Pololu Blog »

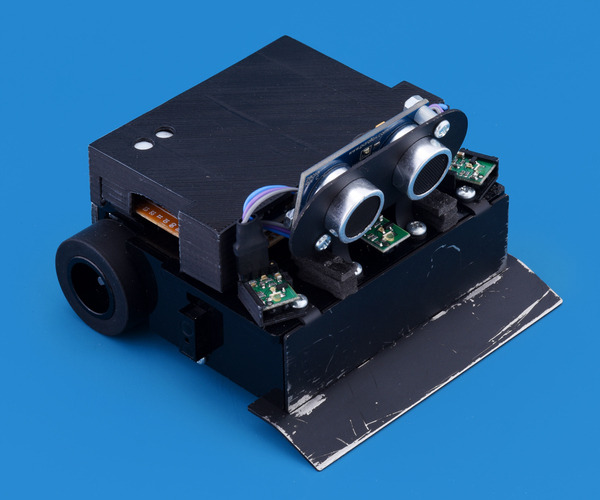

Brandon's mini sumo robot: Black Mamba

Before I started designing my entry into this year’s LVBots mini sumo competition, I watched several videos of other competitions. I noticed a majority of the victories came from engaging the opponent from the side or back; a pattern I also noticed during the last LVBots mini sumo competition. For that competition, I made a robot that used a blade and sensors on the front and back of the robot (basically making the robot have two fronts and no back). However, my strategy in that competition was to roam the ring and search for the opponent, which I suspect increased the chances of the opponent engaging from a suboptimal angle. This time, I wanted to try having my robot spin in place looking for the opponent and striking once it was found. This ultimately resulted in my newest mini sumo robot, Black Mamba. For those unfamiliar, a black mamba is a snake with a reputation for being highly aggressive and is one of the longest and fastest-moving snakes in the world. A black mamba’s venom is highly toxic, and it is capable of striking at considerable range, occasionally delivering a series of bites in rapid succession. Black Mamba is also Kobe Bryant’s self-appointed nickname (yes, I am a Lakers fan).

|

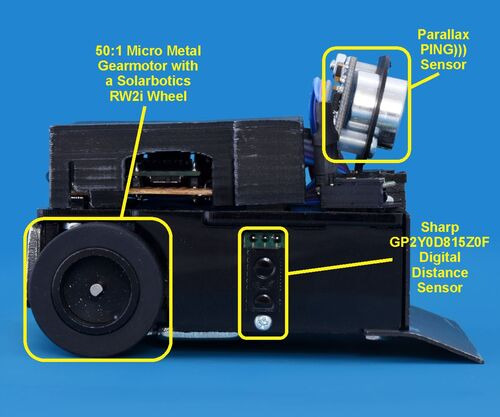

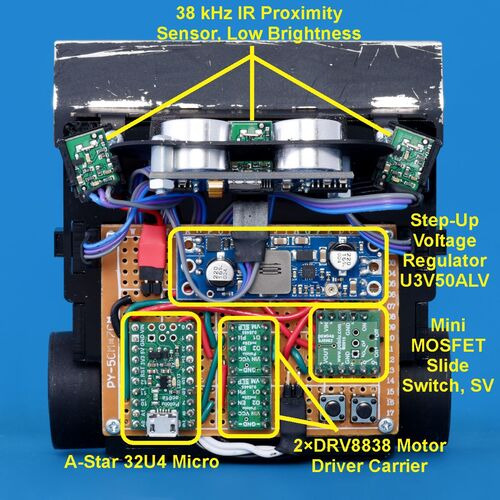

Black Mamba uses three varieties of sensors. For longer range detection, I used a Parallax Ping))) Ultrasonic Sensor on the front of my robot. Last competition, I used all infrared (IR) sensors, which had trouble detecting robots that had mostly black surfaces to reduce reflectivity, especially at farther distances. The Ping))) sensor does not depend on the IR reflectivity of the object, so I did not have the same problem this time. However, I noticed that the detection angle of the Ping))) sensor was wider than I had hoped, and Black Mamba could not reliably hit the target (it would often end up next to it instead). To address this, I added an IR Proximity Sensor on each side of the robot (facing forward and mounted with a custom 3D printed bracket). Because these particular sensors can be sensitive, I got better results by disabling the emitters on these two sensors and using an additional one in the middle that functioned as the emitter. This worked fairly well to correct the problem, since once the target was close enough, the IR Proximity Sensors would take priority.

