This is a merged information page for Item #2118.

View normal product page.

Pololu item #:

2118

Brand:

Pololu

Status:

Active and Preferred

The S7V8A switching step-up/step-down regulator efficiently produces an adjustable output between 2.5 V to 8 V from input voltages between 2.7 V and 11.8 V. Its ability to convert both higher and lower input voltages makes it useful for applications where the power supply voltage can vary greatly, as with batteries that start above but discharge below the regulated voltage. The compact (0.45″ × 0.65″) module has a typical efficiency of over 90% and can deliver 500 mA to 1 A across most combinations of input and output voltages.

Compare all products in Step-Up/Step-Down Voltage Regulators.

Compare all products in Step-Up/Step-Down Voltage Regulators.

|

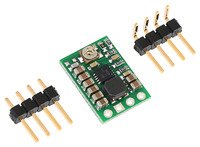

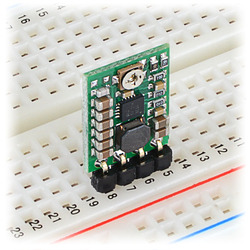

Pololu step-up/step-down voltage regulator S7V8A with included headers. |

|---|

|

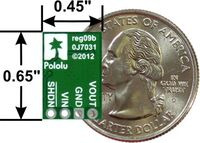

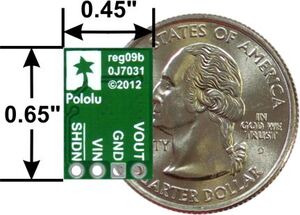

Pololu step-up/step-down voltage regulator S7V8A, S7V8F3, or S7V8F5, bottom view with dimensions. |

|---|

|

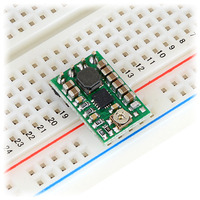

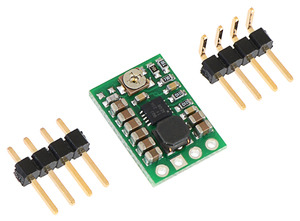

Pololu step-up/step-down voltage regulator S7V8A in a breadboard. |

|---|

|

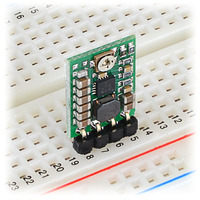

Pololu step-up/step-down voltage regulator S7V8A in a breadboard. |

|---|

|

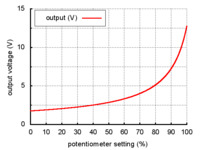

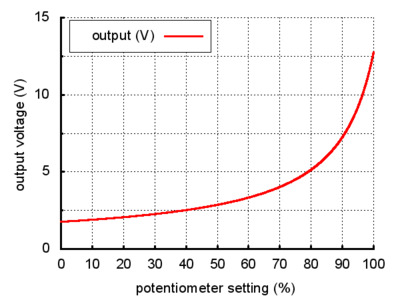

Output voltage settings for the Pololu step-up/step-down voltage regulator S7V8A. |

|---|

|

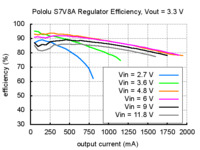

Typical efficiency of Pololu step-up/step-down voltage regulator S7V8A with output voltage set to 3.3 V. |

|---|

|

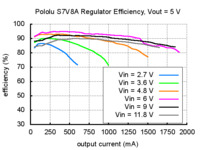

Typical efficiency of Pololu step-up/step-down voltage regulator S7V8A with output voltage set to 5 V. |

|---|

|

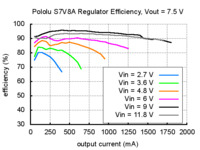

Typical efficiency of Pololu step-up/step-down voltage regulator S7V8A with output voltage set to 7.5 V. |

|---|

|

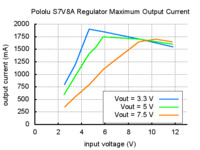

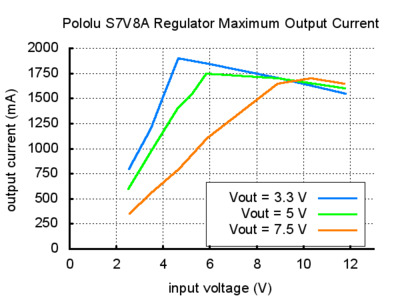

Typical maximum output current of Pololu step-up/step-down voltage regulator S7V8A. |

|---|

|

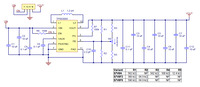

Pololu Step-Up/Step-Down Voltage Regulator S7V8x schematic diagram. |

|---|

|

The Pololu step-up/step-down voltage regulator S7V8A is a switching regulator (also called a switched-mode power supply (SMPS) or DC-to-DC converter) that uses a buck-boost topology. It takes an input voltage from 2.7 V to 11.8 V and increases or decreases the voltage to a user-adjustable output between 2.5 V and 8 V with a typical efficiency of over 90%. The input voltage can be higher than, lower than, or equal to the set output voltage, and the voltage is regulated to achieve the set output voltage.

