This is a merged information page for Item #961.

View normal product page.

Pololu item #:

961

Brand:

Pololu

Status:

Active and Preferred

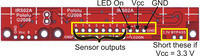

This sensor module has 8 IR LED/phototransistor pairs mounted on a 0.375" pitch, making it a great detector for a line-following robot. Pairs of LEDs are arranged in series to halve current consumption, and a MOSFET allows the LEDs to be turned off for additional sensing or power-savings options. Each sensor provides a separate digital I/O-measurable output.

Compare all products in Older QTR Sensors or

Compare all products in Older QTR Sensors or  Classic TI-RSLK Parts and Accessories.

Classic TI-RSLK Parts and Accessories.

|

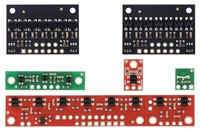

QTR-8RC reflectance sensor array. |

|---|

|

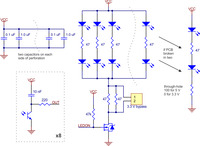

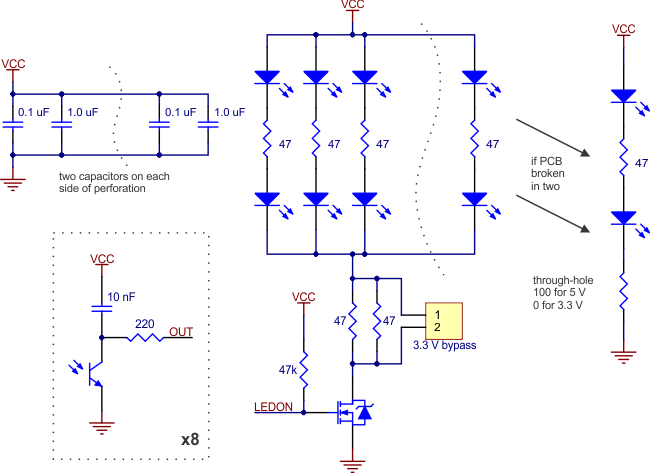

Schematic diagram of the QTR-8RC reflectance sensor array. |

|---|

|

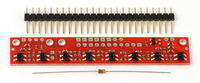

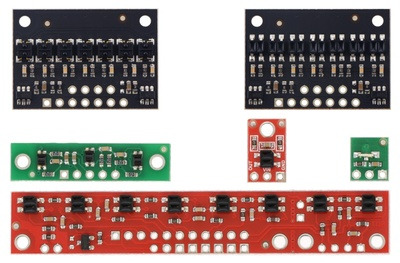

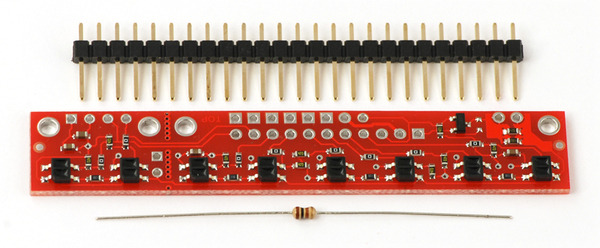

QTR-8A reflectance sensor array with included 25-pin 0.1" header strip and 100 Ohm through-hole resistor. |

|---|

|

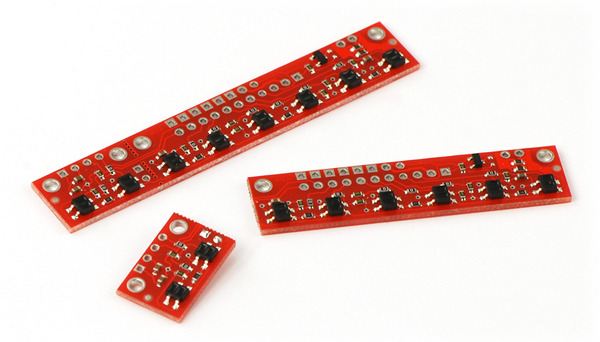

The QTR-8A reflectance sensor can separate into two smaller, functional arrays of length 2 and 6. |

