Dual MC33887 Motor Driver Carrier

If you are looking to drive two DC motors running from 5-28 V and drawing up to 5 A (2.5 continuous), this compact dual carrier of Freescale’s MC33887 motor driver is just what you need. Extra features such as current sensing and over-current protection make the 33887 an excellent general-purpose motor driver.

Discontinuation Notice: This board has been replaced by the more capable dual MC33926 motor driver carrier.

| Description | Specs (13) | Pictures (3) | Resources (2) | FAQs (0) | On the blog (0) | Distributors (0) |

|---|

Discontinuation Notice: This board has been replaced by the more capable dual MC33926 motor driver carrier.

|

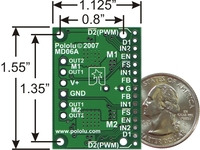

These compact dual carriers for the Freescale Semiconductor MC33887 motor driver integrated circuit are an easy way to connect two brushed DC motors running from 5 to 28 V and drawing up to 5 A (peak) each to your project. The board incorporates all of the components of the typical application diagram on page 25 of the MC33887 datasheet, plus motor-direction LEDs and a FET for reverse battery protection. All you need to add is a microcontroller or other control circuit to turn the H-Bridge on and off. For a single-motor version of this motor driver, please consider the MC33887 motor driver carrier. For a very similar motor driver that supports ultrasonic (up to 20 kHz) PWMs and a wider logic voltage range (3 – 5 V), please consider the MC33926 motor driver carrier or Dual MC33926 motor driver carrier.

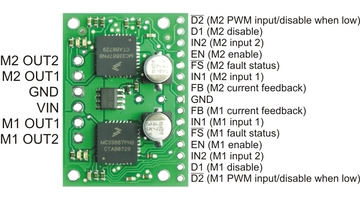

In a typical application, the power connections are made on one end of the board, and the control connections (5V logic) are made on the other end. The enable (EN) pins do not have pull-up resistors, so you must pull them to +5 V in order to wake their chips from sleep mode. The fault-status (FS, active low) output pins may be left disconnected if you do not want to monitor the fault conditions of the motor drivers; if you do connect them you must use an external pull-up resistor to pull the lines high. IN1 and IN2 control the direction of their associated motor, and D2 can be PWMed to control the motor’s speed. D2 is the “not disabled” line: it disables its motor driver when it is driven low and enables its motor driver when driven high. Whenever D1 or D2 disable a motor driver, that driver’s FS pin will be driven low. Each feedback (FB) pin outputs a voltage proportional to the H-Bridge high-side current of its associated driver, providing approximately 0.59 volts per amp of output current.

|

The dual MC33887 motor driver carrier PCB comes with two 47 uF, 35 V surface-mounted capacitors and holes for installing an additional through-hole capacitor. This third capacitor can be added in conjunction with the two surface-mount capacitors to further limit disturbances on the main power line, or it can be added in place of the two surface-mount capacitors to allow the MC33887 motor driver carrier to function at high voltages.

Note: A 15-pin male header and three 2-pin terminal blocks are included but not soldered onto the boards. No printed documentation is shipped with these items; please see the MC33887 datasheet in the resources tab for more information about the motor drivers.

MC33887 Specifications (only one active driver)

- Operating voltage: 5-28 V

- Maximum PWM frequency: 10 kHz

- Current sense: 0.59 V/A

- Time to overheat at 5 A*: 2 s

- Time to overheat at 4 A*: 21 s

- Time to overheat at 3 A*: 165 s

- Current for infinite run time*: 2.5 A

*Typical results using the single MC33887 motor driver carrier with 100% duty cycle at room temperature with no forced air flow or heat sink. The dual MC33887 motor driver has a larger PCB and hence will be more effective at drawing heat away from the motor driver chips, but driving two chips simultaneously will generate more heat and could lead to slightly reduced performance.

Real-world power dissipation considerations

The MC33887PNB motor driver used on the carrier board has a maximum current rating of 5 A continuous. However, the chip by itself will overheat at lower currents (see table above for typical values). The actual current you can deliver will depend on how well you can keep the motor driver cool. The carrier’s printed circuit board is designed to draw heat out of the motor driver chips, but performance can be improved by adding a heat sink. In our tests, we were able to use a single motor driver to deliver 5 A for a few seconds and 2.5 A continuously without overheating. These tests were conducted at 100% duty cycle; PWMing the motors will introduce additional heating proportional to the frequency.

This product can get hot enough to burn you long before the chip overheats. Take care when handling this product and other components connected to it.

Unlike other H-Bridges, the 33887 has a feature that allows it to gracefully reduce current as the current exceeds 5 A or as the chip temperature approaches its limit. This means that if you push the chip close to its limit, you will see less power to the motor, but it might allow you to avoid a complete shutdown.

Schematic Diagram

|

The diagram above shows the circuit for one of the two motor drivers. The reverse-protection MOSFET, the power input J1, and power supply capacitors C3-C5 are shared by the two channels.

People often buy this product together with:

|

TB6612FNG Dual Motor Driver Carrier |