Pololu Blog »

Pololu Blog (Page 54)

Welcome to the Pololu Blog, where we provide updates about what we and our customers are doing and thinking about. This blog used to be Pololu president Jan Malášek’s Engage Your Brain blog; you can view just those posts here.

Popular tags: community projects new products raspberry pi arduino more…

Last Call: Black Friday/Cyber Monday Sale

Less than 12 hours to go for our Black Friday/Cyber Monday sale! Manufacturing and shipping are working hard to make your robot parts and ship them out. If you already placed an order, thank you! Customers who ordered earlier in the sale have already started to receive their packages Continued…

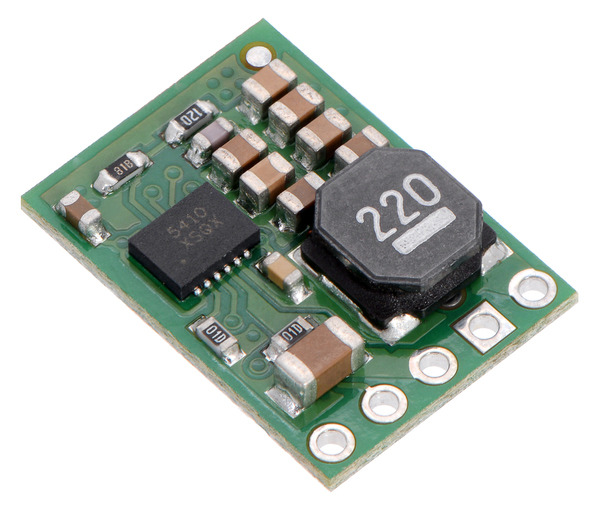

New products: D24V10Fx 1 A step-down voltage regulators

We’ve just released a new family of D24V10Fx step-down voltage regulators. These buck regulators are very similar to the D24V5Fx regulator family we introduced in March, but they use the Intersil ISL85410 regulator IC – a higher-current relative of the ISL85415 on the D24V5x – that allows them to output twice as much current (up to 1 A). The D24V10Fx family is available in five different versions with fixed output voltages of 3.3V, 5V, 6V, 9V, and 12V.

Like their 500 mA counterparts, the D24V10Fx regulators operate with input voltages as high as 36 V at typical efficiencies of 80% to 95%. They feature the same power-save mode to improve efficiency at light loads, along with low dropout voltages and integrated protection against over-temperature and over-current conditions. All this makes them a good choice for powering applications where input voltage and operating current might vary over a wide range.

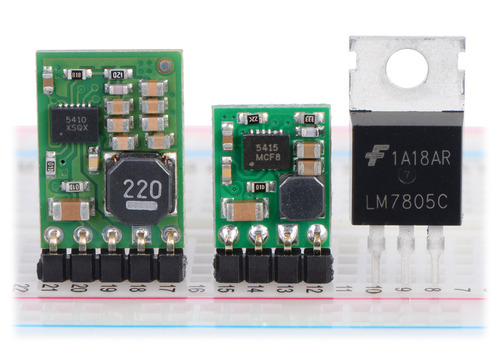

The slightly larger size of these new regulator boards (0.5″ × 0.7″ × 0.14″; 18 mm × 13 mm × 3.5 mm) makes room for a fifth pin that provides a “power good” indication (PG), but they are still not much bigger than standard through-hole linear regulators. The picture below shows a D24V10Fx, a D24V5Fx, and a 7805 voltage regulator in a TO-220 package:

|

For other regulator options, you can take a look at our full selection of step-up voltage regulators, step-down voltage regulators, and step-up/step-down voltage regulators.

Khan Academy interactive continuous rotation servo demo

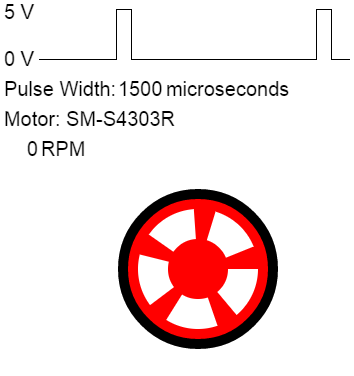

|

Khan Academy user mbbackus created a demo that allows users to visualize the effects of sending different pulse widths to the SM-S4303R and Parallax continuous rotation servos. (You can use the up and down arrow keys to change the pulse width, and more instructions can be found as comments in the code.)

For those who are interested, you can learn more about standard RC servo pulses in this series of blog posts about hobby servos.

You can see the demo on its Khan Academy page.

Black Friday Sale at Adafruit

Our friends at Adafruit are holding a Black Friday sale today, offering 15% off everything in stock plus extra free items for orders above certain amounts.

You can find the details on the Adafruit blog.

