Services »

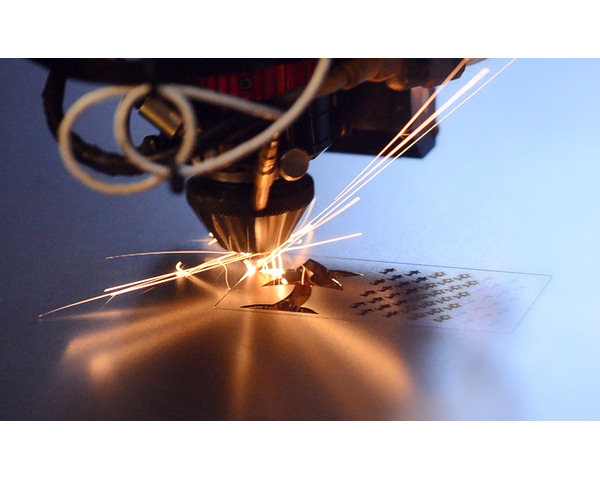

Custom Laser Cutting Service

Our laser cutting service is ideal for making custom parts out of various sheet materials. Capabilities include cutting, scoring, and engraving with our laser cutters, plus color UV-printing. Pricing starts at $25, and most orders ship in three business days. We also offer expedited services, up to our same-day service; local customers can pick up parts the same day, or have them shipped to your door the very next day!

| Description | Specs (0) | Pictures (45) | Resources (7) | FAQs (6) | On the blog (38) | Distributors (0) |

|---|

- How should I set up the layers in my CAD/DXF/DWG file?

- In general, putting all CUT LINES on a single layer is the best for our process. We do prefer that you use a second layer for all of your annotations and a third layer for your engraving, but we can work with annotations and engravings on the same layer as the cut lines as well. All layers should be unlocked and editable. Please delete layers that aren’t needed (do not make them invisible). These layer restrictions are only to make it easier for the person preparing your file for laser cutting and quoting; the more closely you follow our guidelines, the faster we can provide a quote and cut your parts.

- What is the size reference in my laser cutting file for? Do I really need one?

- We need a size reference in every laser cutting file to double-check that the rest of your file did not get scaled up or down by the various programs that you might have used, and that we use. For every laser cutting file you submit, please do include some type of size reference. A 1-inch square (or 1-cm square) labeled, “1-inch square size reference” would be the best. We will not include the size reference in your final cut or in your PDF proof (unless you note otherwise in your quote request).

- Will my special notes in my laser cutting files be accidentally cut?

Somebody always processes your original files and makes a version of it that is optimized for quoting and for laser cutting, so you don’t have to worry that we will “automatically” cut and charge you for the annotations in your file.

In general, you do not have to worry that we would cut and charge you for something you do not want: once you submit your quote request on our web site, somebody will process the request and email you a link to the quote, which will include a PDF proof of what the quote is for. If you want to order the quote, you must approve the PDF proof, first. If you notice something wrong with the proof (if there is engraving text missing, if there are annotations that we misunderstood to be engraving, if there aren’t enough of part X, etc.), there is a way for you to disapprove the PDF proof and explain how to fix the problems. The quoter will fix the problems and the cycle starts again.

- How should I provide special instructions for my laser cutting quote request?

A person will always look at your entire quote and files (nothing is ever completely automatically processed), so as long as you can clearly communicate your needs, you may include various annotations and text in your files and in the “Special instructions” text box we provide in our online quote form. If you like, you may also call us (702-262-6648) and ask for the laser cutting department to discuss your quote request (you could even note, “please wait for my call before you process this quote request” in your special instructions).

You do not have to worry that we would cut and charge you for something you do not want: once you submit your quote request on our web site, somebody will process the request and email you a link to the quote, which will include a PDF proof of what the quote is for. If you want to order the quote, you must approve the PDF proof, first. If you notice something wrong with the proof (if there is engraving text missing, if there are annotations that we misunderstood to be engraving, if there aren’t enough of part X, etc.), there is a way for you to disapprove the PDF proof and explain how to fix the problems. The quoter will fix the problems and the cycle starts again.

- How do I tell you which inside cut-outs to save and ship from my designs?

- If you want us to ship the inside cut-outs from your laser cutting job, please note that in the “special instructions” section of the quote request. If your request is somewhat complicated (“keep this one, but not that one”), you might consider using different colored lines in your file to indicate the cutouts to save, and note, “save all cutouts drawn in magenta” in the special instructions. Note that saving large areas of cut-outs might increase your shipping costs depending on their relative weights compared to your parts (you can see exactly what your shipping cost will be in step 2 of the ordering process, after you enter your shipping address, and before entering any credit card information).

- How many files do I submit for my laser cutting request?

Please submit one file per material. For example, if you have 20 parts to cut from 3mm clear acrylic, part X to cut from 6mm clear acrylic, and also part X to cut from 3mm black ABS, you would have to submit a quote with three of what we call, “designs”:

EXAMPLE QUOTE REQUEST

- Design 1: one file with 20 parts to be cut from 3mm clear acrylic

- Design 2: one file with 1 part (design X) to be cut from 6mm clear acrylic

- Design 3: one file with 1 part (design X) to be cut from 3mm black ABS

NOTES:

- You would probably submit the SAME FILE for Designs 2 and 3 unless you have different annotations in the two files. It is helpful if you note something like, “Design 2 and 3 are the same part, but just from different materials” in the special instructions section of your quote request.

- Your file for Design 1 might only have 4 different parts, with annotations explaining how many copies of each part you need (for example, “two of part A, six each of all other parts”).