|---|

|

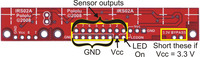

The bottom of the QTR-8A reflectance sensor array PCB, showing silkscreen labeling. |

|---|

|

Solder the included resistor to the 2-sensor array piece as shown to make the separated piece functional. |

|---|

|

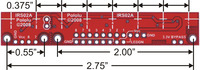

QTR-8A and QTR-8RC reflectance sensor array dimensions. |

|---|

|

QTR-8x reflectance sensor array with 8×2 connection pins labeled. |

|---|

|

QTR-8x reflectance sensor array with 11×1 connection pins labeled. |

|---|

|

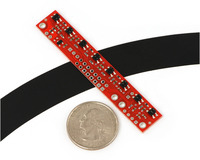

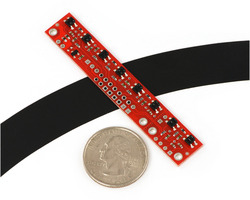

QTR-8A reflectance sensor array on a 3/4" line with a quarter for size reference. |

|---|

|

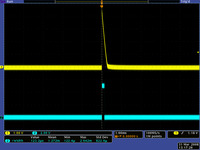

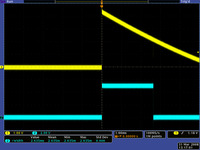

QTR-1RC output (yellow) when 1/8" above a white surface and microcontroller timing of that output (blue). |

|---|

|

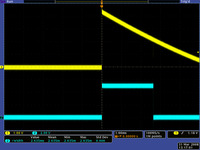

QTR-1RC output (yellow) when 1/8" above a black line and microcontroller timing of that output (blue). |

|---|

|

QTR sensor size comparison. Top row: QTRX-HD-07, QTR-HD-07; middle row: QTR-3, QTR-1, QTR-L-1; bottom row: QTR-8. |

|---|

Note: The QTR-8RC reflectance sensor array requires digital I/O lines to take readings. The similar QTR-8A reflectance sensor array is available with analog outputs, and the reflectance sensor is available individually as a QTR-1RC reflectance sensor or QTR-1A reflectance sensor.

|

The QTR-8RC reflectance sensor array is intended as a line sensor, but it can be used as a general-purpose proximity or reflectance sensor. The module is a convenient carrier for eight IR emitter and receiver (phototransistor) pairs evenly spaced at intervals of 0.375" (9.525 mm). To use a sensor, you must first charge the output node by applying a voltage to its OUT pin. You can then read the reflectance by withdrawing that externally applied voltage on the OUT pin and timing how long it takes the output voltage to decay due to the integrated phototransistor. Shorter decay time is an indication of greater reflection. This measurement approach has several advantages, especially when coupled with the ability of the QTR-8RC module to turn off LED power:

The outputs are all independent, but the LEDs are arranged in pairs to halve current consumption. The LEDs are controlled by a MOSFET with a gate normally pulled high, allowing the LEDs to be turned off by setting the MOSFET gate to a low voltage. Turning the LEDs off might be advantageous for limiting power consumption when the sensors are not in use or for varying the effective brightness of the LEDs through PWM control.

This sensor was designed to be used with the board parallel to the surface being sensed.

The LED current-limiting resistors for 5 V operation are arranged in two stages; this allows a simple bypass of one stage to enable operation at 3.3 V. The LED current is approximately 20–25 mA, making the total board consumption just under 100 mA. The schematic diagram of the module is shown below:

|

For a similar array with three sensors, consider our QTR-3RC reflectance sensor array. The sensors on the QTR-8RC are also available individually as the QTR-1RC reflectance sensor, and the QTR-L-1RC is an alternative designed to be used with the board perpendicular to the surface.

|

QTR sensor size comparison. Top row: QTRX-HD-07, QTR-HD-07; middle row: QTR-3, QTR-1, QTR-L-1; bottom row: QTR-8. |

|---|

|

QTR-1RC output (yellow) when 1/8" above a black line and microcontroller timing of that output (blue). |

|---|

The QTR-8RC module has eight identical sensor outputs that, like the Parallax QTI, require a digital I/O line capable of driving the output line high and then measuring the time for the output voltage to decay. The typical sequence for reading a sensor is:

These steps can typically be executed in parallel on multiple I/O lines.

