This is a merged information page for Item #2268.

View normal product page.

Pololu item #:

2268

Brand:

SOYO

Status:

Active and Preferred

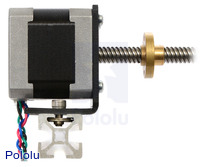

This NEMA 17-size hybrid bipolar stepping motor has an integrated 28 cm (11″) threaded rod as its output shaft, turning it into a linear actuator capable of precision open-loop positioning. The included traveling nut has four mounting holes and moves 40 µm (1.6 mil) per full step; finer resolution can be achieved with microstepping. The stepper motor has a 1.8° step angle (200 steps/revolution) and each phase draws 1.7 A at 2.8 V, allowing for a holding torque of 3.7 kg-cm (51 oz-in).

Alternatives available with variations in these parameter(s): shaft type Select variant…

Compare all products in Stepper Motors or

Compare all products in Stepper Motors or  Linear Actuators.

Linear Actuators.

|

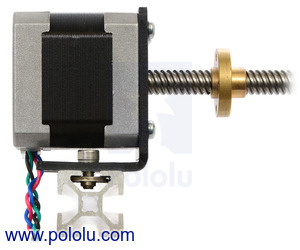

Stepper motor with 28cm lead screw: bipolar, 200 steps/rev, 42×38mm, 2.8V, 1.7 A/phase. |

|---|

|

Stepper motor with 28cm lead screw: bipolar, 200 steps/rev, 42×38mm, 2.8V, 1.7 A/phase. |

|---|

|

NEMA 17-size stepper motors with 18, 28, and 38cm lead screws. |

|---|

|

NEMA 17 stepper motor with lead screw mounted with a stamped aluminum L-bracket. |

|---|

|

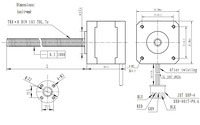

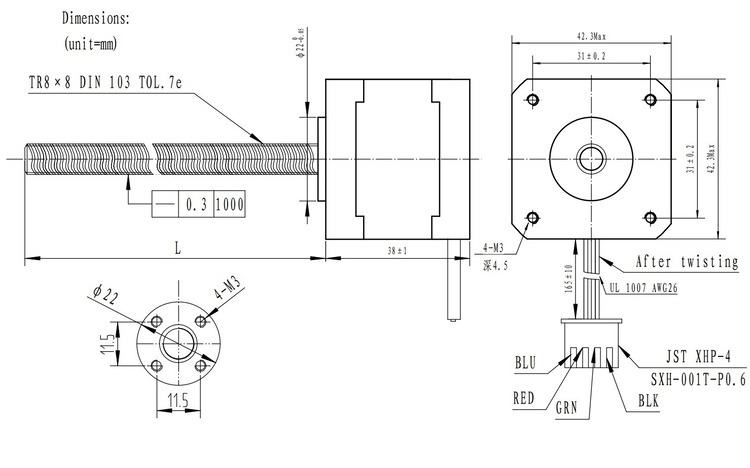

Dimension diagram for the NEMA 17 stepper motors with lead screw (units in mm). |

|---|

|

The JST XHP-4 connector that terminates the leads of the NEMA 17 stepper motor with 28cm lead screw. |

|---|

|

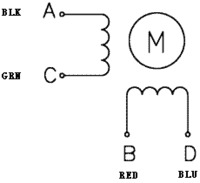

Bipolar stepper motor wiring diagram. |

|---|

|

NEMA 17 stepper motor (item #1200) mounted with a Pololu stamped aluminum L-bracket for NEMA 17 stepper motors. |

|---|

|

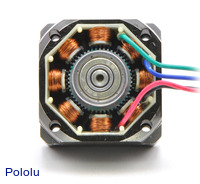

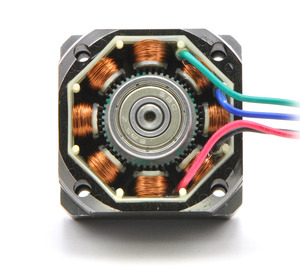

The inside of a bipolar stepper motor (SOYO NEMA 14-size). |

|---|

|

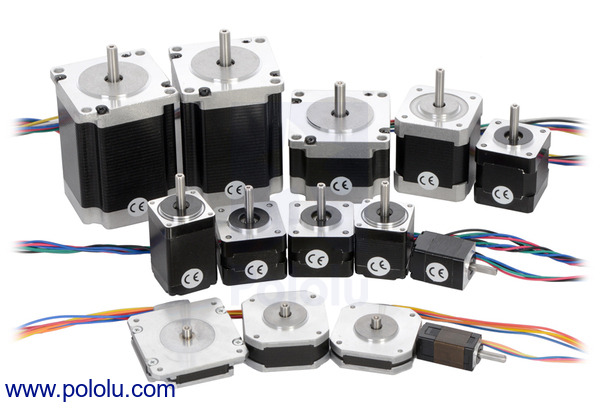

Pololu’s assortment of stepper motors. |

|---|

The lead screw built into this stepper motor extends 28 cm (11″) from the face of the stepper motor and weighs 385 g (13.5 oz). We also carry versions of this stepper motor with an 18 cm and 38 cm lead screw, and we also have the stepper motor available without a lead screw.

