assembled Zumo robot for Arduino, this assembly work has been done for you, although you might want to configure your Zumo by adding or removing some jumper connections. Otherwise, you can simply install four AA batteries and an Arduino (or compatible controller) and skip to Section 3 to start learning how to use your Zumo!

2.a. What you will need

The Zumo Shield is designed to be mounted on a Zumo chassis kit, which is included (along with a Zumo blade) if you have a Zumo robot kit for Arduino. In addition, you will require these items to construct a working Arduino-controlled Zumo robot:

Additional required components

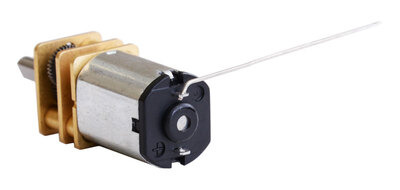

- Two micro metal gearmotors (we recommend 100:1, 75:1, or 50:1 gear ratio versions with HP or HPCB motors). The pre-assembled version of the Zumo robot includes two 75:1 HP micro metal gearmotors.

- An Arduino or compatible board (we recommend an A-Star 32U4 Prime, Arduino Uno R3, or Arduino Leonardo)

- Four AA batteries (we recommend rechargeable AA NiMH cells)

Please see the product description for the chassis kit for more information and recommendations about selecting these components.

Additional optional components

- Zumo reflectance sensor array

- Basic sumo blade for the Zumo chassis

- Sensors, such as our QTR reflectance sensors

- Connectors and jumper wires, for connecting additional sensors and components

- Battery charger (such as the iMAX-B6AC), if you are using rechargeable batteries

Assembly tools

- Soldering iron and solder (we recommend one with adjustable temperature control)

- Wire cutter

- Small Phillips screwdriver

- 3 mm Allen wrench (hex key)

- long-nose pliers (for bending the Zumo blade mounting tabs)

2.b. Assembling the Zumo Shield and chassis

Please follow these instructions carefully to assemble your Zumo Shield and chassis properly. (These pictures show the original Zumo Shield, but the assembly process also applies to newer ones including the latest v1.3 version.)

|

Through-hole parts

- Solder the included through-hole components to the shield:

- buzzer

- charging connector (1×2-pin female header)

- power switch (original and v1.2 only)

- reset pushbutton (original and v1.2 only)

- user pushbutton (original and v1.2 only)

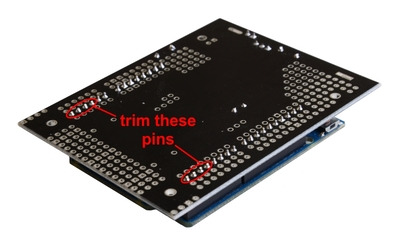

- On the bottom of the board, trim any leads longer than 1/16″ (the thickness of the spacer plate) so they do not prevent the shield from sitting flat on the spacer plate and chassis.

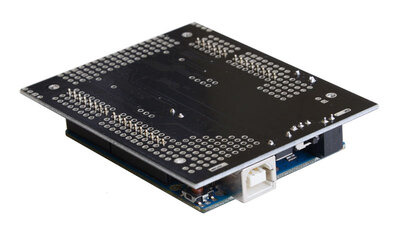

Arduino headers

- Separate the 1×40-pin breakaway male header into the appropriate segments for connecting your Arduino and solder them to the shield. These header segments should be soldered to the sets of holes outlined with white rectangles on the top of the shield, with the pins facing up.

The A-Star 32U4 Primes and the newest Arduino boards, including the Uno R3 and the Leonardo, use one 1×10 header, two 1×8 headers, and one 1×6 header; older Arduino boards use two 1×8 headers and two 1×6 headers (the two pairs of pins highlighted above in red should not be populated if you are using this board with an older Arduino that does not support these additional pins). Please make sure you solder the appropriate headers for your particular Arduino!

An easy way to line up the Arduino headers for soldering is to plug them into an Arduino, then place the shield upside-down on top of them, as shown in the picture below. Be careful to insert the header pins into the correct set of holes before you begin soldering. Note: if you use this alignment technique, make sure your soldering iron temperature is not excessively hot and avoid holding the iron on a single pin for more than a few seconds as this could melt the Arduino’s female headers.

|

- On the bottom of the board, trim the four Arduino header pins closest to the front of the board on each side to prevent them from contacting the motor housings. If you think there is a chance these pins might still touch the motor cases, you can put some electrical tape on the motors to act as insulation.

|

Jumpers and additional connections

- Optional: If you want to enable the buzzer, enable the battery level input, or disable the compass, now is a good time to add and/or cut jumper connections to configure the shield to your liking. This can also be done later, though soldering to these pins is more difficult once the robot is assembled (especially if you decide later you want to add header pins for use with shorting blocks; this would require a lot of disassembly). The jumpers are explained in detail in Section 3.c. The buzzer and battery level jumpers can be connected by soldering in a short piece of wire between the two holes, while the compass I²C connections can be broken by cutting the trace on the top of the board between the holes. Note: there is not enough clearance to use male headers on the battery level and compass I²C jumpers if you are using an Arduino with a DIP (through-hole) microcontroller.

Instead of making a wire connection, you can solder a 1×3 male header to the buzzer jumper holes to allow the use of a shorting block for connecting the buzzer. You can also use male headers and shorting blocks for the battery level jumper and compass jumpers if you have an Arduino Uno with an SMD (surface mount) microcontroller, Arduino Leonardo, or A-Star 32U4 Prime. However, there is not enough clearance to use male headers on the battery level and compass I²C jumpers if you are using an Arduino with a DIP (through-hole) microcontroller.

|

- Optional: At this point, you might consider soldering additional components (such as sensors), or headers or wires for connecting them, to the shield. If you do this, please check to make sure your part placement does not interfere with the shield’s ability to mate with the Arduino or the chassis. In particular, note that only components in the outermost three rows of the front expansion area can extend below the board (the fourth front-expansion row can only be used for pins extending above the board), and if you add any through-hole parts to the prototyping areas on the shield, you will need to drill corresponding holes in the acrylic spacer plate for the leads to fit into.

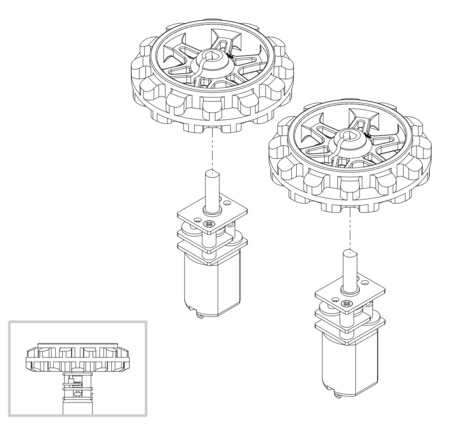

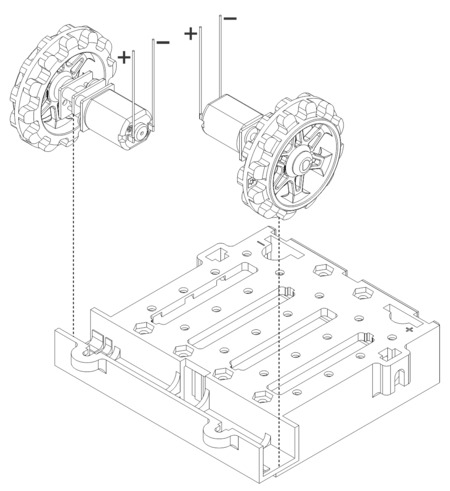

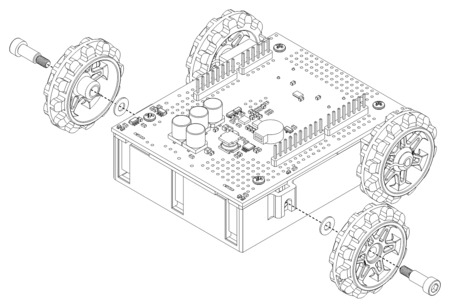

Motors and drive sprockets

- Press the output shafts of the motors into the drive sprockets, with the raised lip on one side of the sprocket facing away from the motor (as shown below). The end of the gearbox shaft should end up flush with the outside of the sprocket. A good way to do this is to set the wheel on flat surface (like a table top) and press the motor shaft into the wheel until it contacts the surface.

|

- Cut two of the included jumper wires in half to form four segments, and trim off the ends that are covered in adhesive (the adhesive could interfere with making a good electrical connection to the motor). These wire segments will be used as motor leads.