|

The robot is powered from 3 AAA batteries held by a battery holder mounted inside of the custom laser-cut acrylic enclosure. The voltage from the batteries is fed into a Mini MOSFET Slide Switch, which then feeds it into a U3V50ALV Adjustable Step-Up Voltage Regulator. The output of that regulator can be adjusted between 4 V and 12 V using the onboard potentiometer. This allows me to change the voltage to my motors later if I need more power. The motors I chose are 50:1 HP Micro Metal Gearmotors since they have a good balance of speed and torque for mini sumo. The RW2i Wheels from Solarbotics offer plenty of traction and are directly compatible with the Micro Metal Gearmotors. I had two DRV8838 Motor Driver Carriers from a previous project that I repurposed for Black Mamba. An A-Star 32U4 Micro processes all of the sensor data and controls the motors. I picked the A-Star 32U4 Micro mainly because of its compact size, but it also has more than enough digital pins accessible to run the robot and add a few extra buttons for usability. All of the electronics are mounted to a prototyping PCB to keep it organized. I made a clip-on 3D printed housing for the electronics to keep them safely concealed. As a final touch, I added as many small wheel weights as I could to get the weight close to the 500 g maximum allowed by the rules of the competition.

|

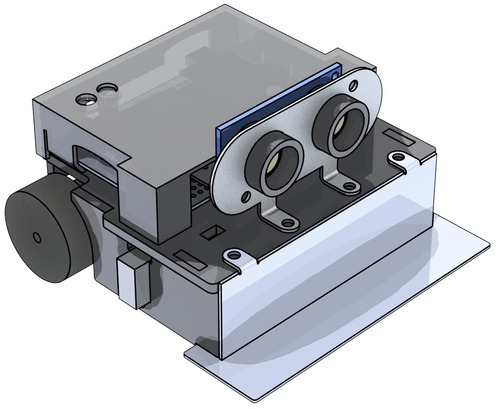

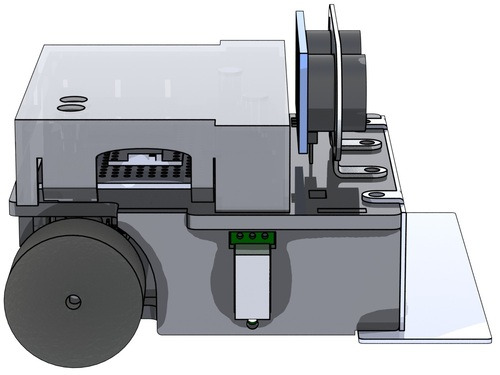

Once I selected all of my electronics (aside from the IR Proximity Sensors since they were added later after testing) and components, I made a 3D CAD model of the robot before laser cutting any of the pieces. When making the CAD model, I found it helpful to start with the largest or most significant part. In this case, I started with the motors and I chose to put them as far toward the rear of the chassis as I could, which left me room for the battery holder. I knew I wanted the batteries low and towards the back. The model helped get all of the joints lined up correctly as well as make sure the robot would fit inside of the size constraints (10cm × 10cm). The pictures below are renders taken from SolidWorks.

|

|

This competition had several very close matches. Black Mamba finished in fourth place, but two of the matches (including one against the eventual champion Roku) came down to slow motion instant replay, and the opponent came out victorious in both cases. Black Mamba was even able to flip one of these opponents upside down before ultimately hitting the ground first. You can see these close losses at the 0:55 and 4:40 marks of the “LVBots Mini-Sumo Competition August 2015” YouTube video, which is also available on the Video: LVBots August 2015 mini-sumo competition blog post that summarizes the results.

5 comments

Very nice product, can we also rotate it left and right?

It is not entirely clear to me what you mean, but if you are asking if the robot can turn, the answer is yes. Black Mamba is a differential wheeled robot. In short, since it uses two separate motors (one on each side of the robot), running them at different speeds causes the robot to turn, so running one motor forwards and the other backwards at the same rate causes it to turn in place.

If this is not what you are asking, can you try rephrasing your question?

-Brandon

Yes, i am asking about robot turning. Thanks for your appreciation Brandon.

I used DC motors from Pololu before (10:1 ratio for line follower robots and I was extremely pleased with the results) so I'm quite familiar with them, but it's the first time I'm trying to build a mini-sumo robot and I don't know what gear ratio to choose. I was thinking of trying 150:1 (200rpm, 40 oz-in) or even 210:1 (140rpm, 50 oz-in), but my fear is that these motors are going to be too slow, despite being very powerful.

Any advice would be greatly appreciated.

Thanks in advance.

Costi.

:)

You might find our "Force and Torque" blog helpful when selecting the right gearmotor for your robot. One key factor to consider is that the speed and pushing force of your robot will depend on the size of your wheels. For example, a larger diameter wheel will cause the robot to travel faster, but have less pushing force. The actual pushing force you get could also be limited by traction, so using too high of a gear ratio for the extra torque might not be as beneficial at some point since your wheels/treads will likely start slipping on the surface.

For reference, we typically recommend the 50:1, 75:1, or 100:1 HP micro metal gearmotors for use with our Zumo robots, which is often used in mini sumo competitions. For a slower Zumo that has the potential to deliver more torque, the 100:1 HP (or the 100:1 HPCB) micro metal gearmotor would be a good choice. I probably wouldn't recommend going too much higher than that since the reduced speed would likely be hard obstacle to overcome, and even in head-to-head battles, slipping could start limiting your pushing force, so you might not be able to effectively use the increased torque.

Brandon