|

Stepper motor with 28cm lead screw: bipolar, 200 steps/rev, 42×38mm, 2.8V, 1.7 A/phase. |

|---|

|

When the nut is prevented from rotating, it travels up or down the rod as the motor rotates. |

|---|

This linear positioning drive consists of our 42×38 mm NEMA17 stepper motor with a built-in lead screw in place of the normal output shaft, which makes it easy to move an object or platform in a linear motion with the precision of a stepper motor. Motors like this are especially popular for use in home-built 3D printers (e.g. RepRap) and CNC machines. The stainless steel threaded rod extends from the face of the stepper motor, and since it is integrated into the motor itself, you do not have to deal with bulky shaft couplers or loose set screws. This stepper motor comes in three versions with different length lead screws built in: 18 cm, 28 cm, and 38 cm.

|

NEMA 17-size stepper motors with 18, 28, and 38cm lead screws. |

|---|

The included copper alloy traveling nut (also known as a carriage nut) features a mounting flange with four holes threaded for M3 screws. The nut moves 8.0 mm per full revolution of the lead screw, which allows for a linear resolution of 0.040 mm per full step of the stepper motor. Even smaller step sizes can be achieved through microstepping, which is a feature of many bipolar stepper motor drivers. We recommend the MP6500 stepper motor driver carrier or AMIS-30543 stepper motor driver carrier for use with this stepper motor, the latter of which allows for a linear resolution of 1.25 µm per 1/32 microstep. However, please note that the nut is not spring loaded, so changes in direction will result in loss of positioning precision due to backlash. Extra traveling nuts are also available for purchase separately.

The maximum achievable linear speed depends a lot on the details of the system, including the load and motor supply voltage. Under ideal conditions (e.g. with gradual ramping up of the step rate, a high supply voltage, and no load), we were able to achieve speeds close to 30 cm/s (12 in/s) with the 28 cm lead screw version.

The stepper motor has a 1.8° step angle (200 steps/revolution) and each phase draws 1.7 A at 2.8 V, allowing for a holding torque of 3.7 kg-cm (51 oz-in). The motor has four color-coded wires terminated with a JST XHP-4 connector with 0.1" spacing: black and green connect to one coil; red and blue connect to the other. It can be controlled by a pair of suitable H-bridges (one for each coil), but we recommend using a bipolar stepper motor driver or one of our Tic Stepper Motor Controllers. In particular, the Tics make control easy because they support six different interfaces (USB, TTL serial, I²C, RC, analog voltages, and quadrature encoder) and are configurable over USB with our free configuration utility.

|

|

Our NEMA 17 aluminum bracket offers a variety of options for mounting this stepper motor in your project:

|

NEMA 17 stepper motor with lead screw mounted with a stamped aluminum L-bracket. |

|---|

More specifications are available in the datasheet (63k pdf). Note that while the datasheet is for the stepper motor with 28 cm lead screw, the only difference between the three versions is the length of the lead screw.

The following diagram shows the stepper motor, lead screw, and traveling nut dimensions in mm. The value of L is 182 mm for the stepper motor with 18cm lead screw, 282 mm for the stepper motor with 28cm lead screw, and 382 mm for the stepper motor with 38cm lead screw. Note that the datasheet incorrectly labels the threaded rod as “TR8×3”; it is really a Tr8×8(P2) leadscrew, which is the ISO designation for a trapezoidal metric thread with an 8 mm nominal diameter, 8 mm lead, and 2 mm pitch. (Put more simply, the rod has four independent threads spaced 2 mm apart, so the carriage nut advances 8 mm for each full revolution of the rod.)

|

|

The inside of a bipolar stepper motor (SOYO NEMA 14-size). |

|---|

Stepper motors are generally used in a variety of applications where precise position control is desirable and the cost or complexity of a feedback control system is unwarranted. Here are a few applications where stepper motors are often found:

|

Note: This stepper motor is SOYO part number SY42STH38-1684A.

| Size: |

42.3 mm square × 38 mm (NEMA 17)1 |

|---|---|

| NEMA size: | 17 |

| Weight: | 385 g2 |

| Shaft diameter: | 8 mm |

| Shaft type: | 28 cm threaded rod3 |

|---|---|

| Current rating: | 1680 mA4 |

| Voltage rating: | 2.8 V |

| Holding torque: | 51 oz·in |

| Steps per revolution: | 200 |

| Resistance: | 1.65 Ohm4 |

| Inductance per phase: | 3.2 mH |

| Number of leads: | 4 |

| Lead length: | 16 cm5 |

Note that while this datasheet is specifically for the stepper motor with 28 cm lead screw, the only difference between the three versions (18 cm, 28 cm, and 38 cm) is the length of the lead screw.

Yes. To avoid damaging your stepper motor, you want to avoid exceeding the rated current, which is 600 mA in this instance. All of our stepper motor drivers let you limit the maximum current, so as long as you set the limit below the rated current, you will be within spec for your motor, even if the voltage exceeds the rated voltage. The voltage rating is just the voltage at which each coil draws the rated current, so the coils of your stepper motor will draw 600 mA at 3.9 V. By using a higher voltage along with active current limiting, the current is able to ramp up faster, which lets you achieve higher step rates than you could using the rated voltage.

If you do want to use a lower motor supply voltage for other reasons, consider using our DRV8834 or STSPIN-220 low-voltage stepper motor drivers.

Our new stepper motor bracket is designed to work with typical NEMA 17-size stepper motors like our 42×48mm and 42×38mm units (including...

We have added a compact, powerful new NEMA 17-size stepper motor to our wide selection of stepper motors. This 42×38 mm stepper motor...