- Solder a pair of leads to each motor in the orientation described below. You might find it helpful to make a small bend at the tip of each lead to hook into the hole in the motor lead tab to hold it in place for soldering. Warning: holding the soldering iron against the motor lead for more than a few seconds can start to damage the motor brushes, so try to be reasonably quick/efficient with this soldering; if the first attempt does not go well, remove the soldering iron and let the motor cool for a few seconds before trying again.

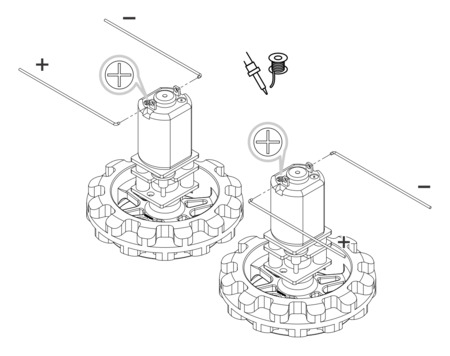

|

Each motor’s positive terminal is indicated by a plus sign (+) in the black plastic end of the motor, as indicated in the picture below. The motors should be soldered into the shield with the positive terminal closest to the front, so you should attach the leads to allow the motors to be oriented this way. (However, don’t worry if you accidentally get the orientation of one or both motors wrong. You can later compensate for it in software with our Zumo Shield Arduino library.)

|

- Place the motors into the channel in the front of the chassis, aligning the gearbox with the grooves in the channel. The front plate of the gearbox should be even with the edge of the chassis.

|

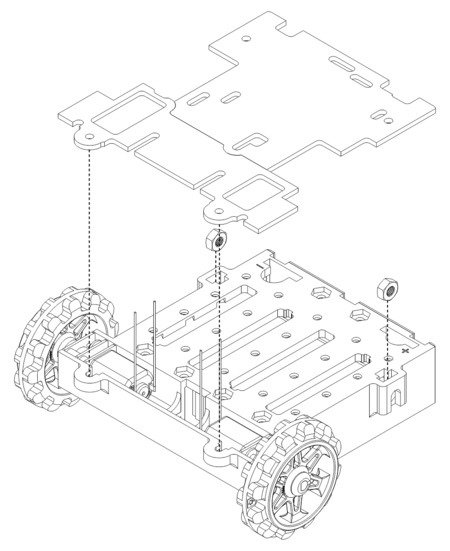

Chassis and shield

To assemble the chassis with the Zumo Shield, you should use the two-piece acrylic spacer plate that is included with the shield. You will not need the one-piece mounting plate that is included with the Zumo chassis.

- Place an M3 nut in each of the two side slots near the rear of the chassis. The slots are sized so that nuts will not be able to rotate within them. (These nuts will be used to mount the idler sprockets later.)

- If you want, peel the protective paper masking off both sides of the acrylic spacer plate pieces. Alternatively, you can leave the masking on for additional thickness. If you leave the masking on, it will be mostly concealed when the robot is fully assembled.

- Cover the chassis and motors with the spacer plate pieces and then the Zumo shield. The holes in the spacer plate should line up with the through-holes in the shield resting on top of it, and the motor leads should be aligned so they pass through the slots in the spacer as shown in the picture below. There is only one correct orientation for these plates. (The plate consists of two separate pieces to make it possible to disassemble the Zumo without having to desolder the motors or battery terminals.)

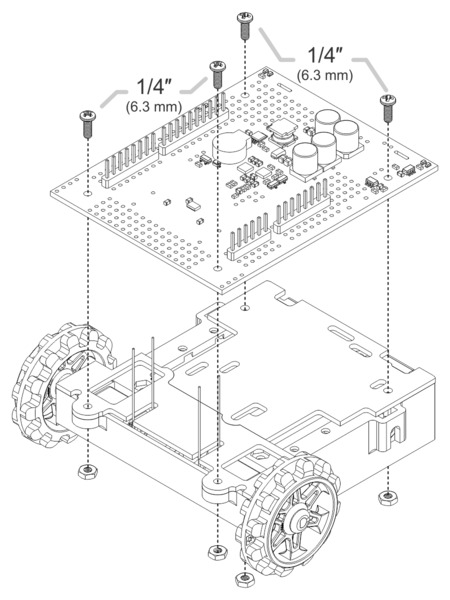

|

- In each of the four mounting holes, insert a #2-56 machine screw through the shield, spacer plate, and chassis, and tighten it against a nut under the chassis. It is usually easier to place the nut into the recess first and hold it there with a finger or piece of tape while inserting the screw. Note that the kit includes two different sizes of #2-56 machine screws: 1/4″and 5/16″. The two longer screws are intended for use in the front holes (near the motors) if you are also mounting a sumo blade; otherwise, you can use the shorter 1/4″ screws for all four mounting holes.

|

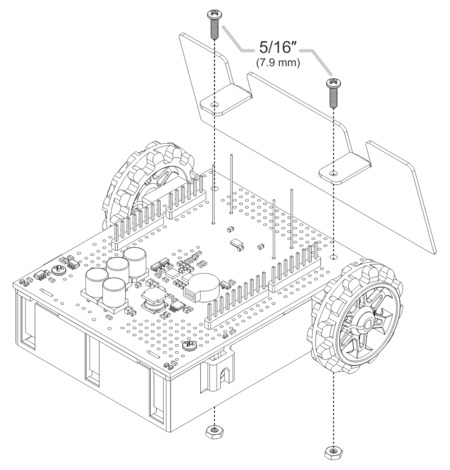

If you are also adding a basic sumo blade, you can either mount it now or add it later after you are done soldering the motors and battery contacts. (Note: If you intend to solder anything to the front expansion area of the shield, such as a Zumo reflectance sensor array, you will have more room to work if you do the soldering before adding the sumo blade.)

To install the blade, first bend its mounting tabs to the appropriate angle. Next, place them on top of the shield so that the holes line up with the two front mounting holes and insert the two longer (5/16″) #2-56 machine screws (included with the shield) through the blade, shield, spacer plate, and chassis. Be careful when adjusting the angle of the sumo blade while it is mounted to the chassis, as this can crack the acrylic spacer plate if you apply sudden or excessive force. We recommend you do not try bending the blade while it is mounted to the chassis.

|

- Solder each motor lead to the shield, then trim off the excess length of wire.

|

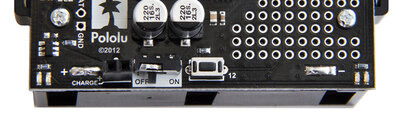

Battery contacts

- Turn the chassis over and install the battery terminal contacts as shown in the picture below. The three double-contact pieces should be firmly pressed into place until they are flush with the interior surface of the battery compartment. The two individual contacts should be inserted into the battery compartment so that their solder tabs protrude through the holes in the top of the chassis; you might want to temporarily tape these two individual contacts in place until they have been soldered to the shield as described in the next step, or you can use a battery to temporarily hold them in place.

|

|

- Solder the two individual contacts to the shield from the top. Note that if you are using a battery to hold the contact in place during soldering, the battery might act as a heat sink, making it more difficult to solder or requiring a higher soldering iron temperature. The battery terminal slot in the PCB should be completely filled with solder as shown in the picture below.

|

Idler Sprockets and track

- Place an idler sprocket on each shoulder bolt, followed by a washer. The protruding side of the sprocket hub should face the same direction as the threaded end of the bolt (in toward the chassis).