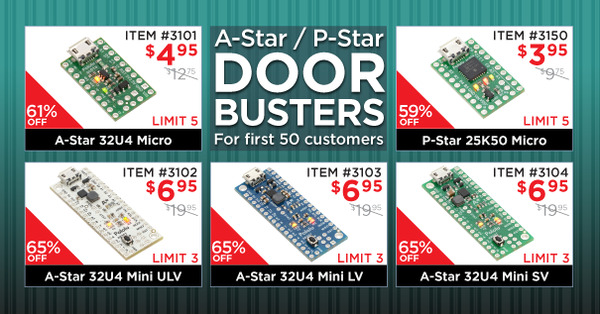

Black Friday/Cyber Monday Sale: check out all the deals!

You can now find all of our sale details, including a full list of the sale items, on our Black Friday/Cyber Monday sale page. The first doorbuster deals go live in less than 12 hours!

Coming soon: Pololu Black Friday/Cyber Monday Sale

Our annual Black Friday/Cyber Monday sale is less than a week away! We have put up some of the special offers on the Black Friday/Cyber Monday sale page. Stay tuned for more details!

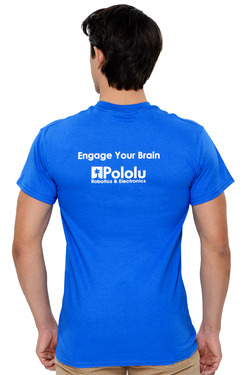

New products: Pololu T-shirts

We have a new batch of T-shirts available, just in time for winter! These shirts are very similar to the ones we released in 2012, featuring a printed circuit board (PCB) design in the shape of the Pololu logo on the front and the Pololu slogan “Engage Your Brain” on the back.

|

|

The shirts are available in a variety of youth and adult sizes, and this time we have two new colors available in addition to our standard royal blue: cardinal red and charcoal gray.

|

|

You can find our full selection in our T-shirts category.

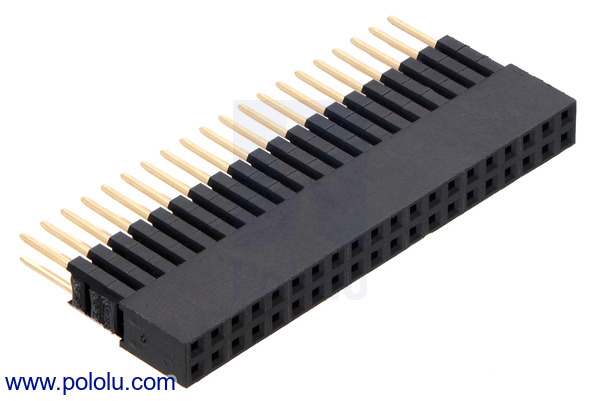

New products: Stackable headers for the Raspberry Pi

|

Stackable 0.100″ Female Header: 2×20-pin, Straight. |

|---|

We now have special extended, stackable female headers for the Raspberry Pi:

- Stackable 0.100″ Female Header with Extra 0.3″ Spacer: 2×20-pin, Straight

- Stackable 0.100″ Female Header: 2×20-pin, Straight

- Stackable 0.100″ Female Header with Extra 0.2″ Spacer: 2×13-pin, Straight

- Stackable 0.100″ Female Header: 2×13-pin, Straight

The 2×20 versions work with the Raspberry Pi Model B+ (and the just-released A+), while the 2×13 versions match the I/O header on the older Raspberry Pi Models A and B.

See our Raspberry Pi category for our full selection of Raspberry Pi accessories.

ToyCollect: A robot that collects toys from hard-to-reach places

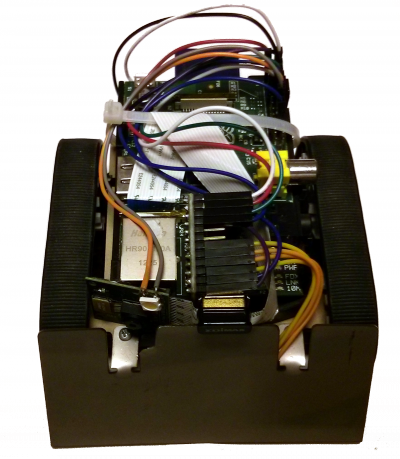

|

The people at Seewald Solutions posted about their Raspberry Pi-based robot they call ToyCollect. Inspired by the creator’s daughter, who hides her toys under the couch, the robot is controlled via Android and can be driven under the couch to allow the user to view the hidden toys via a Raspberry Pi camera module and retrieve them. Along with a Raspberry Pi, the ToyCollect robot uses a Zumo Chassis Kit, 100:1 Micro Metal Gearmotors HP, Qik 2sv1 Dual Serial Motor Controller, and a Zumo blade to push the toys. The video below shows the robot in action (in German; subtitles available):

For more information, including the source code and instructions for building your own ToyCollect robot, see the ToyCollect post on the Seewald Solutions website.

New product: Parallax BASIC Stamp Discovery Kit (USB)

We are now carrying the USB version of the BASIC Stamp Discovery Kit. Please see the product page for more information.