With a strong reflectance, the decay time can be as low as several dozen microseconds; with no reflectance, the decay time can be up to a few milliseconds. The exact time of the decay depends on your microcontroller’s I/O line characteristics. Meaningful results can be available within 1 ms in typical cases (i.e. when not trying to measure subtle differences in low-reflectance scenarios), allowing up to 1 kHz sampling of all 8 sensors. If lower-frequency sampling is sufficient, substantial power savings can be realized by turning off the LEDs. For example, if a 100 Hz sampling rate is acceptable, the LEDs can be off 90% of the time, lowering average current consumption from 100 mA to 10 mA.

Our Pololu AVR library provides functions that make it easy to use these sensors with our Orangutan robot controllers; please see the QTR Reflectance Sensors section of our library command reference for more information. We also have a Arduino library for these sensors.

If you don’t need or cannot fit all eight sensors, you can break off two sensors and still use all 8 sensors as two separate modules, as shown below. The PCB can be scored from both sides along the perforation and then bent until it snaps apart. Each of the two resulting pieces will function as an independent line sensor.

|

This module ships with a 25-pin 0.1" header strip and a 100 Ohm through-hole resistor as shown below.

|

You can break the header strip into smaller pieces and solder them onto your reflectance sensor array as desired, or you can solder wires directly to the unit or use a right-angle header strip for a more compact installation. The pins on the module are arranged so that they can all be accessed using either an 11×1 strip or an 8×2 strip.

The resistor is required to make the two-sensor array functional after the original eight-sensor array is broken into two pieces. This resistor is only needed once the board has been broken.

|

Solder the included resistor to the 2-sensor array piece as shown to make the separated piece functional. |

|---|

For more information about how this sensor works, see the “How it works in detail” section of the QTR-1RC product page.

User’s guide for the QTR-8A reflectance sensor array.

Information about using the Pololu QTR reflectance sensors, including differences between A-type and RC-type sensors and sample oscilloscope screen captures of sensor outputs.

Information about installing and using the C/C++ libraries provided for use with Pololu products.

A reference to commands provided in the Pololu C/C++ and Arduino libraries for the AVR.

Step-by-step instructions for building your own line-following courses.

This is the sensor that we initially used in the Pololu QTR reflectance sensors, but we have since switched to a similar generic unit that has slightly longer range.

This DXF drawing shows the locations of all of the board’s holes.

Un guide utiliser et exploiter un senseur QTR (détecteur de ligne) (version 0.1). Note: This French translation of our QTR sensor documentation was made by our distributor MCHobby.

Matthew Phillipps ported our Arduino Library for the Pololu QTR Reflectance Sensors to the mbed platform. The Arduino library is designed to work with Pololu QTR reflectance sensors, so the mbed library should too, but Matthew points out he only tested it with the analog sensors. This library was not written and is not maintained by Pololu.

This library for Arduino makes it easy to interface with Pololu QTR Reflectance Sensors.

No FAQs available.

Customer Thomas Broughton made a line follower robot controlled by a Raspberry Pi that directly connects to a Pololu QTR-8RC reflectance sensor...

Pololu forum user Martin_H posted about his robot that plays the Tower of Hanoi with paper blocks. An RP5 chassis drives along a track, locating...

My entry for the LVBots line following competition last month was a rehash of my line following robot from last year, Pinto. Unfortunately, my...

A few weeks ago the local robotics club, LVBots, hosted a line following competition here at Pololu, and like many of the engineers here, I built a...

For the recent LVBots line following competition, my first instinct was to try to come up with some unique alternative design for a robot that would...

The 2pi, built by Mark Moran, is a line following robot based on our 3pi robot. The 2pi uses our 100:1 micro metal gearmotors, motor brackets,...

This PID line follower, originally featured in this Let’s Make Robots post by user Enigmerald, uses our 5" Robot Chassis along with 30:1 MP micro...

Like several of the other engineers here at Pololu, I made a robot to compete in the LVBots Dead Reckoning Competition that took place recently....