- Insert the shoulder bolts through the side of the chassis into the nut. Use a 3 mm hex key (Allen wrench) to tighten the bolts until the washers are snug against the chassis. Be careful not to overtighten the shoulder bolts as doing so can bend the washers. Note: Be careful if you use threadlocking adhesives like Loctite as these can corrode the chassis. You should first test any such adhesives on a concealed part of the chassis to ensure they will not damage it.

|

- At this point, you can add the silicone tracks by stretching them around the sprockets on each side of the chassis. Your Zumo Shield and chassis are now complete; just add batteries and an Arduino to get your Zumo robot moving!

|

|

Disassembly

If you later decide you want to solder additional parts to the Zumo Shield, it is possible to remove it from the chassis with some careful effort.

- Remove the tracks from the chassis.

- Remove the battery cover and batteries from the chassis.

- Unscrew all four sets of machine screws and nuts holding the shield to the chassis.

- Squeeze the negative battery terminal spring and gently ease both battery terminals out through the holes in the chassis. The motors will stay attached to the shield as it separates from the chassis.

- Carefully bend both motors away from the shield to allow the front piece of the spacer plate to be removed.

You can reassemble the Zumo afterwards by following this procedure in reverse. (Make sure to replace the spacer plate pieces properly.)

2.c. Adding a Zumo reflectance sensor array (optional)

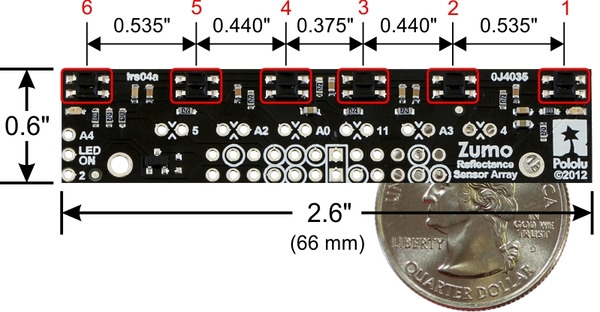

Overview

The Zumo reflectance sensor array is an easy way to add line-following and edge-detection capabilities to the Zumo robot. It is designed specifically to mount to the front expansion area of the Zumo shield, and it includes everything you need for installation. Note that the reflectance sensor array is not included with the Zumo shield or Zumo Robot Kit, and the Zumo robot can be used without it. For more information on the Zumo reflectance sensor’s capabilities and how it works (including a schematic diagram), please see its product page. This section is devoted specifically to assembling the sensor and using it with the Zumo shield.

|

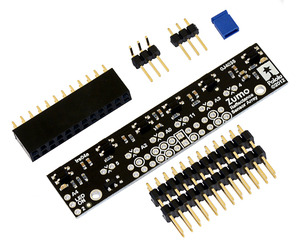

Assembling the sensor array

|

The Zumo reflectance sensor array ships with all of the components you need to connect it to a Zumo shield:

- sensor array PCB with the surface-mount parts pre-populated

- 2×12 extended 0.1″ male header (will be soldered to sensor PCB)

- 2×12 0.1″ female header (will be soldered to Zumo shield)

- 1×3 0.1″ straight male header (optionally soldered to sensor PCB)

- 1×3 0.1″ right-angle male header (optionally soldered to sensor PCB)

- blue shorting block

Before soldering in the main male header strip, we recommend soldering one of the two included 1×3 male headers into the set of three holes along the edge of the board. This step is optional but recommended because it allows dynamic control of the IR emitters (and red LEDs). By controlling when these LEDs are on, you can save power and make your programs easier to debug. If you skip this step, the IR emitters will just be on whenever the sensor array is plugged in and the Zumo is on. We recommend using the right-angle header mounted as shown in the picture below, but the straight 3-pin header will also work if you do not have anything already soldered to the Zumo shield’s front expansion area that would interfere. If you choose to install this header, please make sure you are doing it in a way that will not prevent installation of the sensor array (e.g. by installing it on the wrong side or by installing the right-angle pins in the wrong orientation)! If you are going to install this 3-pin header, it is generally easier to do so before soldering the larger 24-pin header.

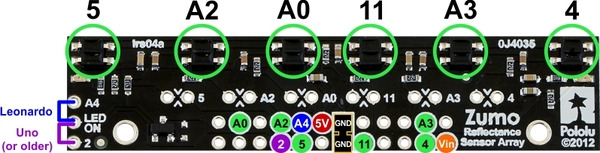

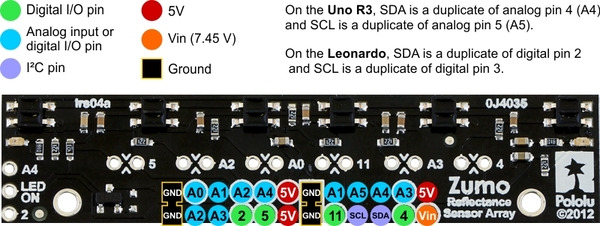

To enable dynamic control of the IR emitters, install the 3-pin header and use the included blue shorting block to connect the LEDON pin to the appropriate digital I/O pin. If you are using an Arduino Uno or older Arduino, you should use the shorting block to connect LEDON to digital pin 2 (the position that puts it flush with the edge of the board); if you are using an Arduino Leonardo or A-Star 32U4 Prime, you should use the shorting block to connect LEDON to analog pin 4 (A4).

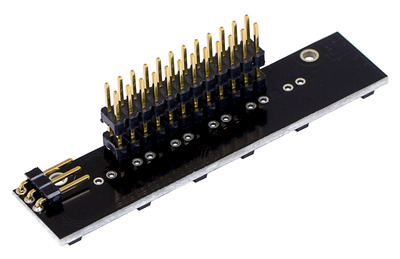

|

The extended 2×12 male header strip should be mounted to the sensor array PCB on the opposite side from the components. Make sure you solder the shorter side of the pins to the PCB, not the longer side! Note that only 12 of the 24 pins are actually used by the sensor array; these pins have silkscreen circles around them on the component side of the board, and these are the only pins that need to be soldered, though it is fine to solder all 24 pins.

Connecting to the Zumo shield

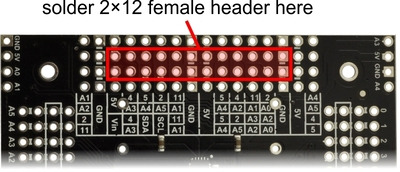

The 2×12 female header included with the reflectance sensor array should be soldered to the front expansion area of the Zumo shield so that it is centered in the expansion area and flush with the Zumo chassis (rows 2 and 3). While it is fine to solder all 24 pins to the shield, only the 12 pins required by the reflectance sensor array need to be soldered (see the Array pinout section below for more information on which pins are required).

|

|

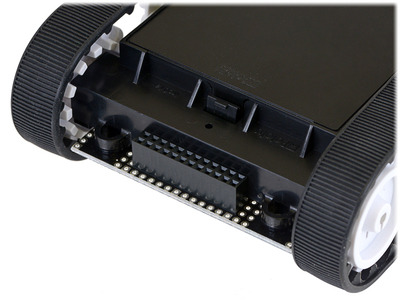

With the female header in place, the assembled sensor array can be plugged directly into the Zumo shield.

|

|

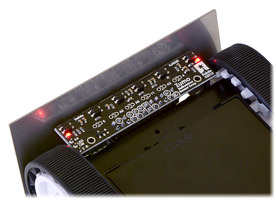

The reflectance sensor array features two visible (red) LEDs in series with the IR emitter LEDs, so you can use the red LEDs to tell when the emitters are on and off.