This flexibility in input voltage is especially well-suited for battery-powered applications in which the battery voltage begins above the desired output voltage and drops below the target as the battery discharges. Without the typical restriction on the battery voltage staying above the required voltage throughout its life, new battery packs and form factors can be considered. For example:

In typical applications, this regulator can deliver up to 1 A continuous when the input voltage is higher than the output voltage (stepping down). When the input voltage is lower than the output voltage (stepping up), the available current decreases as the difference between the voltages increases; please see the graphs at the bottom of this page for a more detailed characterization. The regulator has short-circuit protection, and thermal shutdown prevents damage from overheating; the board does not have reverse-voltage protection.

This regulator is also available with a fixed 3.3 V output or a fixed 5 V output.

|

|

During normal operation, this product can get hot enough to burn you. Take care when handling this product or other components connected to it.

The step-up/step-down regulator has four connections: shutdown (SHDN), input voltage (VIN), ground (GND), and output voltage (VOUT).

The SHDN pin can be driven low (under 0.4 V) to power down the regulator and put it in a low-power state. The quiescent current in this sleep mode is dominated by the current in the 100k pull-up resistor from SHDN to VIN. With SHDN held low, this resistor will draw 10 µA per volt on VIN (for example, the sleep current with a 5 V input will be 50 µA). The SHDN pin can be driven high (above 1.2 V) to enable the board, or it can be connected to VIN or left disconnected if you want to leave the board permanently enabled.

The input voltage, VIN, should be between 2.7 V and 11.8 V. Lower inputs can shut down the voltage regulator; higher inputs can destroy the regulator, so you should ensure that noise on your input is not excessive, and you should be wary of destructive LC spikes (see below for more information).

The output voltage, VOUT, is determined by the trimmer potentiometer position. See the Setting the Output Voltage section below for details.

The four connections are labeled on the back side of the PCB, and they are arranged with a 0.1″ spacing along the edge of the board for compatibility with standard solderless breadboards and perfboards and connectors that use a 0.1″ grid. You can solder wires directly to the board or solder in either the 4×1 straight male header strip or the 4×1 right-angle male header strip that is included.

|

The output voltage can be measured using a multimeter. Turning the potentiometer clockwise increases the output voltage. The output voltage can be affected by a screwdriver touching the potentiometer, so the output measurement should be done with nothing touching the potentiometer.

|

Output voltage settings for the Pololu step-up/step-down voltage regulator S7V8A. |

|---|

Please note that the output voltage can be set below 2.5 V at the low end of the potentiometer’s range and above 8 V at the high end. While this is not likely to damage the regulator, it might not work reliably or its output could become unstable when the output voltage is not within the recommended 2.5-8 V range. In addition, the potentiometer has no physical end stops, which means that the wiper can be turned 360 degrees and into an invalid region in which the output voltage is set to approximately 0.5 V.

The output voltage can be up to 3% higher than normal when there is little or no load on the regulator. The output voltage can also drop depending on the current draw, especially when the regulator is boosting a lower voltage to a higher one (stepping up), although it should remain within 5% of the set voltage.

The efficiency of a voltage regulator, defined as (Power out)/(Power in), is an important measure of its performance, especially when battery life or heat are concerns. As shown in the graphs below, this switching regulator has an efficiency between 80% to 95% for most applications. A power-saving feature maintains these high efficiencies even when the regulator current is very low.

The maximum achievable output current of the board varies with the input voltage but also depends on other factors, including the ambient temperature, air flow, and heat sinking. The graph below shows output currents at which this voltage regulator’s over-temperature protection typically kicks in after a few seconds. These currents represent the limit of the regulator’s capability and cannot be sustained for long periods, so the continuous currents that the regulator can provide are typically several hundred milliamps lower, and we recommend trying to draw no more than about 1 A from this regulator throughout its input voltage range.

|

When connecting voltage to electronic circuits, the initial rush of current can cause voltage spikes that are much higher than the input voltage. If these spikes exceed the regulator’s maximum voltage, the regulator can be destroyed. If you are connecting more than about 9 V, using power leads more than a few inches long, or using a power supply with high inductance, we recommend soldering a 33 μF or larger electrolytic capacitor close to the regulator between VIN and GND. The capacitor should be rated for at least 16 V.

More information about LC spikes can be found in our application note, Understanding Destructive LC Voltage Spikes.

| Size: | 0.45″ × 0.65″ × 0.1″1 |

|---|---|

| Weight: | 0.6 g1 |

| Minimum operating voltage: | 2.7 V |

|---|---|

| Maximum operating voltage: | 11.8 V |

| Maximum output current: | 1 A2 |

| Minimum output voltage: | 2.5 V |

| Maximum output voltage: | 8 V |

| Reverse voltage protection?: | N |

| Maximum quiescent current: | 0.3 mA3 |

| PCB dev codes: | reg09b |

|---|---|

| Other PCB markings: | 0J7031 |

Printable schematic diagram for the S7V8x family of Pololu step-up/step-down voltage regulators: S7V8A, S7V8F3, and S7V8F5.

This DXF drawing shows the locations of all of the board’s holes.

No FAQs available.

Pololu customer Yvon Hache made this 3D-printed aerial photography rig that he shared in a forum post. The rig, trailing 100 feet below the kite,...

The inside of the Geiger counter. The home-made Geiger counter featured in this post by forum user bob_day uses an A-Star 32U4 Micro, LND 7313...