Pololu Blog »

New RoboClaw and MCP motor controllers from Basicmicro

|

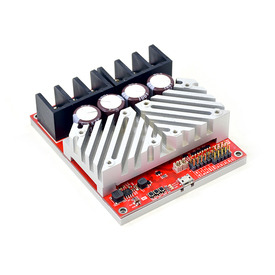

RoboClaw 2×60AHV, 60VDC Motor Controller. |

|---|

We are excited to offer eight new powerful motor controllers from Basicmicro (formerly Ion Motion Control):

- RoboClaw 2x60AHV, 60VDC

- RoboClaw 2x160A, 60VDC

- MCP233 Dual 30A, 34VDC

- MCP236 Dual 30A, 60VDC

- MCP263 Dual 60A, 34VDC

- MCP266 Dual 60A, 60VDC

- MCP2163 Dual 160A, 34VDC

- MCP2166 Dual 160A, 60VDC

The two new RoboClaws bring our total selection of those to nine versions. Unlike the other RoboClaws, which have a maximum operating voltage of 34 V, these new RoboClaws and some of the new MCP controllers can work up to 60 V and deliver a continuous 60 A or 120 A per channel, making them the most powerful motor controllers we carry by far.

|

|

|

The six MCP products are from Basicmicro’s rugged new line of MCP Advanced Motor Controllers, which are optionally programmable via a built-in scripting language and support a variety of interfaces, including USB serial, TTL serial, RS-232 serial, CAN bus, RC hobby servo pulses, and analog voltages. Here is a summary of the key features of the MCP:

- Simple bidirectional control of two brushed DC motors

- 10–34 V or 10–60 V operating supply range, depending on controller model

- 30 A to 160 A maximum continuous current output, depending on controller model

- Channel bridging allows control of a single motor with double the current capability

- Automatic current limiting reduces duty cycle when temperature exceeds 85° C

- Six communication or control options:

- USB serial interface (virtual COM port)

- 3.3 V logic-level (TTL) serial interface for direct connection to microcontrollers or other embedded controllers

- RS-232 serial interface

- CAN bus interface supporting CANopen protocol as master or slave device

- Hobby radio control (RC) pulse width interface for direct connection to an RC receiver or RC servo controller

- Analog voltage (0 V to 5 V) interface for direct connection to potentiometers and analog joysticks

- Automatic control switching with user-defined priority settings

- I²C interface accessible by user script

- Up to 20 user-defined input pins for control, feedback, or scripting, depending on controller model

- All inputs are 15 V tolerant for interfacing to industrial devices such as PLCs

- Up to 8 user-defined open-drain output pins (40 V max) for driving auxiliary loads, depending on controller model

- Multiple feedback options for PID closed-loop control:

- Speed or position control with quadrature encoders, up to 21 million encoder pulses per second

- Position control with analog encoders or potentiometers

- (Open-loop control with no feedback also available)

- Programmable with built-in user scripting language

- Screw terminals for quick connect/disconnect

- Configurable via USB connection and PC software

- Regenerative braking

- Tolerates high-speed direction changes

- 5 V BEC can power external logic

- Battery monitoring and under-voltage cutoff protects batteries from over-discharging

- Fully enclosed for protection

- Conduction plate for cooling on bottom of enclosure