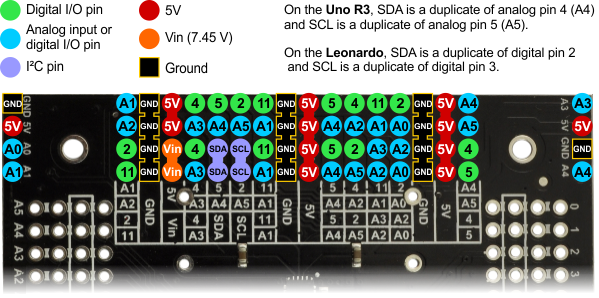

Array pinout

The Zumo reflectance sensor array gets all the necessary power and I/O connections from the 12 header pins that are circled on the silkscreen:

|

The default I/O connections are to pins that are otherwise unused by the Zumo shield. The shield uses one digital I/O pin for each sensor (5, A2, A0, 11, A3, and 4), and if you add the LEDON shorting block, one additional pin (either A4 or 2) is used. To configure the ZumoReflectanceSensorArray object to use this default pinout, simply call init with no arguments:

reflectanceSensors.init();

If you opt to leave off the LEDON shorting block, you should use the QTR_NO_EMITTER_PIN initialization parameter: reflectanceSensors.init(QTR_NO_EMITTER_PIN). Otherwise, the library code will still be trying to do something with the emitter pin (A4 or 2, depending on which Arduino you are using), and this would interfere with your being able to use that pin for alternate purposes.

When soldering the male 2×12 header to the sensor array, you only need to solder those pins that you will be using. If you solder all 24 pins, the sensor array will be connected to additional pins from the Zumo shield’s front expansion area, though the array does not do anything with them in its default configuration:

|

Disabling or remapping sensors

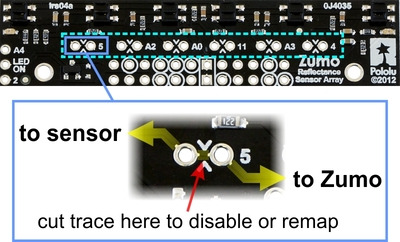

Many applications do not require all six reflectance sensors, and you might want additional I/O lines for other things (e.g. obstacle detectors). In such cases, you can disable specific sensors and free up their associated I/O lines. The array PCB has six pairs of through holes, each of which corresponds to a different sensor. The order of the pairs matches the order of the sensors. When viewing the component side of the PCB, the right hole of each pair connects to an Arduino I/O line and the left hole connects to sensor. There is a single trace on the component side of the PCB between the two holes of each pair, and this trace can be cut to disable the sensor and free up the I/O line. The proper place to cut is marked on the silkscreen by carets.

|

For example, if you want to use your Zumo for solving a line maze, you can likely get by with just four sensors: you can use the middle two sensors for tracking the line and the outer two sensors for detecting intersections. To free up the I/O lines associated with the other two sensors, you could make the following modification:

|

Now you effectively have a four-sensor array and analog pins A2 and A3 are available for general-purpose use. To configure the ZumoReflectanceSensorArray object to use this new configuration, call init with these arguments:

byte pins[] = {4, 11, A0, 5};

reflectanceSensors.init(pins, 4);

Alternatively, you could make two ZumoReflectanceSensorArray objects, one for the two exterior sensors and another for the two interior sensors, which might allow for cleaner code, but the drawback is that you can no longer read all four sensors in parallel with this approach.

If you later decide you want to re-enable those sensors, you can connect across the cut trace with a wire, or you can use a wire to remap the sensor to a different pin. The following example shows how you could re-enable the A2 sensor and remap the A3 sensor to pin A5 instead:

|

To configure the ZumoReflectanceSensorArray object to use this remapped configuration, call init with these arguments:

byte pins[] = {4, A5, 11, A0, A2, 5};

reflectanceSensors.init(pins, 6);

Or, if you are not using an I/O line to control the IR emitters:

byte pins[] = {4, A5, 11, A0, A2, 5};

reflectanceSensors.init(pins, 6, 2000, QTR_NO_EMITTER_PIN); // 2000 = timeout after 2 ms

3. The Zumo Shield in detail

3.a. Features and components

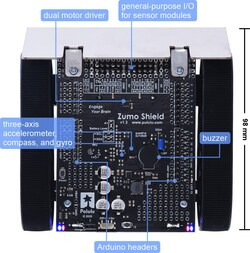

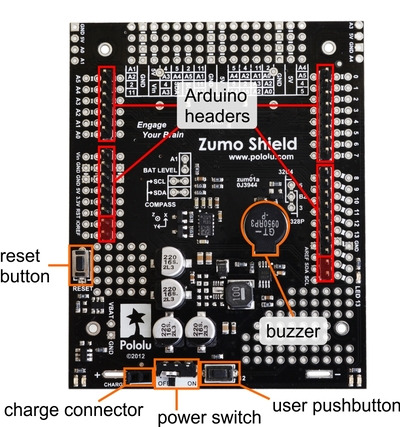

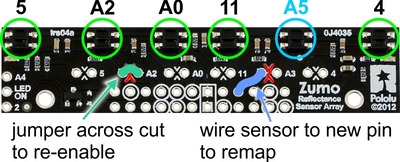

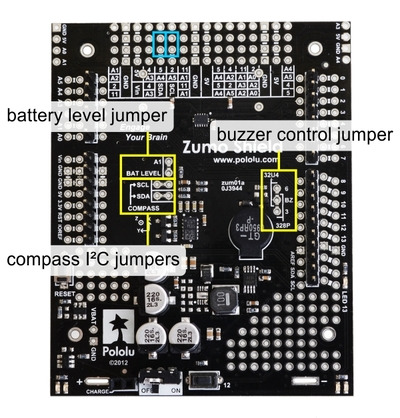

The main features of the Zumo Shield (v1.3) are labeled in this diagram:

|

Power

The Zumo chassis has an internal compartment for four AA batteries. We recommend using rechargeable AA NiMH cells, which results in a nominal voltage of 4.8 V (1.2 V per cell). You can also use alkaline cells, which would nominally give you 6V.

A direct connection to the battery terminals is provided by the battery charger connector on the rear edge of the shield, which can be used to recharge the Zumo’s batteries without removing them from the chassis. The positive pin of the charge connector, on the left, is indicated by a plus sign (+). A charger like the iMAX-B6AC, connected by clipping its alligator clips to a pair of jumper wires inserted into the charge connector, works well for charging the Zumo.

After passing through reverse protection, the battery voltage is connected to the rest of the shield by the power switch. The switched battery voltage is designated VBAT and provides power to the motors through the DRV8835 motor driver. An on-board boost regulator, also supplied from VBAT, generates 7.45 V to power the Arduino through its Vin pin. In turn, the Arduino’s regulated 5V and 3.3V voltages supply power to the motor driver logic, buzzer circuit, and compass module on the Zumo Shield.

Warning: When powering the Arduino from the Zumo Shield, you must never connect a different power supply to the Arduino’s VIN pin or plug a power supply into the Arduino’s power jack, as doing so will create a short between the shield’s power supply and the Arduino’s power supply that could permanently damage both the Arduino and the Zumo Shield.

When the Arduino is connected to a computer via USB, it will receive power (and supply 5V and 3.3V to the shield) even when the Zumo Shield’s power switch is off. This can be useful if you want to test your Arduino program without allowing the motors to run, since turning the power switch off disconnects motor power (VBAT).

LEDs

There are five LEDs on the Zumo Shield:

- A set of power LEDs, one blue and one red, is located in each of the two rear corners of the shield.

- A yellow user LED is located on the right edge of the shield. It is connected to digital pin 13 on the Arduino, in parallel with the Arduino’s onboard user LED.

Pushbuttons

Two pushbuttons can be soldered to the Zumo Shield:

- The reset pushbutton is located on the left edge of the shield. It is connected to the Arduino’s RESET pin and can be pressed to reset the Arduino.

- The user pushbutton is located on the rear edge of the shield. It is connected to digital pin 12 on the Arduino; pressing the button pulls the pin low, and we recommend enabling the Arduino’s internal pull-up to pull the pin high otherwise. The Pushbutton part of our Zumo Shield Arduino library, makes it easy to detect and debounce button presses with this pushbutton.

Motor driver

An integrated DRV8835 dual motor driver on the Zumo Shield drives the Zumo’s two micro metal gearmotors. Four Arduino pins are used to control the driver:

- Digital pin 7 controls the right motor direction (LOW drives the motor forward, HIGH drives it in reverse).

- Digital pin 8 controls the left motor direction.

- Digital pin 9 controls the right motor speed with PWM (pulse width modulation).

- Digital pin 10 controls the left motor speed with PWM.

The ZumoMotors object in the Zumo Shield Arduino library provides functions that allow you to easily control the motors, and it can optionally take care of flipping a direction signal for you if you accidentally soldered in a motor backwards.

Buzzer

The Zumo Shield comes with a buzzer that can be used to generate simple sounds and music (for example, you could use it to produce an audible countdown at the beginning of a sumo match). The buzzer control line is labeled BZ on the shield; if you alternate between driving it high and low at a given frequency, the buzzer will produce sound at that frequency.

The ZumoBuzzer object in the Zumo Shield Arduino library uses hardware PWM to play notes on the buzzer, with digital pin 3 (OC2B) on an Arduino Uno or an older Arduino, or with digital pin 6 (OC4D) on an Arduino Leonardo or A-Star 32U4 Prime. A jumper is provided to connect the BZ input to the appropriate Arduino output, as detailed in Section 3.c.

Front expansion area

A number of I/O, power, and ground connections are brought to the front of the Zumo Shield to allow the mounting of additional sensors and other components. The pinout of this front expansion area is detailed in Section 3.b.

Inertial sensors

The Zumo Shield includes on-board inertial sensors, which can be used to sense acceleration and orientation for advanced applications:

- The v1.3 Zumo Shield features an LSM6DS33 3-axis accelerometer and gyroscope and an LIS3MDL 3-axis magnetometer.

- The v1.2 Zumo Shield features an LSM303D 3-axis accelerometer and magnetometer and an L3GD20H 3-axis gyroscope.

- The original Zumo Shield features an LSM303DLHC 3-axis accelerometer and magnetometer.

The inertial sensors are detailed in Section 3.d.

3.b. Front expansion

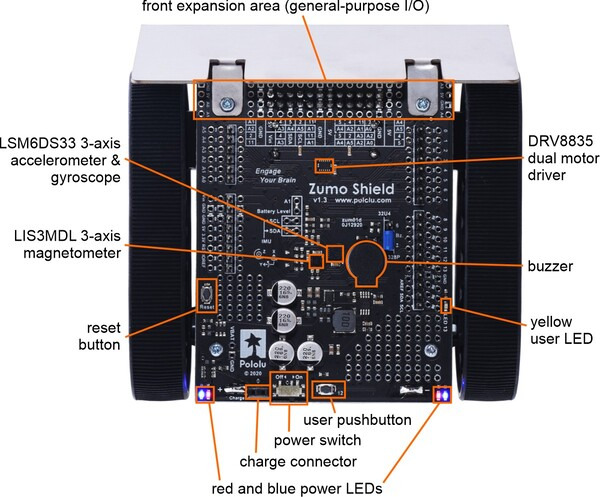

The pins in the front expansion area of the Zumo Shield are shown in the following diagram:

|

This diagram is also available as a downloadable PDF: Zumo Shield front expansion pinout (552k pdf).

The front expansion makes available digital pins 2, 4, 5, and 11 and analog pins A0 through A5. It also provides access to the two I²C pins (SDA and SCL). However, please note that the I²C pins are not independent pins; they are respectively duplicates of analog pins A4 and A5 on the Uno R3 and digital pins 2 and 3 on the Leonardo and A-Star 32U4 Prime. Typically, you will only be able to use these pins for either I²C communication or general I/O, not both. Additionally, pin A1 is used to monitor the battery voltage if you install the battery monitor jumper.

Please note that only components and connectors in the front three rows of pins can extend below the shield; the fourth row covers the chassis and is only suitable for components mounted above the shield.

If you use an Arduino Uno R2 or an older Arduino, which lack separate I²C pins, the SDA and SCL pins on the Zumo Shield will not be connected to anything. To use an I²C device on those pins, you can connect SDA to A4 and SCL to A5 yourself by bridging across those two sets of pins in the front expansion area. Section 3.c further explains the I²C lines and the jumpers connecting them to the on-board compass module.

Depending on the Arduino model, digital pin 3 or 6 is used to control the buzzer if you install the buzzer control jumper. If you are using an Uno, pin 6 will be available for general-purpose I/O. If you are using a Leonardo or A-Star, pin 3 will be available if you are not using I²C. These pins are not accessible via the front expansion, but they can be accessed from other points on the shield and used for interfacing with additional electronics if free. Additionally, digital pin 12 can be used for interfacing with many types of additional electronics, especially if you are not using the shield’s user pushbutton. Pin 12 is completely free when the pushbutton is in its default, unpressed state, and it is pulled low through a 1k resistor when the pushbutton is pressed.

3.c. Jumper settings

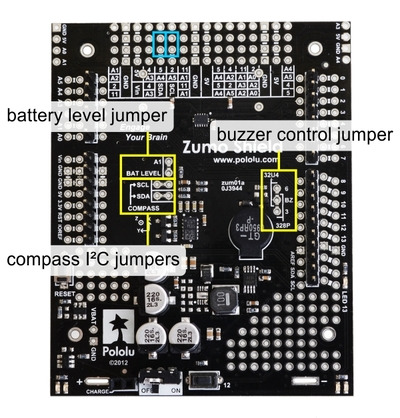

The Zumo shield has several jumpers that let you change the way it is connected to the Arduino, as shown in the picture below.

|

- The battery level jumper connects the Arduino’s analog pin 1 to a voltage divider circuit that allows you to monitor the Zumo’s battery voltage. This jumper is disconnected by default and can be connected by soldering a short length of wire between the two holes.

The divider outputs a voltage equal to two-thirds of the battery voltage, which will always be safely below the Arduino’s maximum analog input voltage of 5 V. For example, at a battery voltage of 4.8 V, analog pin 1 will be at a level of 3.2 V. Using Arduino’s analogRead() function, where 5 V is read as a value of 1023, 3.2 V is read as a value of 655. To convert it back to the actual battery voltage, multiply this number by 5000 mV×3/2 and divide by 1023:

unsigned int batteryVoltage = analogRead(1) * 5000L * 3/2 / 1023;

- The buzzer control jumper connects one of the Arduino’s PWM outputs to the buzzer on the Zumo Shield. This jumper is disconnected by default on both the assembled and kit versions of the Zumo robot; it must be connected to enable the buzzer.

If you have an Arduino Uno or an older Arduino (with an ATmega328P or ATmega168 microcontroller), you should jumper the two holes bracketed with the label 328P to connect the BZ pin to digital pin 3. If you have an A-Star 32U4 Prime or Arduino Leonardo, you should jumper the two holes bracketed with the label 32U4 to connect the BZ pin to digital pin 6. These are the pins our Zumo Shield Arduino library expects the buzzer to be connected to for each respective microcontroller. More details about the buzzer can be found in Section 3.a.

- The compass/gyro I²C jumpers connect the I²C clock (SCL) and data (SDA) lines of the inertial sensors on the Zumo Shield to the SCL and SDA pins on the Arduino. These jumpers are connected by default, but can be disconnected by cutting the thin trace between each pair of holes.

On the Arduino Uno R3, SCL and SDA are duplicates of analog pins 5 and 4, respectively. On the A-Star and Arduino Leonardo, SCL and SDA are duplicates of digital pins 3 and 2, respectively. Using the I²C sensors on the shield will prevent these pins from being used for other purposes, and the I²C pull-up resistors will affect readings on these pins even if the compass is not being actively used, so you must cut the jumpers to disconnect the inertial sensors and pull-ups if you want to repurpose the SCL and SDA pins.

Please note that the SCL and SDA pins do not exist on Arduino hardware versions prior to the Uno R3, so you will have to manually connect SCL to analog pin 5 and SDA to analog pin 4 on the Zumo Shield in order to use the compass with an older Arduino. The most convenient place to do this is in the front expansion area, where these pins are all located together, as indicated by the light blue boxes in the picture above.

More details about the inertial sensors can be found in Section 3.d.

Instead of making a wire connection, you can solder a 1×3 male header to the buzzer jumper holes to allow the use of a shorting block for connecting the buzzer (note: this header is already installed if you got the assembled version of the Zumo robot, but the shorting block must be positioned in the appropriate place for the Arduino model you are using). You can also use male headers and shorting blocks for the battery level jumper and compass jumpers if you have an Arduino Uno with an SMD (surface mount) microcontroller, Arduino Leonardo, or A-Star 32U4 Prime. However, there is not enough clearance to use male headers on the battery level and compass I²C jumpers if you are using an Arduino with a DIP (through-hole) microcontroller.

3.d. Inertial sensors (accelerometer, magnetometer, and gyro)

Overview

The Zumo Shield includes on-board sensors that can be used as an inertial measurement unit (IMU) for applications like helping your Zumo detect collisions and determine its own orientation.

All versions of the Zumo Shield have a 3-axis accelerometer and 3-axis magnetometer accessible via I²C. Newer v1.2 and v1.3 boards also have a 3-axis gyroscope on the same I²C bus. The specific inertial sensor chips used on a shield depend on its version:

- The v1.3 version uses an LSM6DS33 accelerometer and gyro and an LIS3MDL magnetometer.

- LSM6DS33 datasheet (1MB pdf)

- LIS3MDL datasheet (2MB pdf)

- The v1.2 version uses an LSM303D accelerometer and magnetometer and an L3GD20H gyro.

- LSM303D datasheet (1MB pdf)

- L3GD20H datasheet (3MB pdf)

- The original version uses an LSM303DLHC accelerometer and magnetometer (it does not have a gyro).

- LSM303DLHC datasheet (1MB pdf)

We recommend carefully reading the datasheets listed above to understand how these sensors work and how to use them.

Using the sensors

Level shifters built into the shield allow the inertial sensors, which operate at 3.3 V, to be connected to the 5 V logic level pins of the Arduino. The sensors, level shifters, and I²C pull-up resistors are connected to the SCL and SDA pins on the Zumo Shield by default, but they can be disconnected by cutting traces to allow those pins to be used for other purposes. It is necessary to make some additional connections on the shield if you want to use the compass with an older Arduino without separate SCL and SDA pins; please see Section 3.c for more details about the compass connections.

The ZumoIMU object in the Zumo Shield Arduino library provides functions that help configure and read the inertial sensors, and it abstracts details of the specific sensor ICs to make it easier to write programs that will work on all versions of the Zumo Shield. The library includes an example project that demonstrates how to use the magnetometer to help the Zumo coordinate its turns.

For advanced applications, you can instead use some of the dedicated libraries that we have written for these sensor chips; these include our LSM6 Arduino library, LIS3MDL Arduino library, LSM303 Arduino library, and L3G Arduino library. The v1.3 and v1.2 Zumo Shields use the same inertial sensor ICs as some of our IMU boards, like the MinIMU-9 v5, so Arduino software written for the MinIMU-9 (such as our AHRS example) can also be adapted to work on an Arduino-controlled Zumo robot with one of these shields.

Notes on the magnetometer

Please note that the magnetometer on the Zumo Shield is affected by currents in the motors and buzzer when they are operating, as well as metal in the batteries, and the readings are easily influenced by magnetic distortions in the environment around the Zumo (such as rebar in a concrete floor). As a result, it is very hard to accurately determine the Zumo’s absolute heading based on the magnetometer data. However, in our tests, we found that the magnetometer was still useful for detecting relative orientation changes; for example, once the magnetic readings are compensated for a particular environment, they can be used to help the Zumo turn left or right by a specific angle instead of just timing how long to run the motors to make such a turn.

In our tests, we found that the batteries, motors, and motor current affect the z axis of the magnetometer much more strongly than the x and y axes, so you probably will want to ignore the z readings. We were generally able to get decent results using only the x and y magnetometer readings to determine heading. Additionally, you might need to decrease the magnetometer sensitivity; if the magnetometer returns a value of -4096, that is a sign that the sensitivity range is set too narrow for your particular environment.

4. Schematics and dimensions

Schematics

Schematic diagrams of the Zumo Shield are available as a downloadable PDF:

- v1.3 Zumo Shield schematic diagrams (183k pdf)

- v1.2 Zumo Shield schematic diagrams (449k pdf)

- Original Zumo Shield schematic diagrams (121k pdf)

Dimensions

A basic dimension diagram for the Zumo Shield is available as a PDF:

- v1.3 Zumo Shield dimension diagram (657k pdf)

- v1.2 Zumo Shield dimension diagram (467k pdf)

Dimensions that are not included in the above diagram can be measured from the following DXFs, which show the board outline along with the sizes and locations of all of the holes on the board:

- v1.3 Zumo Shield drill guide (219k dxf)

- v1.2 Zumo Shield drill guide (214k dxf)

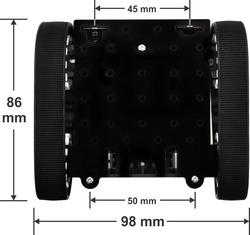

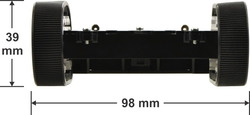

The following pictures show the approximate dimensions of the Zumo chassis that the Zumo Shield mounts on:

|

|

5. Arduino pin assignment table

| Digital pins | Zumo Shield function | Notes/alternate functions |

|---|---|---|

| 0 | digital I/O | RX for programming and serial communication on Uno and older Arduinos |

| 1 | digital I/O | TX for programming and serial communication on Uno and older Arduinos |

| 2 | digital I/O (front expansion) | I²C SDA on Leonardo and A-Star 32U4 Prime |

| 3 | digital I/O | optional jumper to buzzer control line for Uno and older Arduinos I²C SCL on Leonardo and A-Star 32U4 Prime |

| 4 | digital I/O (front expansion) | |

| 5 | digital I/O (front expansion) | |

| 6 | digital I/O | optional jumper to buzzer control line for Leonardo and A-Star 32U4 Prime |

| 7 | right motor direction control line | |

| 8 | left motor direction control line | |

| 9 | right motor PWM control line | |

| 10 | left motor PWM control line | |

| 11 | digital I/O (front expansion) | |

| 12 | digital I/O | user pushbutton (pressing pulls low) |

| 13 | digital I/O | yellow user LED (high turns LED on) |

| Analog pins | Zumo Shield function | Notes/alternate functions |

|---|---|---|

| A0 | analog input and digital I/O (front expansion) | |

| A1 | analog input and digital I/O (front expansion) | optional jumper to battery level voltage divider |

| A2 | analog input and digital I/O (front expansion) | |

| A3 | analog input and digital I/O (front expansion) | |

| A4 | analog input and digital I/O (front expansion) | I²C SDA on Uno and older Arduinos |

| A5 | analog input and digital I/O (front expansion) | I²C SCL on Uno and older Arduinos |

6. Zumo Shield Arduino library

Our Zumo Shield Arduino library makes it easy to get started writing Arduino sketches to control your Zumo. A link to download the library and installation instructions can be found on the library’s GitHub page. The Zumo Shield Arduino library documentation provides detailed information about the library, and the library comes with several example sketches.

If you are using version 1.6.2 or later of the Arduino software (IDE), you can use the Library Manager to install this library:

- In the Arduino IDE, open the “Sketch” menu, select “Include Library”, then “Manage Libraries…”.

- Search for “ZumoShield”.

- Click the ZumoShield entry in the list.

- Click “Install”.

If this does not work, you can manually install the library:

- Download the latest release archive from GitHub and decompress it.

- Rename the folder “zumo-shield-arduino-library-master” to “ZumoShield”.

- Move the “ZumoShield” folder into the “libraries” directory inside your Arduino sketchbook directory. You can view your sketchbook location by opening the “File” menu and selecting “Preferences” in the Arduino IDE. If there is not already a “libraries” folder in that location, you should make the folder yourself.

- After installing the library, restart the Arduino IDE.

After you install the ZumoShield library, you can learn more about it by trying the included example sketches and by reading the Zumo Shield Arduino library documentation.

The Zumo Shield Arduino library includes the following parts:

ZumoMotors

ZumoMotors provides functions for PWM-based speed (and direction) control of the two motors on the Zumo with the onboard DRV8835 dual motor driver. On Arduinos with ATmega328P, ATmega168, and ATmega32U4 microcontrollers (which include the A-Star 32U4 Prime, Arduino Leonardo, Arduino Uno, and most older Arduinos), the motor control functions use hardware PWM outputs from Timer1 to generate pulse width modulation at a 20 kHz frequency. (See Section 3 for more details about the motor driver and its connections.)

If you accidentally soldered a motor to the Zumo Shield backwards (opposite the orientation indicated in the assembly instructions), you can simply call flipLeftMotor(true) and/or flipRightMotor(true) to make the motors behave consistently with the directions in your code.

ZumoBuzzer

ZumoBuzzer provides functions that allow various sounds to be played on the buzzer of the Zumo Shield, from simple beeps to complex tunes. (See Section 3 for more details about the buzzer and Section 3.c for an explanation of the buzzer control jumper settings.)

ZumoBuzzer is fully compatible with the OrangutanBuzzer functions in the Pololu AVR C/C++ Library, so any melodies written for OrangutanBuzzer functions will also work with ZumoBuzzer functions.

ZumoReflectanceSensorArray

ZumoReflectanceSensorArray provides a set of functions for reading reflectance values from a Zumo reflectance sensor array. See Section 2.c for more information on the Zumo reflectance sensor array.

This depends on QTRSensors. The ZumoReflectanceSensorArray class is a subclass of QTRSensorsRC. The functions provided by QTRSensorsRC can also be used on the ZumoReflectanceSensorArray class, and are documented in the Arduino Library for the Pololu QTR Reflectance Sensors document.

ZumoIMU

ZumoIMU provides functions for configuring and reading the inertial sensors on the Zumo Shield. See Section 3.d for more details about the inertial sensors.

The library also includes copies of several other Arduino libraries:

QTRSensors

QTRSensors interfaces with Pololu QTR reflectance sensors. Since the Zumo reflectance sensor array has the same interface as the QTR RC reflectance sensors, the ZumoReflectanceSensorArray library uses QTRSensors to read the sensor array.

PololuBuzzer

PololuBuzzer enables playing notes and songs on a buzzer. For boards based on the ATmega328P, this library uses Timer 2 and pin 3 (PD3/OC2B). For boards based on the ATmega32U4, this library uses Timer 4 and pin 6 (PD7/OC4D). This library will conflict will other libraries that use the same timer or pin.

Pushbutton

Pushbutton provides a set of functions that are useful for detecting and debouncing pushbutton presses. While the most obvious application of this library is to work with the Zumo Shield’s user pushbutton on digital pin 12, this library can be used as a general-purpose library for interfacing many types of buttons and switches to an Arduino, even without a Zumo Shield.

7. Example sketches

These examples demonstrate how to program an Arduino-controlled Zumo to perform more complex and interesting tasks. The source files for the examples are included in the download for the Zumo Shield Arduino Library. Once the library is installed, the examples can be accessed in the Arduino environment under File > Examples > ZumoShield.

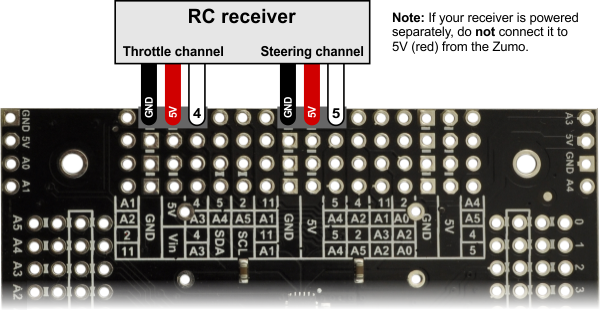

7.a. RC Zumo

By connecting an RC receiver and running this example sketch, you can turn your Zumo into a radio-controlled vehicle. With the Zumo Shield Arduino library installed, the sketch file can be opened in Arduino by selecting File > Examples > ZumoShield > RCControl.

|

A Zumo robot with an RC receiver attached to make a radio-controlled vehicle. |

|---|

An easy way to connect the receiver to the Zumo Shield is to solder two 1×3 male header strips to the locations shown in the diagram below, then plug in a pair of standard servo cables between the receiver and the Zumo Shield. (If your receiver has a separate power source, you should only connect the signal and ground wires between it and the Zumo.)

|

Diagram of an RC receiver connected to pins on a Zumo Shield. |

|---|

This program uses Arduino’s PulseIn library to read the signals from the receiver. By default, it assumes the throttle and steering channels are connected as the diagram shows on pins 4 and 5, respectively. The signals from the two channels are mixed to determine the left and right motor speeds, allowing for more intuitive control.

7.b. Simple border-detecting sumo robot

Adding sensors to the Zumo allows it to sense and react to its surroundings. In a sumo competition where two robots try to push each other out of a circular ring, it is important for a robot to be able to detect the border of the ring so it can avoid driving over the edge. Since standard robot sumo rings are colored black with a white border around the edge, infrared reflectance sensors like our QTR sensors are great for this purpose. The Zumo Reflectance Sensor Array conveniently mounts six of these sensors in a module designed to plug directly into the front expansion header of the Zumo Shield (note: the pre-assembled version of the Zumo robot ships with this reflectance sensor array already installed).

|

|

This example demonstrates how to program an Arduino-controlled Zumo equipped with a reflectance sensor array to drive around and stay within a sumo ring. Note that it only uses the two outermost sensors on the array, which are sufficient for border detection. With the Zumo Shield Arduino library installed, the sketch file can be opened in Arduino by selecting File > Examples > ZumoShield > BorderDetect.

You might need to edit a few things in this sketch to make it work well with your Zumo:

- If one or both of your motors have been connected backwards, uncomment the

flipLeftMotororflipRightMotorlines to correct their directions. - Adjust the speeds and duration definitions at the top of the sketch. Generally, lower speeds and shorter durations should work better with faster motors, while higher speeds and longer durations should be more appropriate for slower motors. We found that these default values worked well with a Zumo using 75:1 HP motors.

- Finally, the sensor reading threshold used to differentiate between black and white surfaces,

QTR_THRESHOLD, might need to be changed to suit your lighting and ring conditions.

Upload the sketch to an Arduino mounted on a Zumo, place the Zumo on a sumo ring (or a similar large dark surface with a light border), and press the user pushbutton. Be ready to catch the Zumo in case it drives off the ring! If everything works right, the Zumo should sound a countdown with its buzzer and then start driving forward until it detects the ring border; it should then back up, turn, and continue. If not, try adjusting some of the parameters as described above. Here are some specific troubleshooting tips:

- If the Zumo overshoots the ring border, try lowering

FORWARD_SPEED(especially if it is going very fast) or reducingQTR_THRESHOLD. - If the Zumo stops at the border but turns too much or not enough before continuing, adjust

TURN_SPEEDand/orTURN_DURATION. - If you do not hear any sound from the buzzer, make sure you have the buzzer control jumper configured correctly for your Arduino.

The ability to wander around while staying inside a sumo ring is enough to allow a Zumo to compete as a basic sumo robot, but a more advanced robot might be able to detect its opponent and drive toward it directly. As a next step, you might consider adding more sensors, such as range finders, to allow the Zumo to find its opponent instead of relying on luck to make contact.

7.c. Collision-detecting sumo robot

This example extends the simple border-detecting sumo robot example described in the previous section, making use of the the Zumo Shield’s 3-axis accelerometer (described in section Section 3.d) to detect collisions. With the Zumo Shield Arduino library installed, the sketch file can be opened in Arduino by selecting File > Examples > ZumoShield > SumoCollisionDetect.

This program uses the X and Y components of the accelerometer’s measurements to determine when it has made contact with an adversary robot in a sumo competition. When it detects contact, the Zumo speeds up, which should allow it to either more effectively push the opponent out of the ring or to escape the opponent if it collided at an undesired angle (from the rear or side). To read more about how this program works, please see the comments contained in SumoCollisionDetect.ino.

7.d. Line follower

This example program demonstrates how a Zumo with a reflectance sensor array can be programmed to follow lines and run a line-following course. With the Zumo Shield Arduino library installed, the sketch file can be opened in Arduino by selecting File > Examples > ZumoShield > LineFollower.

This line follower implementation is very similar to our line following example for the 3pi robot, and the concepts and strategies involved are explained in detail in Section 7 of the 3pi robot user’s guide.

7.e. Maze solver

This example program demonstrates how a Zumo with a reflectance sensor array can be programmed to solve a line maze. With the Zumo Shield Arduino library installed, the sketch file can be opened in Arduino by selecting File > Examples > ZumoShield > MazeSolver.

This maze solver implementation is very similar to our maze solving example for the 3pi robot, and the concepts and strategies involved are explained in detail in Section 8 of the 3pi robot user’s guide.

7.f. Coordinating turns with the compass

This example program demonstrates using the Zumo Shield’s 3-axis magnetometer (described in section Section 3.d) to help the Zumo coordinate ninety-degree turns and drive in squares. With the Zumo Shield Arduino library installed, the sketch file can be opened in Arduino by selecting File > Examples > ZumoShield > TurnWithCompass.

Because the batteries, motors, and motor current affect the z axis of the magnetometer much more strongly than the x and y axes, this program calculates the Zumo’s orientation using only the x and y readings from the magnetometer, assuming that the robot is always level. In order to prevent external, locally varying magnetic fields (e.g. from rebar in a concrete floor) from affecting the Zumo’s navigation too much, the program measures the magnetic heading before each turn, then turns ninety degrees relative to that heading.

8. Controlling a servo

This section explains how to control a hobby RC servo from an Arduino Uno, Arduino Leonardo, or A-Star 32U4 Prime that is connected to the Zumo Shield. The Arduino IDE includes a Servo library that generates the pulses needed to control an RC servo. However, this servo library conflicts with ZumoMotors in that both rely on Timer 1. Instead, you will need to do something special to get servo control working.

To control a servo with an Arduino Uno, see Section 8.a. To control a servo with an Arduino Leonardo or A-Star 32U4 Prime, see Section 8.b.

8.a. Controlling a servo with an Arduino Uno

The example Arduino Uno code below shows how to control a single servo using Timer 2. Because it uses Timer 2 instead of Timer 1, this code does not interfere with ZumoMotors, but it will interfere with ZumoBuzzer, so you will not be able to use this and the buzzer at the same time. You can integrate this code with other code that drives the motors.

/** Arduino Uno Timer 2 Servo Example

This example code for the Arduino Uno shows how to use Timer 2 on

the ATmega328P to control a single servo. This can be useful for

people who cannot use the Arduino IDE's Servo library. For

example, ZumoMotors uses the same timer as the Servo

library (Timer 1), so the two libraries conflict.

The SERVO_PIN macro below specifies what pin to output the

servo on. This pin needs to be connected to the signal input

line of the servo. The Arduino's GND needs to be connected to

the ground pin of the servo. The servo's ground and power pins

need to be connected to an appropriate power supply.

*/

// This line specifies what pin we will use for sending the

// signal to the servo. You can change this.

#define SERVO_PIN 11

// This is the time since the last rising edge in units of 0.5us.

uint16_t volatile servoTime = 0;

// This is the pulse width we want in units of 0.5us.

uint16_t volatile servoHighTime = 3000;

// This is true if the servo pin is currently high.

boolean volatile servoHigh = false;

void setup()

{

servoInit();

}

void loop()

{

servoSetPosition(1000); // Send 1000us pulses.

delay(1000);

servoSetPosition(2000); // Send 2000us pulses.

delay(1000);

}

// This ISR runs after Timer 2 reaches OCR2A and resets.

// In this ISR, we set OCR2A in order to schedule when the next

// interrupt will happen.

// Generally we will set OCR2A to 255 so that we have an

// interrupt every 128 us, but the first two interrupt intervals

// after the rising edge will be smaller so we can achieve

// the desired pulse width.

ISR(TIMER2_COMPA_vect)

{

// The time that passed since the last interrupt is OCR2A + 1

// because the timer value will equal OCR2A before going to 0.

servoTime += OCR2A + 1;

static uint16_t highTimeCopy = 3000;

static uint8_t interruptCount = 0;

if(servoHigh)

{

if(++interruptCount == 2)

{

OCR2A = 255;

}

// The servo pin is currently high.

// Check to see if is time for a falling edge.

// Note: We could == instead of >=.

if(servoTime >= highTimeCopy)

{

// The pin has been high enough, so do a falling edge.

digitalWrite(SERVO_PIN, LOW);

servoHigh = false;

interruptCount = 0;

}

}

else

{

// The servo pin is currently low.

if(servoTime >= 40000)

{

// We've hit the end of the period (20 ms),

// so do a rising edge.

highTimeCopy = servoHighTime;

digitalWrite(SERVO_PIN, HIGH);

servoHigh = true;

servoTime = 0;

interruptCount = 0;

OCR2A = ((highTimeCopy % 256) + 256)/2 - 1;

}

}

}

void servoInit()

{

digitalWrite(SERVO_PIN, LOW);

pinMode(SERVO_PIN, OUTPUT);

// Turn on CTC mode. Timer 2 will count up to OCR2A, then

// reset to 0 and cause an interrupt.

TCCR2A = (1 << WGM21);

// Set a 1:8 prescaler. This gives us 0.5us resolution.

TCCR2B = (1 << CS21);

// Put the timer in a good default state.

TCNT2 = 0;

OCR2A = 255;

TIMSK2 |= (1 << OCIE2A); // Enable timer compare interrupt.

sei(); // Enable interrupts.

}

void servoSetPosition(uint16_t highTimeMicroseconds)

{

TIMSK2 &= ~(1 << OCIE2A); // disable timer compare interrupt

servoHighTime = highTimeMicroseconds * 2;

TIMSK2 |= (1 << OCIE2A); // enable timer compare interrupt

}

8.b. Controlling a servo with an Arduino Leonardo or A-Star 32U4 Prime

It is possible to modify the Servo library that comes with the Arduino IDE to use Timer 3 instead of Timer 1 on the Arduino Leonardo or A-Star 32U4 Prime. The modified Servo library does not interfere with ZumoMotors, making it possible to simultaneously control servos and the motors.

Warning: The modifications described here will affect any sketch for the Arduino Leonardo or A-Star that uses the Servo library.

- First, you will need to locate the Arduino IDE’s Servo library, and find the file inside it named ServoTimers.h. For the 1.6.x versions of the IDE, this file can be found in libraries/Servo/src/avr/ServoTimers.h. If you are using Mac OS X, you will need to right-click on the Arduino IDE icon and select “Show Package Contents” to see the files inside.

- Open ServoTimers.h in a text editor.

- Locate the following lines of code in ServoTimers.h:

#elif defined(__AVR_ATmega32U4__) #define _useTimer1 typedef enum { _timer1, _Nbr_16timers } timer16_Sequence_t ; - The lower two lines of code specify that the library should use Timer 1. To use Timer 3 instead, just change

_useTimer1to_useTimer3and_timer1to_timer3. - Save the file.

The Arduino IDE will automatically incorporate your modifications to the Servo library. The next time you compile a sketch for the Arduino Leonardo or A-Star that uses the Servo library, it will use Timer 3 instead of Timer 1.